Inside Apple's Manufacturing Strategy: Tim Cook Breaks Silence on Trump Tariffs and China Controversy

Manufacturing

2025-04-11 15:42:59Content

Apple's Manufacturing Strategy: Tim Cook Reveals the Real Reason Behind Choosing China

In a candid discussion about Apple's global manufacturing approach, CEO Tim Cook has offered a surprising perspective that goes far beyond the traditional narrative of cheap labor. Despite ongoing trade tensions and tariffs, Apple continues to maintain a significant manufacturing presence in China, and Cook's explanation is both nuanced and strategic.

Contrary to popular belief, Cook emphasized that Apple's commitment to China isn't primarily driven by low-cost labor. Instead, he highlighted the country's unparalleled manufacturing ecosystem and infrastructure that makes large-scale, high-precision production possible.

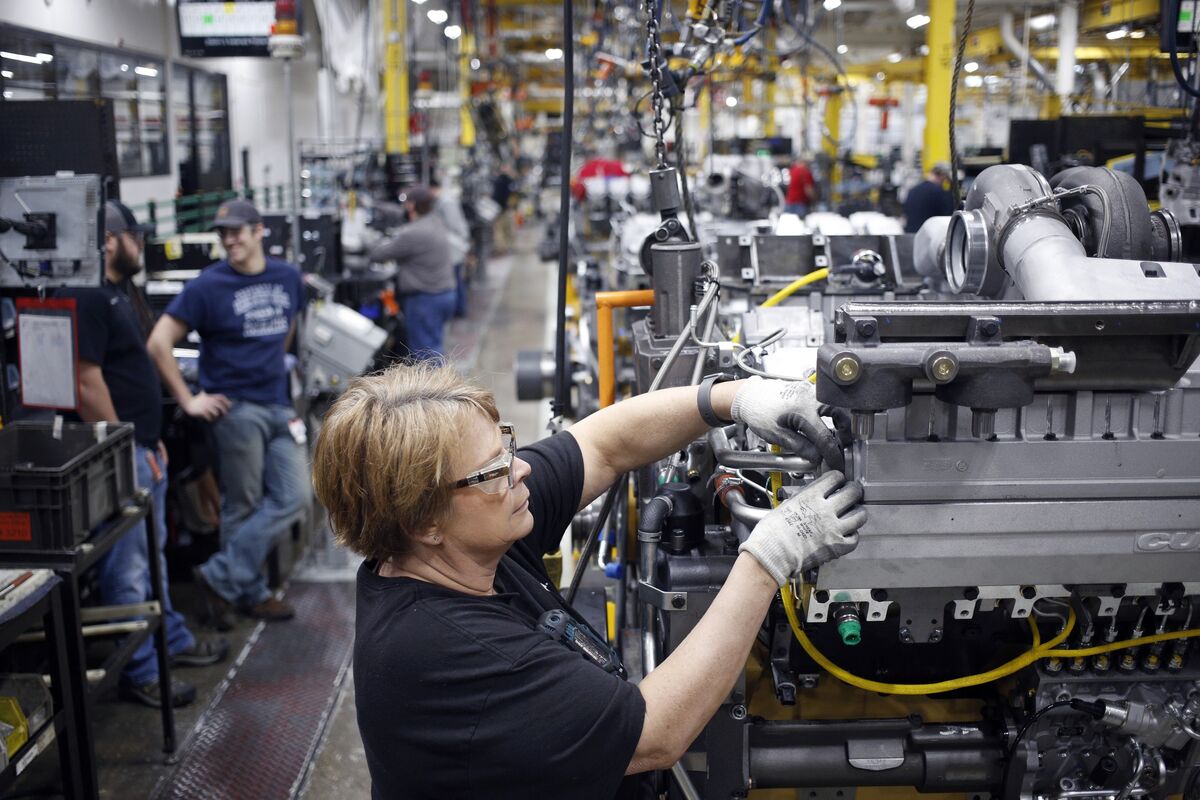

The Complex Manufacturing Landscape

Cook pointed out that China has developed an incredibly sophisticated manufacturing network with remarkable capabilities. This ecosystem includes not just workers, but entire supply chains, specialized skills, and a robust industrial infrastructure that can rapidly scale production of complex technological products.

The Apple CEO's comments come at a time of heightened geopolitical tensions, where many companies are reconsidering their manufacturing strategies. However, Apple remains committed to its Chinese manufacturing partnerships, viewing them as a strategic asset rather than merely a cost-cutting measure.

Beyond Cost: A Strategic Partnership

By choosing China, Apple gains access to a manufacturing environment that can quickly adapt, innovate, and deliver products with exceptional precision and efficiency. This approach underscores Apple's long-term vision of maintaining competitive advantage through strategic global partnerships.

As trade dynamics continue to evolve, Tim Cook's perspective offers a nuanced understanding of international manufacturing that goes well beyond simplistic narratives of cheap labor and cost reduction.

Apple's Global Manufacturing Strategy: Beyond Cost, A Strategic Masterstroke

In the complex landscape of global technology manufacturing, Apple's approach transcends traditional economic paradigms, revealing a nuanced strategy that challenges conventional wisdom about international production networks and corporate decision-making.Decoding the Global Manufacturing Puzzle: More Than Just Economics

The Strategic Significance of China in Apple's Manufacturing Ecosystem

Apple's commitment to Chinese manufacturing represents a sophisticated interplay of geopolitical, technological, and operational considerations that extend far beyond simplistic narratives of cost reduction. The technology giant's relationship with China is a meticulously crafted ecosystem of innovation, infrastructure, and industrial capability that cannot be easily replicated elsewhere. The manufacturing landscape in China offers Apple an unparalleled combination of skilled workforce, robust supply chain infrastructure, and rapid scalability. Unlike other global manufacturing destinations, China provides a comprehensive industrial environment where technological innovation, precision engineering, and massive production capabilities converge seamlessly.Tim Cook's Philosophical Approach to Global Production

Apple's CEO has consistently articulated a vision that transcends mere financial calculations. The company's manufacturing strategy is fundamentally about creating an integrated, responsive, and technologically advanced production network that can adapt rapidly to evolving market demands. Cook's perspective emphasizes the importance of human capital, technological infrastructure, and strategic partnerships over simplistic labor cost considerations. This approach reflects a deeper understanding of global economic dynamics, where value creation is not solely determined by wage differentials but by complex networks of expertise, innovation, and operational efficiency.Technological Infrastructure and Supply Chain Resilience

China's technological ecosystem provides Apple with unprecedented advantages in manufacturing precision, speed, and innovation. The country's investment in advanced manufacturing technologies, robust logistics networks, and comprehensive industrial clusters creates an environment where complex electronic devices can be produced with remarkable efficiency and quality. The intricate supply chain networks in regions like Shenzhen represent a sophisticated industrial symphony, where multiple manufacturers, suppliers, and technological innovators collaborate in creating cutting-edge electronic products. This ecosystem allows Apple to maintain its competitive edge through rapid prototyping, iterative design, and flexible production capabilities.Geopolitical Considerations and Strategic Positioning

Apple's manufacturing strategy in China is also a nuanced response to complex geopolitical dynamics. By maintaining a strong presence in the world's largest electronics manufacturing hub, the company strategically positions itself to navigate potential trade tensions, regulatory shifts, and emerging market opportunities. The relationship between Apple and Chinese manufacturing partners represents a sophisticated form of global economic diplomacy, where technological innovation, economic interdependence, and strategic collaboration intersect. This approach allows Apple to maintain flexibility while leveraging China's unparalleled manufacturing capabilities.Future Outlook: Evolving Manufacturing Paradigms

As global economic landscapes continue to transform, Apple's manufacturing strategy serves as a blueprint for sophisticated, adaptable corporate approaches to international production. The company's model demonstrates that successful global manufacturing is about creating integrated, innovative ecosystems rather than merely seeking the lowest cost production environments. The ongoing evolution of Apple's manufacturing strategy will likely continue to challenge traditional economic assumptions, emphasizing the importance of technological capability, human expertise, and strategic collaboration over simplistic cost considerations.RELATED NEWS

Green Revolution Arrives: LS GreenLink Unveils Cutting-Edge Manufacturing Hub in Virginia

Milestone Achieved: BMW's Spartanburg Plant Rolls Out 7 Millionth Vehicle in Manufacturing Triumph