From Scrap to Salvation: How 3D Printing is Rescuing Military Vehicles on the Battlefield

Manufacturing

2025-03-07 09:53:08Content

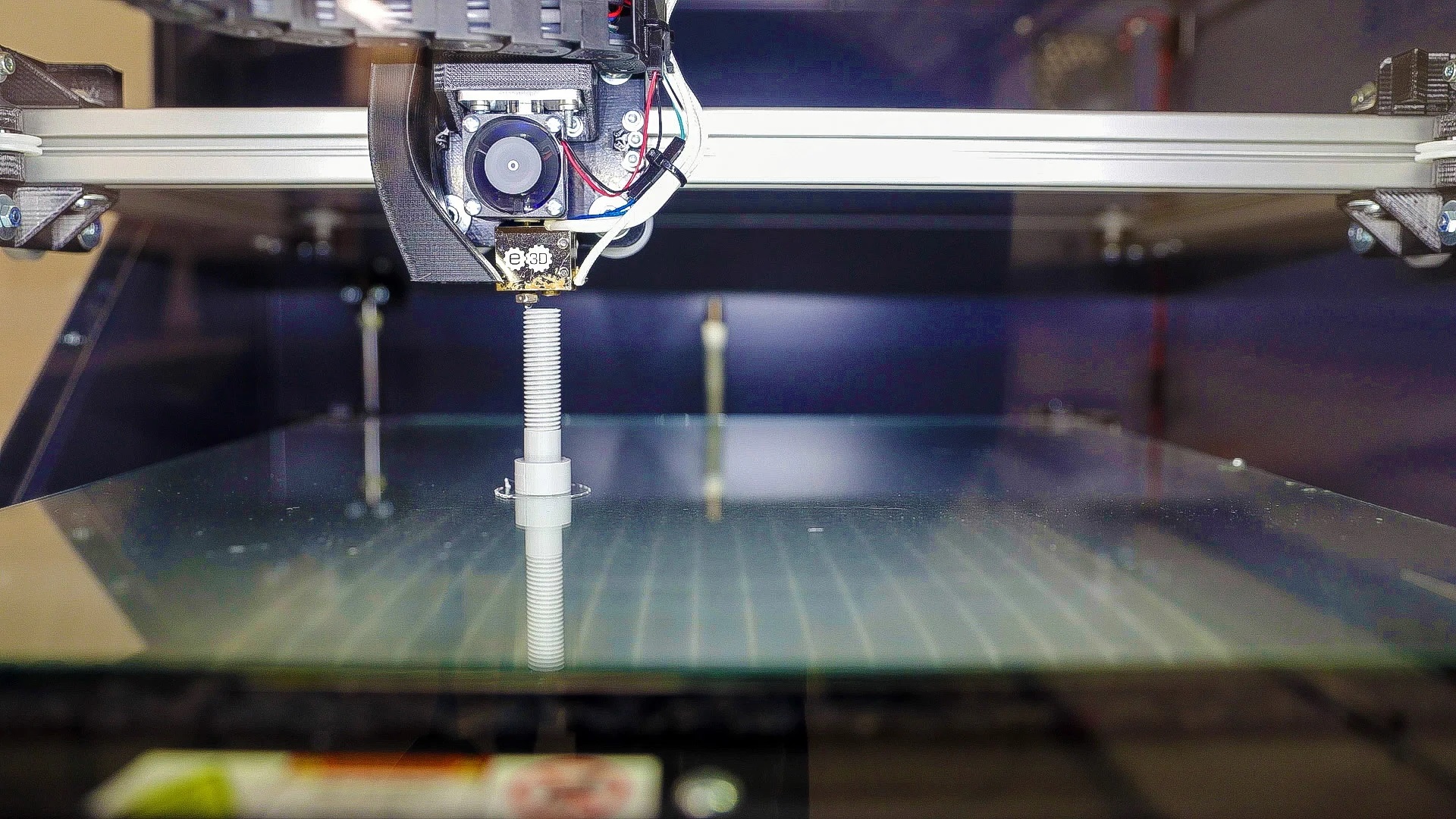

In a groundbreaking initiative, the US Army is revolutionizing vehicle maintenance through cutting-edge additive manufacturing technology. The military's innovative approach aims to dramatically accelerate the restoration of battle-damaged ground vehicles, transforming traditional repair methods with state-of-the-art 3D printing techniques.

By leveraging advanced additive manufacturing processes, Army technicians can now rapidly reconstruct critical vehicle components directly on-site, significantly reducing downtime and logistical challenges. This breakthrough technology allows for precise, custom-fabricated parts to be created quickly, ensuring that military vehicles can be swiftly returned to operational status.

The new manufacturing strategy represents a significant leap forward in military equipment maintenance, offering unprecedented flexibility and efficiency. Instead of relying on complex supply chains and lengthy replacement procedures, troops can now potentially repair damaged vehicles in the field using sophisticated 3D printing technologies.

This approach not only enhances military readiness but also promises substantial cost savings and improved operational resilience. By embracing these advanced manufacturing techniques, the US Army is demonstrating its commitment to technological innovation and adaptive maintenance strategies.

Revolutionary 3D Printing Breakthrough: US Army's Cutting-Edge Vehicle Restoration Strategy

In the rapidly evolving landscape of military technology, the United States Army is pioneering groundbreaking approaches to equipment maintenance and restoration, leveraging advanced manufacturing techniques that promise to transform how military vehicles are repaired and sustained in challenging operational environments.Transforming Military Logistics Through Innovative Manufacturing Solutions

The Future of Battlefield Vehicle Restoration

The United States Army is at the forefront of a technological revolution that could fundamentally reshape military equipment maintenance strategies. By exploring sophisticated additive manufacturing processes, military engineers are developing unprecedented capabilities to rapidly restore and rehabilitate battle-damaged ground vehicles. This innovative approach represents a paradigm shift from traditional repair methodologies, offering unprecedented speed, precision, and cost-effectiveness in vehicle restoration. Advanced manufacturing technologies enable military technicians to create complex replacement parts directly on-site, eliminating lengthy supply chain delays and reducing logistical complexities. The ability to fabricate intricate components using three-dimensional printing techniques means that damaged vehicles can be quickly returned to operational status, minimizing downtime and enhancing overall military readiness.Technological Implications for Military Logistics

The integration of cutting-edge additive manufacturing represents more than just a technical upgrade—it signifies a strategic transformation in military equipment management. By decentralizing repair capabilities and enabling rapid, localized part production, the Army can significantly enhance its operational flexibility and resilience. Modern 3D printing technologies allow for unprecedented customization and rapid prototyping. Military engineers can now design and produce specialized components tailored to specific vehicle models and combat requirements, dramatically reducing reliance on traditional manufacturing and inventory management processes. This approach not only accelerates repair timelines but also reduces overall maintenance costs.Engineering Challenges and Technological Innovations

Implementing advanced manufacturing techniques within military contexts presents complex engineering challenges. Researchers must develop materials and printing processes capable of withstanding extreme environmental conditions, maintaining structural integrity, and meeting rigorous military performance standards. Collaborative efforts between military research institutions, advanced manufacturing laboratories, and private sector technology firms are driving unprecedented innovations. By combining expertise from multiple domains, these interdisciplinary teams are pushing the boundaries of what's possible in equipment restoration and maintenance technologies.Strategic and Economic Considerations

Beyond immediate technical advantages, the Army's investment in additive manufacturing represents a strategic approach to long-term resource management. By reducing dependency on traditional supply chains and enabling more efficient repair processes, these technologies offer substantial economic benefits while enhancing military operational capabilities. The potential cost savings are significant. Traditional replacement parts can be expensive and time-consuming to procure, whereas 3D printing allows for rapid, on-demand production of complex components. This approach not only reduces financial expenditures but also increases the overall responsiveness and adaptability of military logistics systems.Global Technological Leadership

The United States Army's commitment to advanced manufacturing technologies positions the military at the forefront of global technological innovation. By continuously exploring and implementing cutting-edge repair and restoration techniques, the military demonstrates its capacity to adapt and evolve in an increasingly complex technological landscape. These developments extend far beyond military applications, potentially influencing manufacturing practices across multiple industries. The lessons learned and technologies developed through military research often find widespread civilian applications, driving broader technological progress and innovation.RELATED NEWS

Manufacturing

Breaking: The Hidden Challenges of Decentralized Cell Therapy Production Revealed

2025-03-05 00:00:00

Manufacturing

Gears, Sweat, and Innovation: Inside Fresno's Hidden Manufacturing Powerhouse

2025-04-04 05:20:02

Manufacturing

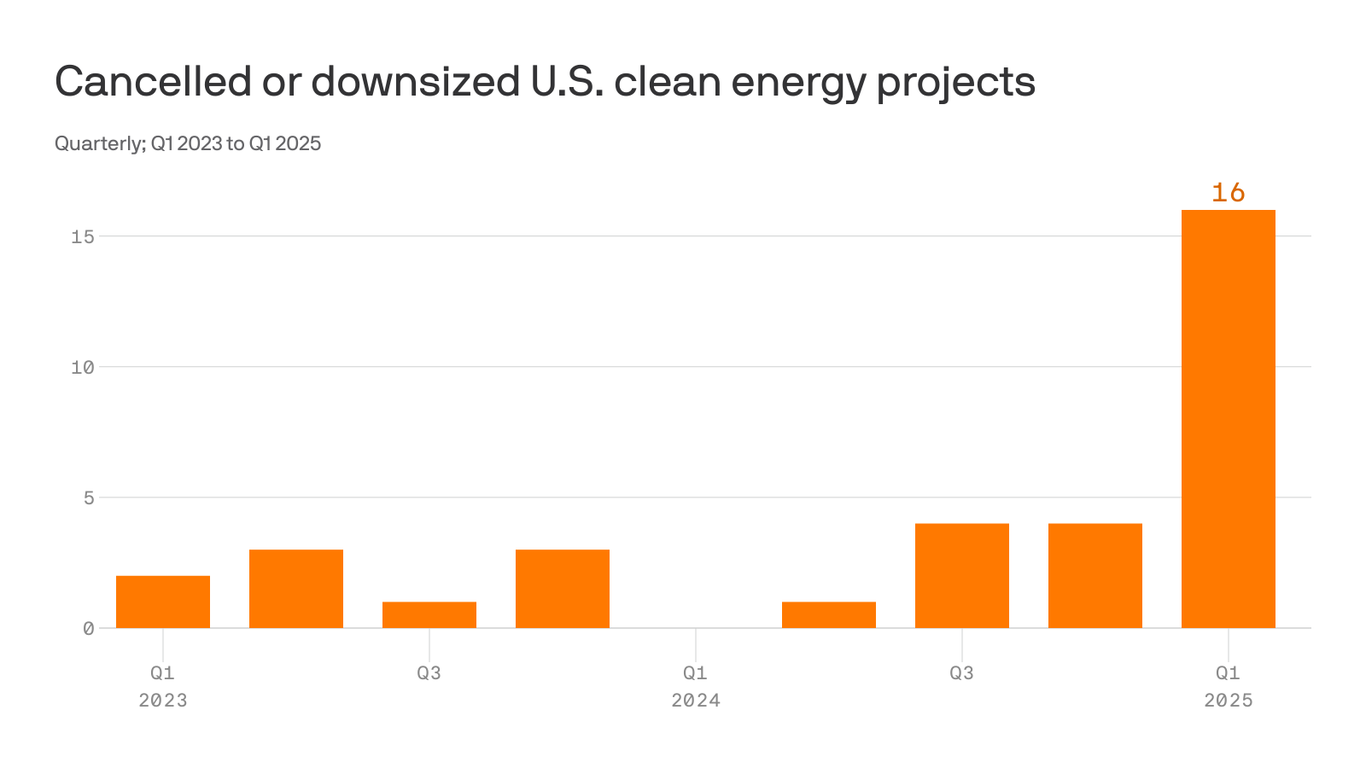

Green Energy Exodus: Massive Project Cancellations Signal Urgent Industry Shift

2025-04-17 08:00:00