Ontario's Manufacturing Future Hangs in the Balance: Why Young Talent Could Be the Game-Changer

Manufacturing

2025-05-02 12:19:35Content

Ontario's Manufacturing Sector Faces Critical Workforce Challenge

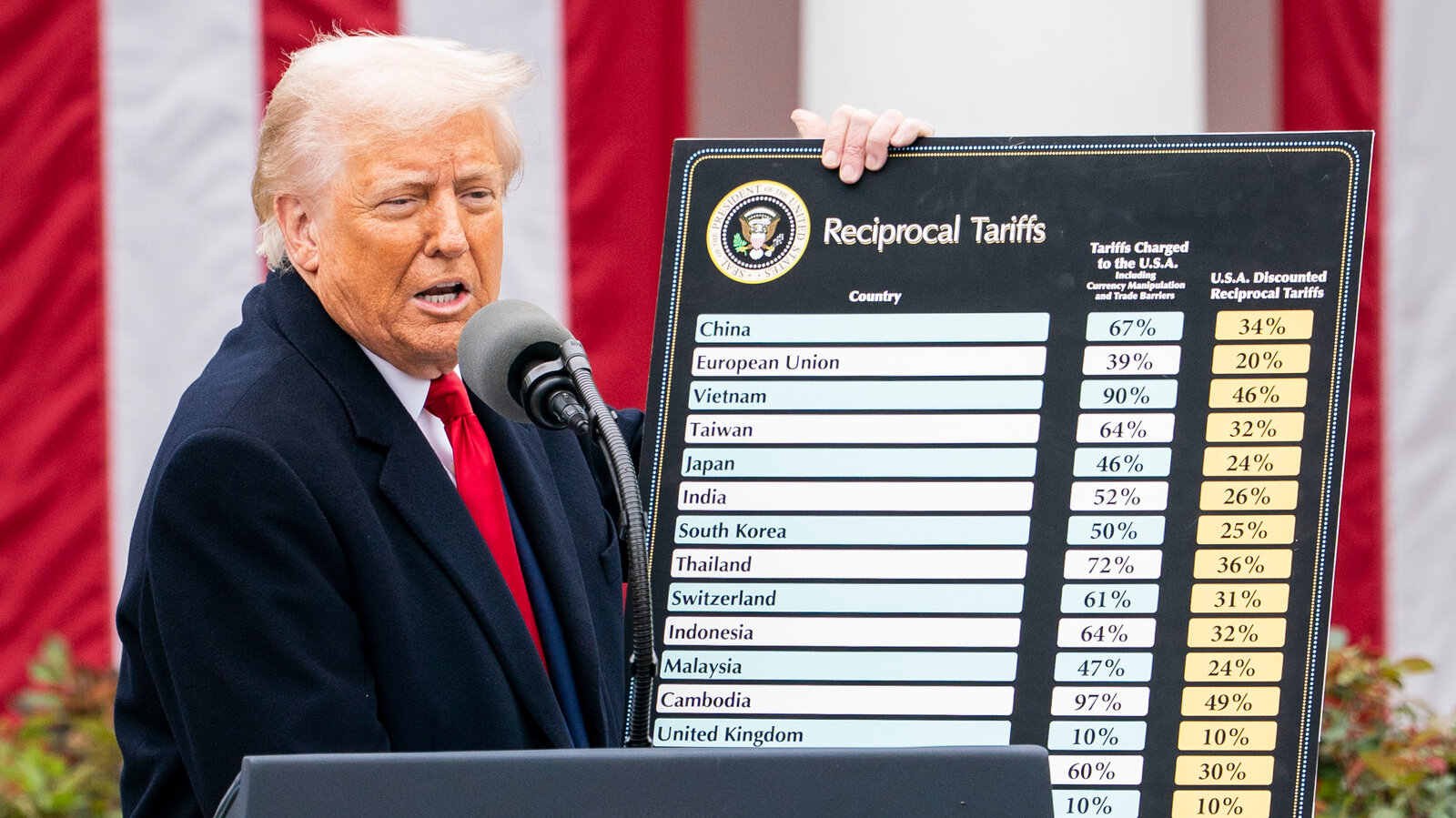

The manufacturing landscape in Ontario is undergoing a dramatic transformation, as local producers simultaneously navigate complex trade tensions and a looming workforce crisis. A compelling new report from Canadian Manufacturers and Exporters (CME) reveals a stark demographic challenge that could significantly disrupt the industry's future.

The study paints a sobering picture: Ontario's manufacturing sector is projected to lose a staggering 22,500 workers annually through 2033 due to retirements. This massive workforce exodus is particularly pronounced in the strategic London to Windsor corridor, a region that has long been the manufacturing heartbeat of the province.

With experienced workers preparing to exit the workforce, manufacturers are facing an urgent imperative to attract, train, and retain a new generation of skilled workers. The challenge extends beyond simple replacement—it's about maintaining the innovative edge and productivity that have defined Ontario's manufacturing sector.

As trade uncertainties continue and technological advancements reshape industrial landscapes, the ability to quickly integrate new talent will be crucial for the sector's long-term sustainability and competitiveness.

Workforce Crisis Looms: Ontario's Manufacturing Sector Faces Unprecedented Talent Drain

The Canadian manufacturing landscape stands at a critical crossroads, confronting a transformative challenge that threatens to reshape the industrial ecosystem. As technological advancements and demographic shifts converge, the sector finds itself navigating a complex terrain of workforce sustainability and economic resilience.Transforming Challenges into Opportunities: The Future of Canadian Manufacturing

The Demographic Workforce Tsunami

The manufacturing sector in Ontario is experiencing an unprecedented demographic transformation that promises to fundamentally alter industrial employment dynamics. Projections indicate a staggering exodus of experienced workers, with approximately 22,500 skilled professionals expected to retire annually through 2033. This massive workforce transition represents more than a statistical challenge—it signals a profound structural reconfiguration of industrial human capital. The implications extend far beyond simple numerical replacement. Each retiring worker carries decades of institutional knowledge, specialized skills, and nuanced understanding of complex manufacturing processes. The potential knowledge gap threatens to create significant operational vulnerabilities across multiple industrial corridors, particularly in the strategically critical London to Windsor manufacturing belt.Technological Disruption and Skill Adaptation

Modern manufacturing demands a radical reimagining of workforce development strategies. Traditional apprenticeship models are rapidly becoming obsolete, replaced by sophisticated training programs that integrate advanced technologies like artificial intelligence, robotics, and data analytics. Companies must now invest not just in recruiting talent, but in creating comprehensive ecosystem of continuous learning and technological adaptation. The emerging workforce requires a hybrid skill set that combines technical proficiency with digital literacy. Manufacturers are increasingly seeking professionals who can seamlessly navigate complex technological environments while maintaining the practical expertise traditionally associated with industrial production. This requires a fundamental restructuring of educational and training paradigms.Economic and Strategic Implications

The workforce transition represents more than an internal industry challenge—it's a critical economic imperative with national implications. Ontario's manufacturing sector contributes substantially to Canada's economic framework, and its ability to maintain competitive edge depends on successfully managing this demographic transformation. Strategic workforce planning now involves complex multi-stakeholder collaborations between educational institutions, government agencies, and private sector entities. Innovative approaches such as targeted immigration programs, advanced vocational training, and public-private partnership models are emerging as potential solutions to address the impending talent shortage.Technological Innovation as a Workforce Strategy

Emerging technologies offer promising pathways to mitigate workforce challenges. Automation, machine learning, and advanced robotics can potentially offset the numerical decline in human workers while simultaneously creating new categories of high-value employment opportunities. However, technological substitution is not a simple solution. It requires substantial investment in infrastructure, comprehensive retraining programs, and a nuanced understanding of how human creativity and technological efficiency can be strategically integrated. The most successful manufacturers will be those who view technological innovation not as a replacement for human talent, but as a complementary enhancement of human capabilities.Regional Economic Resilience

The manufacturing corridors between London and Windsor represent a microcosm of broader national industrial challenges. These regions, historically dependent on traditional manufacturing models, must now rapidly evolve to attract and retain next-generation talent. Local governments and industry leaders are developing innovative strategies including targeted educational incentives, advanced apprenticeship programs, and competitive compensation packages designed to make manufacturing careers attractive to younger professionals. The goal extends beyond mere recruitment—it's about creating a compelling narrative of industrial innovation and career potential.RELATED NEWS

Driving Future Talent: Scholarships Pave the Way for Next-Gen Automotive Manufacturing Professionals