Hidden Profit Killers: How Field Service Operations Are Secretly Bleeding Your Company Dry

Manufacturing

2025-04-14 08:00:57Content

Are Your Field Service Management Systems Holding Your Business Back?

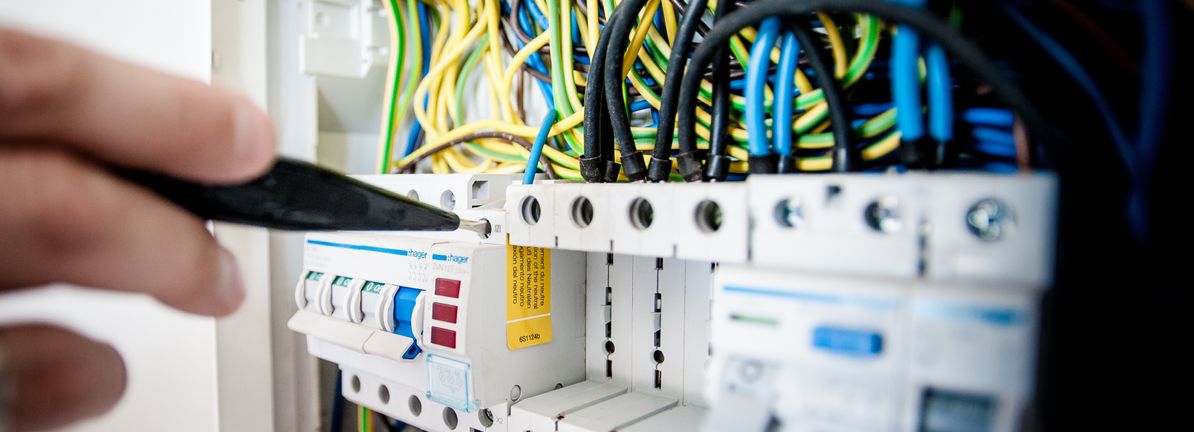

In today's fast-paced business landscape, your field service management (FSM) system can be either a powerful catalyst for growth or a significant roadblock to efficiency. Outdated and ineffective systems aren't just minor inconveniences—they're silent productivity killers that can dramatically impact your bottom line.

Imagine a technology solution that should streamline your operations but instead creates bottlenecks, increases manual work, and prevents your team from reaching its full potential. Many businesses are unknowingly trapped in this cycle, losing valuable time and resources to systems that no longer meet their evolving needs.

The right FSM solution isn't just about tracking work orders—it's about empowering your team, enhancing customer experiences, and driving strategic growth. By identifying and replacing underperforming systems, you can unlock unprecedented operational efficiency and competitive advantage.

Don't let legacy technology dictate your business's future. It's time to assess, upgrade, and transform your field service management approach.

Revolutionizing Industrial Efficiency: The Game-Changing Approach to Factory Management Systems

In the rapidly evolving landscape of industrial operations, manufacturers face an unprecedented challenge of maintaining competitive edge through technological innovation. The critical intersection of operational technology and strategic management has never been more pivotal, with factory management systems emerging as the linchpin of organizational transformation and productivity optimization.Unlock Your Factory's Hidden Potential: Transform Operations Before It's Too Late

The Silent Productivity Killer: Outdated Management Systems

Modern manufacturing environments are increasingly complex ecosystems where technological obsolescence can rapidly erode competitive advantages. Legacy factory management systems often become significant bottlenecks, creating invisible barriers to operational excellence. These antiquated systems not only impede real-time decision-making but also consume substantial financial resources that could be redirected towards innovation and strategic growth. Organizations trapped in technological stagnation frequently experience diminishing returns, with inefficient workflows consuming valuable operational bandwidth. The cumulative impact of these systemic inefficiencies can translate into millions of dollars in potential lost revenue, making technological modernization not just a strategic option but an existential imperative.Decoding the Anatomy of Next-Generation Factory Management Solutions

Contemporary factory management systems represent far more than mere technological upgrades; they are comprehensive strategic frameworks designed to integrate seamlessly across multiple operational domains. These advanced platforms leverage cutting-edge technologies like artificial intelligence, machine learning, and advanced analytics to transform raw operational data into actionable strategic insights. The most sophisticated solutions offer unprecedented levels of real-time monitoring, predictive maintenance capabilities, and adaptive workflow optimization. By creating intelligent, interconnected ecosystems, these systems enable manufacturers to transcend traditional operational limitations, fostering environments of continuous improvement and dynamic responsiveness.Strategic Considerations for Technological Transformation

Selecting an appropriate factory management system requires a nuanced, holistic approach that extends beyond surface-level technological specifications. Decision-makers must conduct comprehensive assessments that evaluate not just immediate technological capabilities but also long-term scalability, integration potential, and alignment with broader organizational strategic objectives. Critical evaluation parameters should include system flexibility, vendor track record, implementation complexity, training requirements, and potential return on investment. Organizations must develop robust change management strategies that facilitate smooth technological transitions, ensuring minimal operational disruption while maximizing employee engagement and technological adoption.Economic and Operational Implications of Strategic System Modernization

The financial implications of implementing advanced factory management systems extend far beyond immediate technological investments. Forward-thinking organizations recognize these platforms as strategic assets capable of generating substantial competitive advantages through enhanced operational intelligence and predictive capabilities. Comprehensive cost-benefit analyses reveal that strategic technological investments can yield exponential returns through improved efficiency, reduced downtime, optimized resource allocation, and enhanced product quality. By transforming data into strategic insights, manufacturers can create more agile, responsive, and resilient operational models.Future-Proofing Manufacturing: The Convergence of Technology and Strategy

As global manufacturing landscapes continue to evolve rapidly, technological adaptability becomes a critical determinant of long-term organizational success. The most successful manufacturers will be those who view technological transformation not as a discrete event but as an ongoing, dynamic process of continuous innovation and strategic reinvention. Emerging technologies like Internet of Things (IoT), edge computing, and advanced machine learning algorithms are progressively reshaping manufacturing paradigms, creating unprecedented opportunities for organizations willing to embrace technological innovation as a core strategic imperative.RELATED NEWS

Manufacturing

Economic Defiance: China's Manufacturing Surge Outpaces US Trade Pressure

2025-03-31 04:09:22

Manufacturing

Revolutionary Cell Therapy Tech: Cellares Wins FDA's Manufacturing Gold Standard

2025-04-02 13:40:00