Revolutionary Catalyst Breakthrough: How Palladium and Gallium Are Rewriting Chemical Manufacturing Rules

Manufacturing

2025-03-29 18:00:01Content

A Revolutionary Leap in Liquid Catalysis: Reshaping the Future of Chemical Manufacturing

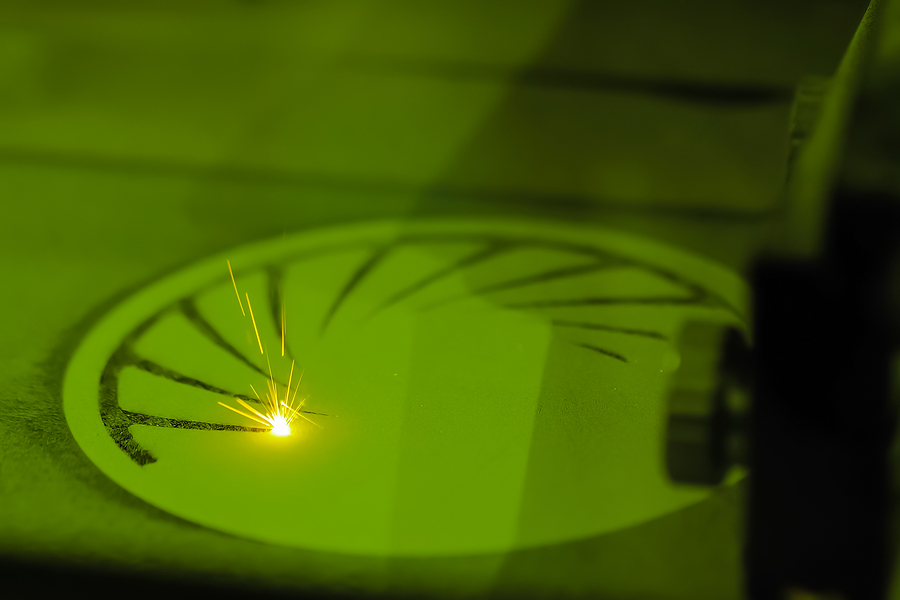

Scientists have unveiled a groundbreaking advancement in liquid catalysis that promises to revolutionize industrial chemical production. This innovative breakthrough is set to transform traditional manufacturing processes, delivering unprecedented improvements in speed, safety, and environmental sustainability.

By developing cutting-edge catalytic techniques, researchers have unlocked a new paradigm of chemical synthesis that dramatically reduces production time and minimizes environmental impact. The breakthrough represents a significant milestone in engineering and chemistry, offering manufacturers a more efficient and responsible approach to creating essential products.

The new liquid catalysis method enables faster chemical reactions, reduces energy consumption, and substantially decreases harmful waste generation. This transformative technology not only enhances industrial productivity but also aligns with global efforts to create more sustainable manufacturing practices.

As industries worldwide seek greener and more efficient production methods, this liquid catalysis breakthrough stands as a beacon of innovation, signaling a new era of smarter, cleaner, and more intelligent chemical manufacturing.

Revolutionary Liquid Metal Catalyst Sparks Industrial Transformation

In the ever-evolving landscape of chemical manufacturing, a groundbreaking technological advancement is poised to redefine the boundaries of industrial production. Scientists and engineers have unveiled a transformative liquid catalysis technique that promises to revolutionize how essential products are developed, marking a pivotal moment in sustainable industrial innovation.Pioneering a New Era of Chemical Manufacturing Efficiency

The Paradigm Shift in Catalytic Processes

Chemical engineering has long grappled with inefficient and environmentally challenging manufacturing methodologies. Traditional catalytic processes have been characterized by slow reaction rates, significant energy consumption, and substantial environmental footprints. The emergence of advanced liquid metal catalysis represents a quantum leap in addressing these fundamental challenges. Researchers have discovered that specialized liquid metal compositions can dramatically accelerate chemical reactions while maintaining unprecedented levels of precision and control. By manipulating molecular interactions at the nanoscopic level, these innovative catalysts enable unprecedented reaction speeds and remarkable energy efficiency.Technological Mechanisms and Scientific Breakthroughs

The underlying mechanism of this revolutionary approach involves intricate molecular engineering. Liquid metal catalysts possess unique structural properties that allow them to dynamically interact with reactant molecules, creating pathways for accelerated chemical transformations. Unlike conventional solid catalysts, these liquid variants can reshape and adapt their molecular configurations in real-time, optimizing reaction conditions instantaneously. Advanced computational modeling and quantum mechanical simulations have been instrumental in understanding and refining these catalytic processes. Researchers have employed sophisticated machine learning algorithms to predict and enhance catalyst performance, pushing the boundaries of what was previously considered scientifically feasible.Environmental and Economic Implications

The environmental benefits of this technological breakthrough cannot be overstated. By reducing energy consumption and minimizing waste production, liquid metal catalysis represents a significant stride towards sustainable industrial practices. Manufacturing processes that once required extensive resources and generated substantial carbon emissions can now be streamlined and environmentally optimized. Economic implications are equally profound. Industries ranging from pharmaceuticals to advanced materials manufacturing stand to benefit from dramatically reduced production costs and increased operational efficiency. The potential for scaling these technologies across multiple sectors suggests a transformative impact on global industrial landscapes.Future Prospects and Research Directions

While the current achievements are remarkable, researchers emphasize that this represents merely the initial phase of a potentially revolutionary technological trajectory. Ongoing research focuses on expanding the range of applicable chemical reactions, improving catalyst durability, and developing more sophisticated molecular design strategies. Interdisciplinary collaborations between chemists, materials scientists, and computational experts are accelerating the development of next-generation catalytic technologies. The convergence of artificial intelligence, nanotechnology, and advanced materials science promises to unlock unprecedented possibilities in chemical manufacturing.Global Industry Implications

International scientific communities and industrial leaders are closely monitoring these developments. The potential for reducing carbon footprints while simultaneously enhancing production capabilities represents a holy grail of modern industrial innovation. Governments and private sector entities are increasingly investing in research and development initiatives aimed at translating these scientific breakthroughs into practical, scalable solutions. Emerging economies and technologically advanced nations alike recognize the transformative potential of liquid metal catalysis. The technology offers a pathway to more sustainable, efficient, and competitive industrial processes that could reshape global manufacturing paradigms.RELATED NEWS

Manufacturing

Breaking: Spotfire's Visual Data Science Revolutionizes Innovation Landscape

2025-05-01 10:47:37

Manufacturing

Innovation Hub: Amsino Unveils Cutting-Edge Manufacturing Complex in Massachusetts

2025-04-15 19:41:22

Manufacturing

Pharma Giant's Massive Bet: Eli Lilly Pumps $27 Billion into US Drug Production Powerhouse

2025-02-28 14:45:51