The Great Manufacturing Mirage: Why Factory Jobs Are Fading into Economic Folklore

Manufacturing

2025-04-16 16:45:00Content

The Dream of Reviving American Manufacturing: Why It's More Complex Than We Think

Bringing manufacturing jobs back to the United States isn't simply challenging—it's a complex puzzle with no straightforward solution. Despite political promises and patriotic rhetoric, the reality of reindustrializing America is far more nuanced than simple slogans suggest.

The global economic landscape has fundamentally transformed over decades. Decades of outsourcing, automation, and international trade agreements have systematically dismantled the robust manufacturing infrastructure that once defined American industrial might. Skilled workers have retired, supply chains have been reconfigured, and technological expertise has migrated overseas.

Modern manufacturing demands highly specialized skills, advanced robotics, and sophisticated technological capabilities that can't be quickly reconstructed. The workers who once populated factory floors have either aged out of the workforce or transitioned to entirely different career paths. Retraining an entire generation of workers requires massive investment, time, and a strategic approach that currently seems beyond our national capacity.

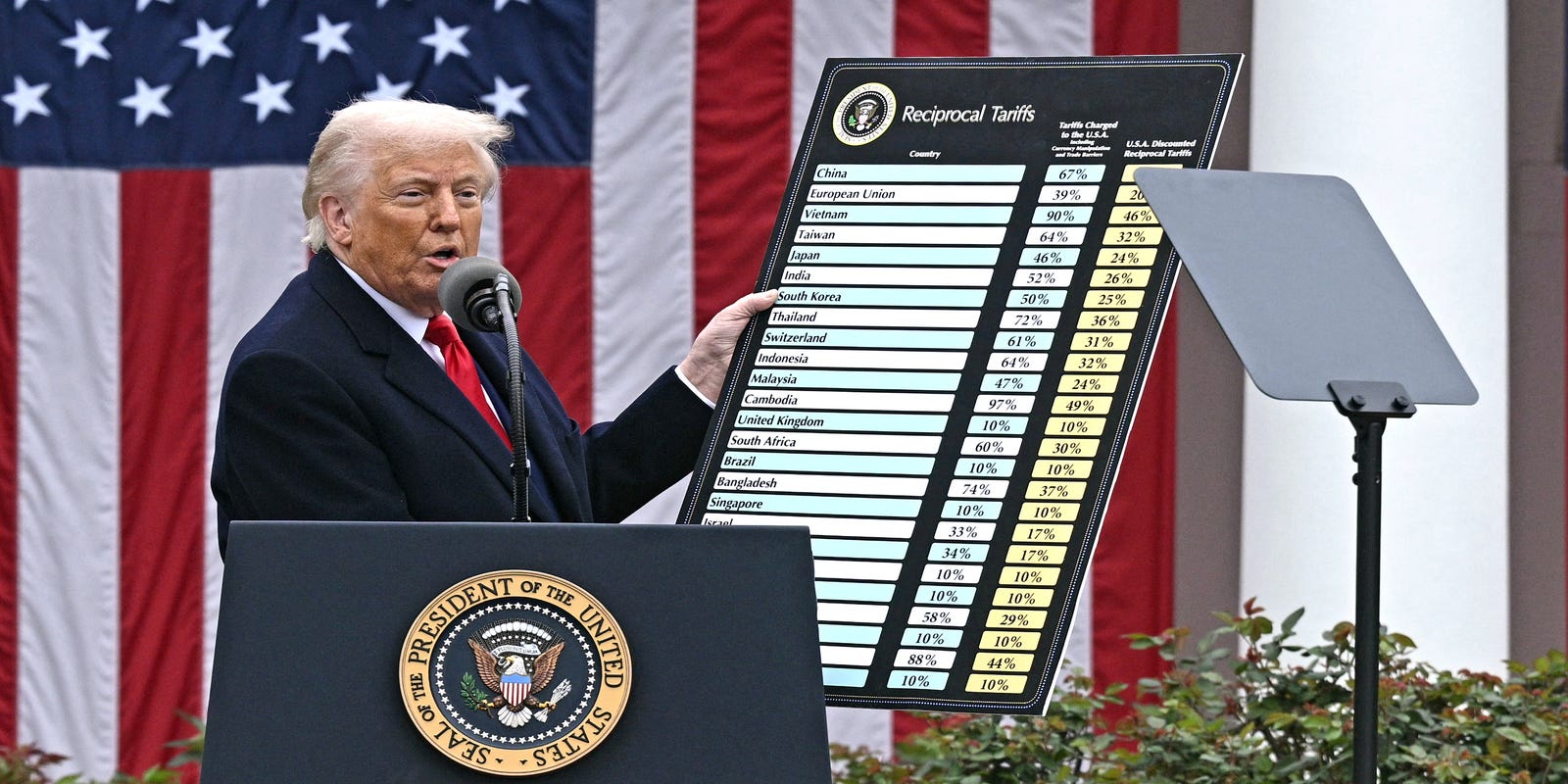

Moreover, international competition, particularly from countries with significantly lower labor costs, creates an almost insurmountable barrier. Emerging economies can produce goods at a fraction of the cost of American manufacturers, making domestic production economically unviable for many industries.

While the nostalgia for America's manufacturing golden age remains powerful, the path to rebuilding is far more complicated than political soundbites suggest. It will require a comprehensive, long-term strategy involving education, technological innovation, and a radical reimagining of industrial policy.

The Vanishing Dream: America's Manufacturing Resurrection Myth

In the heart of America's economic landscape, a persistent narrative echoes through political speeches and industrial corridors—the promise of reviving domestic manufacturing. Yet, beneath the optimistic rhetoric lies a complex tapestry of economic challenges that render this vision more mirage than reality.Rebuilding America's Industrial Heartland: A Herculean Challenge

The Technological Transformation of Manufacturing

Modern manufacturing has undergone a radical metamorphosis, driven by artificial intelligence, robotics, and advanced automation technologies. The factories of today bear little resemblance to the industrial landscapes of previous generations. Sophisticated machines now perform tasks that once required hundreds of human workers, creating an insurmountable barrier to large-scale employment restoration. Sophisticated algorithms and machine learning systems have fundamentally redesigned production processes. Precision robotics can execute complex manufacturing tasks with microscopic accuracy, rendering traditional human labor increasingly obsolete. Companies like Tesla and advanced semiconductor manufacturers demonstrate that cutting-edge production requires minimal human intervention, prioritizing technological efficiency over manual workforce expansion.Global Economic Competitive Dynamics

The global manufacturing ecosystem presents formidable challenges for American industrial revival. Emerging economies like Vietnam, India, and Bangladesh offer dramatically lower labor costs, sophisticated infrastructure, and flexible regulatory environments. These nations have strategically positioned themselves as manufacturing powerhouses, making it economically unfeasible for American companies to compete through traditional employment models. International trade agreements and complex supply chain networks further complicate domestic manufacturing resurrection. Multinational corporations have invested billions in overseas production facilities, creating intricate global networks that cannot be rapidly dismantled or relocated. The economic inertia of these established systems creates substantial barriers to meaningful domestic manufacturing expansion.Skill Gap and Workforce Transformation

The contemporary manufacturing landscape demands unprecedented technical expertise. Modern workers require advanced technological skills, including programming, data analysis, and complex system management. The existing American workforce faces significant challenges in rapidly acquiring these specialized competencies, creating a substantial skills gap that cannot be bridged through traditional training programs. Educational institutions and workforce development programs struggle to keep pace with rapidly evolving technological requirements. The disconnect between current educational frameworks and industry needs creates a systemic barrier to workforce readiness. Specialized technical education requires substantial investment, long-term strategic planning, and a fundamental reimagining of vocational training methodologies.Economic and Policy Constraints

Governmental policies and economic structures present additional obstacles to manufacturing revival. Complex regulatory environments, high operational costs, and intricate tax structures create significant disincentives for large-scale industrial investments. The financial calculus for establishing domestic manufacturing facilities often fails to demonstrate compelling economic advantages. Venture capital and institutional investors increasingly prioritize technology and service sectors over traditional manufacturing. The risk-reward profile of industrial investments appears increasingly unattractive compared to digital economy opportunities. This financial ecosystem further undermines potential manufacturing renaissance efforts.Technological Innovation and Adaptation

The future of manufacturing lies not in recreating past employment models but in embracing technological innovation. Emerging technologies like 3D printing, advanced robotics, and distributed manufacturing networks represent the true frontier of industrial production. These innovations prioritize efficiency, precision, and scalability over traditional employment paradigms. Successful industrial strategies must focus on creating high-value technological ecosystems rather than attempting to resurrect outdated employment models. The most promising path forward involves developing advanced manufacturing capabilities that leverage human creativity and technological innovation.RELATED NEWS

Manufacturing

Manufacturing Momentum: Eurozone's Surprise Economic Pulse Beats Expectations in April

2025-04-23 08:02:23

Manufacturing

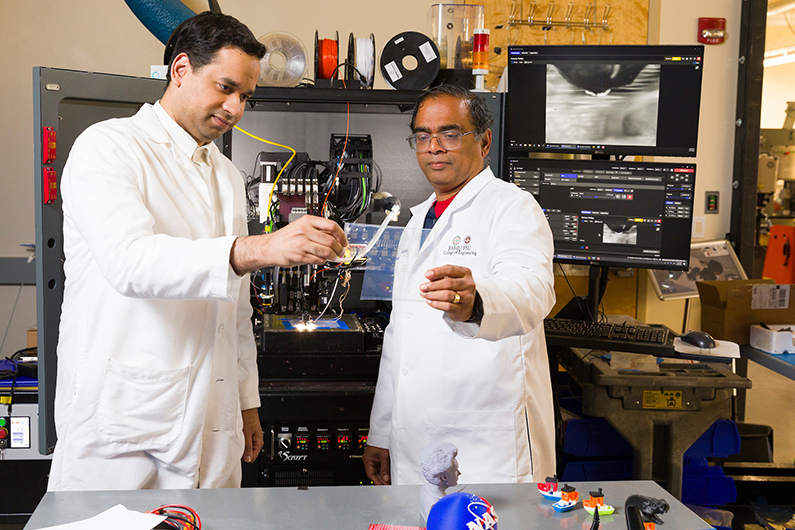

Space Innovation Breakthrough: NASA Pumps $5 Million into Revolutionary Manufacturing Research at FAMU-FSU

2025-04-07 09:11:44

Manufacturing

Solar Power Revolution: Mission Solar Energy Ramps Up Production with Cutting-Edge Cell Manufacturing

2025-03-20 13:15:00