Manufacturing Momentum Hits Pause: ISM Report Signals Economic Slowdown

Manufacturing

2025-04-02 09:08:21Content

U.S. Manufacturing Sector Experiences Contraction in March 2025

The American manufacturing landscape faced challenges in March 2025, with the sector experiencing a notable downturn. The manufacturing index dropped to 49%, representing a significant decline of 1.3 percentage points from February's 50.3% figure. This contraction signals potential headwinds for the industrial economy.

Key indicators driving the decline include slowing supplier deliveries and escalating production costs. Manufacturers are grappling with supply chain disruptions and increasing price pressures, which are squeezing profit margins and dampening overall economic momentum.

The modest retreat below the critical 50% mark suggests a potential slowdown in industrial activity, raising questions about the sector's near-term resilience and economic outlook. Economists and industry leaders are closely monitoring these trends to assess the broader implications for the U.S. economic recovery.

U.S. Manufacturing Sector Faces Unexpected Contraction: A Deep Dive into March 2025 Economic Indicators

The American manufacturing landscape is experiencing a critical moment of transformation, with recent economic indicators signaling a potential shift in industrial productivity and economic momentum. As global markets continue to navigate complex economic challenges, the latest manufacturing performance metrics reveal intricate dynamics that demand careful analysis and strategic interpretation.Decoding the Economic Pulse: Manufacturing's Delicate Balance

Economic Landscape and Structural Challenges

The United States manufacturing sector has entered a nuanced period of economic recalibration, characterized by a subtle yet significant contraction that demands comprehensive understanding. In March 2025, the sector witnessed a notable decline, with the Purchasing Managers' Index (PMI) dropping to 49%, representing a 1.3 percentage point reduction from February's 50.3% reading. This decline represents more than a statistical fluctuation; it signals potential underlying structural challenges within the industrial ecosystem. Economists and industry analysts are closely examining the multifaceted factors contributing to this contraction. Supply chain disruptions, technological transitions, and global economic uncertainties are converging to create a complex operational environment for manufacturers. The persistent challenges of adapting to rapidly evolving technological landscapes while maintaining competitive pricing and operational efficiency are becoming increasingly pronounced.Supply Chain Dynamics and Pricing Pressures

The manufacturing sector is experiencing unprecedented complexity in supply chain management. Slowing supplier deliveries have emerged as a critical indicator of potential systemic constraints. These delays are not merely logistical inconveniences but represent deeper structural challenges in procurement, transportation, and global trade networks. Simultaneously, increasing prices are adding additional layers of complexity to the manufacturing ecosystem. Raw material costs, labor expenses, and technological investments are creating a challenging pricing environment. Manufacturers are being forced to make strategic decisions about cost management, potentially impacting production volumes, workforce strategies, and long-term investment plans.Technological Innovation and Adaptive Strategies

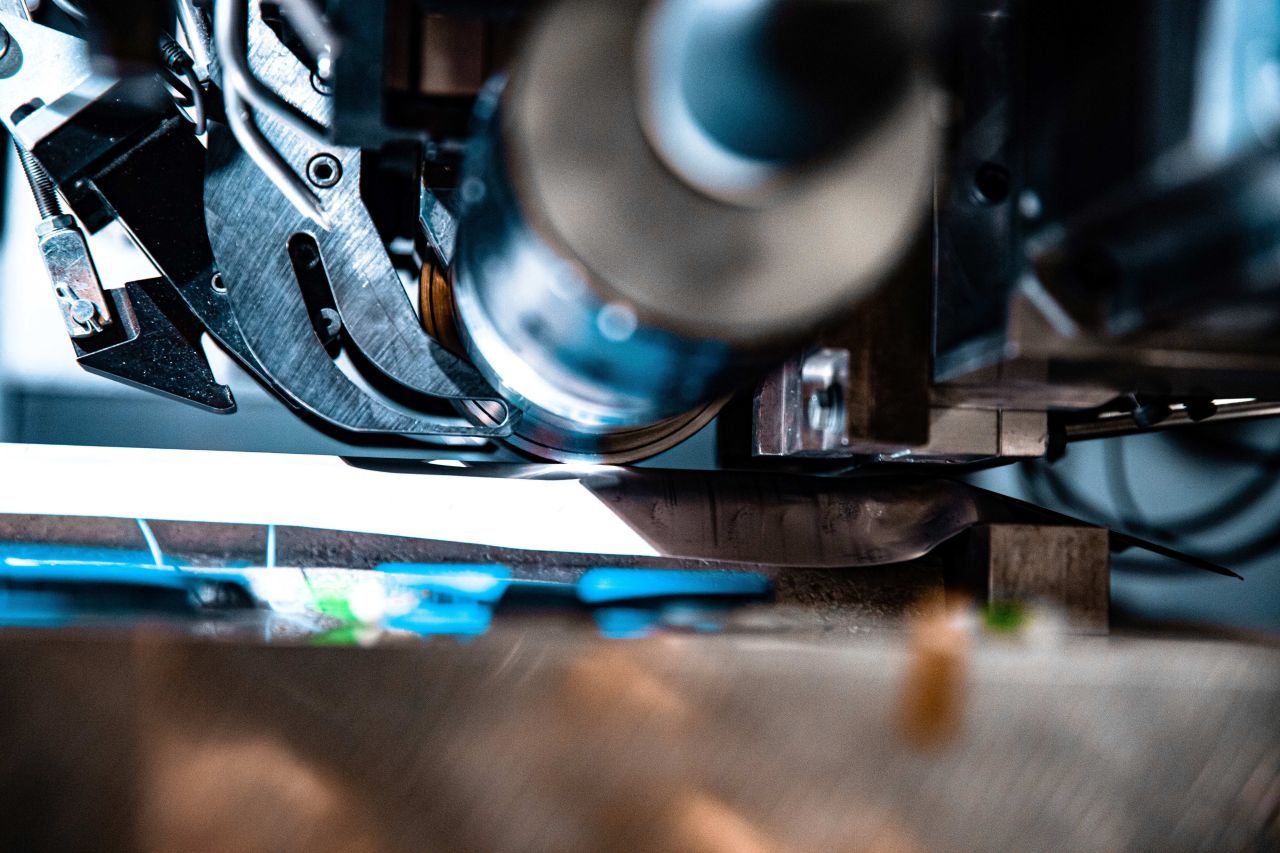

In response to these challenges, forward-thinking manufacturers are accelerating technological innovation and implementing adaptive strategies. Advanced automation, artificial intelligence, and data-driven decision-making are becoming critical tools for maintaining competitiveness and operational resilience. The integration of smart manufacturing technologies offers potential pathways for mitigating current economic pressures. By leveraging real-time data analytics, predictive maintenance, and advanced robotics, companies can optimize production processes, reduce operational inefficiencies, and create more flexible manufacturing ecosystems.Global Economic Context and Future Outlook

The current manufacturing performance must be understood within a broader global economic context. International trade dynamics, geopolitical tensions, and ongoing technological transformations are creating a complex and unpredictable business environment. Manufacturers are required to develop robust, adaptable strategies that can quickly respond to emerging challenges and opportunities. While the current contraction presents immediate challenges, it also offers opportunities for strategic repositioning and innovation. Companies that can effectively navigate these complex dynamics, invest in technological capabilities, and maintain operational flexibility are likely to emerge stronger and more competitive in the evolving industrial landscape. The March 2025 manufacturing data serves as a critical reminder of the ongoing economic transformation, highlighting the need for continuous adaptation, strategic thinking, and innovative approaches in an increasingly complex global marketplace.RELATED NEWS

Manufacturing

Tariff Tremors: How Trump's Trade War Is Shaking US Manufacturing's Foundation

2025-04-17 14:49:43

Manufacturing

Breaking: Caliber Unleashes AI Powerhouse to Transform Pharma Manufacturing Landscape

2025-03-13 13:00:00

Manufacturing

Metal Manufacturing Giant United Performance Metals Supercharges Innovation with Strategic Fabrisonic Buyout

2025-03-24 05:10:21