Job Shock: Ohio Manufacturer Pulls Plug on Pennsylvania Factory, Cutting Over 100 Positions

Manufacturing

2025-03-07 11:00:01Content

In a significant development for the local industrial landscape, the manufacturing facility is set to cease operations next month. The impending closure marks the end of an era for the long-standing production plant, which has been a cornerstone of the community's economic infrastructure for decades.

Sources close to the company indicate that the decision stems from a combination of strategic restructuring and evolving market dynamics. Employees have been notified of the upcoming shutdown, with management working to provide transition support and potential reassignment opportunities.

The plant's closure is expected to have a notable impact on the local workforce and surrounding business ecosystem. Community leaders are already exploring potential strategies to mitigate the economic consequences and attract new industrial investments to the area.

While the exact details of the closure remain fluid, the company has committed to a responsible and transparent wind-down process that prioritizes the well-being of its dedicated employees and the broader community.

Industrial Transformation: The Imminent Shutdown of a Pivotal Manufacturing Facility

In the dynamic landscape of industrial operations, a significant manufacturing plant stands on the precipice of closure, signaling a profound shift in regional economic dynamics and industrial strategy. This impending shutdown represents more than a mere operational transition, but a complex narrative of economic adaptation, workforce challenges, and strategic realignment in the manufacturing sector.Navigating Industrial Disruption: When Factories Face Inevitable Transformation

Economic Context and Structural Challenges

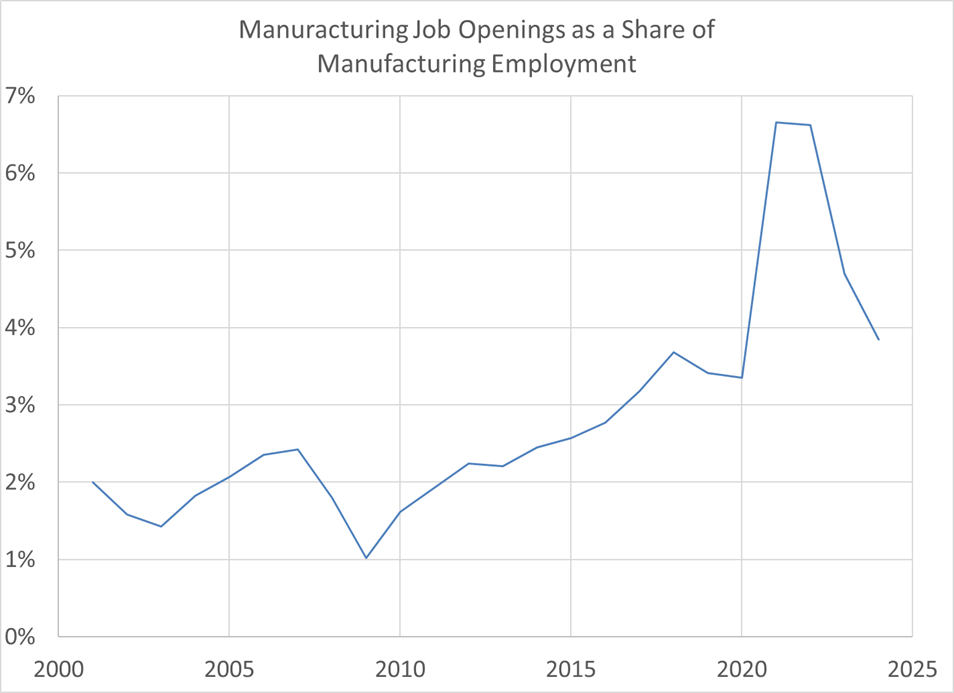

The manufacturing facility's imminent closure unveils a multifaceted story of industrial evolution. Economic pressures, technological disruptions, and shifting market demands have converged to create an environment where traditional manufacturing models are increasingly unsustainable. Global competition, rising operational costs, and the relentless march of technological innovation have rendered many established industrial infrastructures obsolete. Experts argue that such closures are not merely isolated incidents but symptomatic of broader economic restructuring. The plant's shutdown represents a microcosm of larger industrial transformations sweeping across manufacturing landscapes, where adaptability and technological integration have become paramount survival strategies.Workforce Implications and Human Capital Dynamics

The impending closure carries profound implications for the local workforce. Hundreds of skilled workers face potential displacement, triggering complex socioeconomic ripple effects. Beyond immediate job losses, the shutdown challenges regional employment ecosystems, necessitating robust retraining and workforce transition programs. Labor economists suggest that such industrial transitions demand comprehensive support mechanisms. Reskilling initiatives, collaborative partnerships between educational institutions and industries, and targeted economic development strategies become critical in mitigating potential negative employment consequences.Technological Disruption and Industrial Modernization

The plant's closure underscores the relentless technological disruption transforming manufacturing landscapes. Traditional production models are increasingly being supplanted by advanced automation, artificial intelligence, and sophisticated robotics. These technological paradigms demand higher skill levels, more sophisticated infrastructure, and fundamentally different operational approaches. Manufacturing experts emphasize that successful industrial adaptation requires continuous innovation, strategic investments in emerging technologies, and a proactive approach to workforce development. The shutdown, while seemingly disruptive, potentially creates opportunities for more advanced, efficient, and competitive industrial models.Environmental and Sustainability Considerations

Modern industrial transitions are increasingly viewed through environmental sustainability lenses. The plant's closure might represent an opportunity to reimagine industrial infrastructure with heightened environmental consciousness. Potential redevelopment could incorporate green technologies, circular economy principles, and more sustainable operational frameworks. Sustainability consultants argue that such industrial transformations present unique opportunities to align economic productivity with environmental stewardship, potentially creating more resilient and responsible industrial ecosystems.Regional Economic Resilience and Future Outlook

While the plant's closure might initially appear as a setback, it simultaneously represents a potential catalyst for broader economic reinvention. Successful regions have historically demonstrated remarkable adaptability, transforming industrial challenges into opportunities for innovation and economic diversification. Strategic economic development requires holistic approaches that balance immediate workforce needs with long-term vision, technological innovation, and collaborative ecosystem development. The current industrial transition demands nuanced, forward-looking strategies that recognize the complex interdependencies of modern economic systems.RELATED NEWS

Manufacturing

Breaking: Caliber Unleashes AI Powerhouse to Transform Pharma Manufacturing Landscape

2025-03-13 13:00:00

Manufacturing

GoldenHome Breaks Ground: Dallas Facility Marks Major North American Expansion

2025-03-06 16:45:00

Manufacturing

Precision Takes Flight: Stuart's Aerospace Innovator Crafts Critical Aircraft Components at Witham Field

2025-02-26 10:01:31