Manufacturing Meltdown: Trump Tariffs Trigger Economic Tremors

Manufacturing

2025-04-01 14:44:36Content

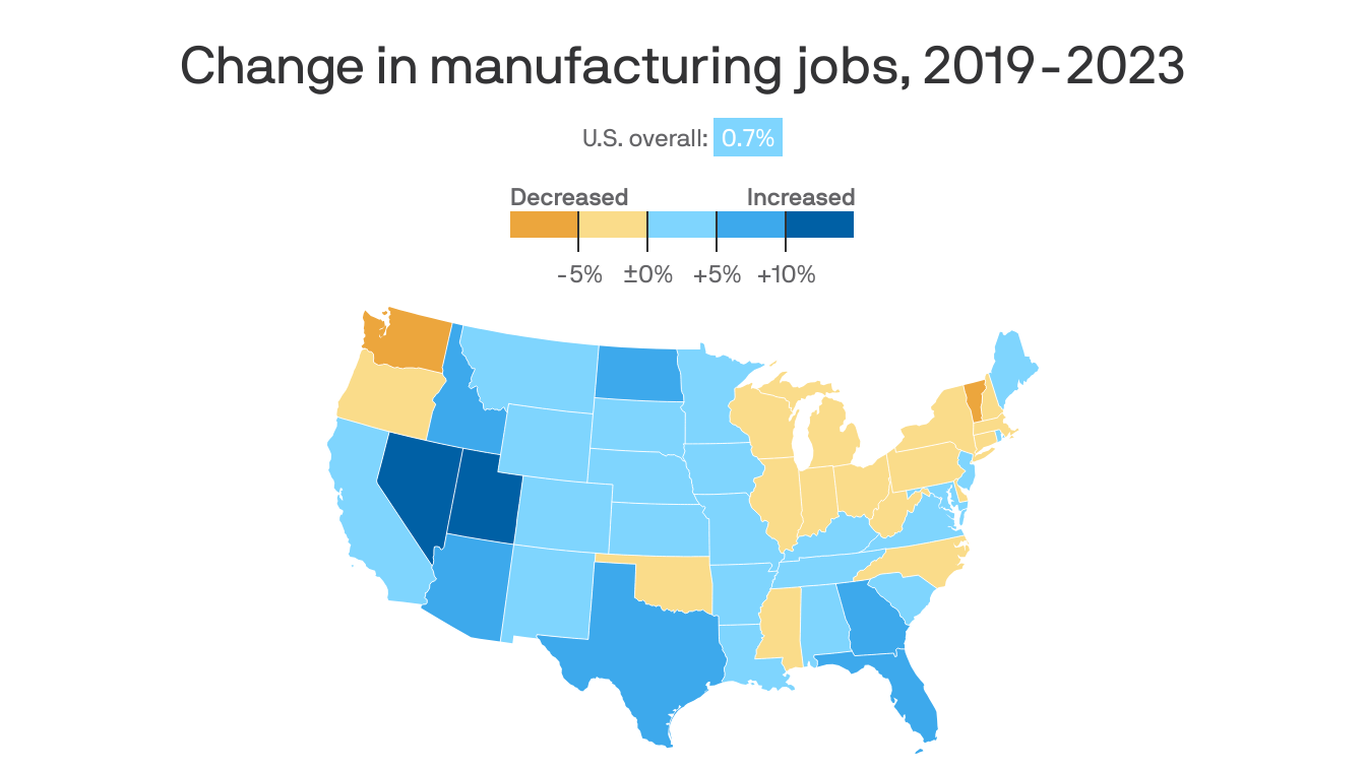

The American manufacturing sector has unexpectedly slipped into economic contraction, marking a significant downturn in industrial activity for the first time in 2023. This challenging shift comes as businesses grapple with the ongoing ripple effects of trade tensions and tariff policies implemented during the previous administration.

Manufacturers across the country are now carefully evaluating the broader economic implications, with supply chain disruptions and increased production costs weighing heavily on their strategic planning. The contraction signals potential challenges ahead, reflecting the delicate balance between international trade dynamics and domestic industrial performance.

Economists and industry leaders are closely monitoring these developments, recognizing that the manufacturing sector's health is a critical indicator of overall economic momentum. The sudden shift underscores the complex interplay between government trade policies and industrial productivity, raising important questions about future economic resilience and growth strategies.

Manufacturing Sector's Dramatic Shift: Unraveling the Economic Ripple Effects of Trade Policies

In the intricate landscape of global economic dynamics, the manufacturing sector stands as a critical barometer of economic health, reflecting the complex interplay of policy decisions, international trade relations, and industrial resilience. Recent developments have signaled a profound transformation that demands comprehensive analysis and understanding.Navigating Uncertain Economic Terrain: A Deep Dive into Industrial Contraction

The Policy Landscape and Its Industrial Implications

The contemporary manufacturing ecosystem has become increasingly sensitive to geopolitical maneuverings, with trade policies emerging as potent catalysts for structural economic shifts. Presidential administrations wield significant influence through tariff strategies, creating intricate ripple effects that penetrate deep into industrial supply chains and production methodologies. Manufacturers find themselves navigating a labyrinthine environment where international trade tensions translate into tangible operational challenges. The implementation of targeted tariffs introduces unprecedented complexity, compelling industries to reassess traditional procurement strategies, recalibrate production models, and explore alternative sourcing mechanisms.Economic Resilience and Adaptive Strategies

Confronted with mounting pressures, manufacturing entities are demonstrating remarkable adaptability. Sophisticated organizations are implementing comprehensive risk mitigation strategies, diversifying supply chains, and investing in technological innovations that enhance operational flexibility. Technological integration has emerged as a critical survival mechanism, with advanced automation, artificial intelligence, and data-driven decision-making processes enabling companies to maintain competitive edges despite challenging macroeconomic environments. These transformative approaches represent more than mere survival tactics; they signify a fundamental reimagining of industrial capabilities.Global Trade Dynamics and Sectoral Transformation

The current manufacturing landscape reflects a nuanced interplay between protectionist policies and global interconnectedness. Tariff implementations create intricate domino effects, influencing not just immediate production capabilities but broader economic ecosystems. International trade relationships are being fundamentally recalibrated, with manufacturers strategically repositioning themselves to navigate increasingly complex regulatory environments. This necessitates unprecedented levels of strategic agility, cross-border collaboration, and innovative thinking.Technological Innovation as an Economic Catalyst

Emerging technologies are revolutionizing manufacturing paradigms, offering unprecedented opportunities for efficiency and adaptability. Machine learning algorithms, advanced robotics, and sophisticated predictive analytics are transforming traditional production models, enabling more responsive and resilient industrial frameworks. The convergence of digital technologies with traditional manufacturing processes represents a profound evolutionary moment, challenging established operational norms and creating entirely new economic possibilities. Companies that successfully integrate these technological innovations are positioning themselves at the forefront of industrial transformation.Socioeconomic Implications and Future Trajectories

The ongoing manufacturing sector contraction transcends mere economic metrics, carrying profound socioeconomic implications. Employment patterns, regional economic structures, and broader national economic strategies are being fundamentally reimagined in response to these dynamic shifts. Policymakers, industry leaders, and economic strategists must collaborate to develop holistic approaches that balance immediate economic imperatives with long-term sustainable development goals. This requires unprecedented levels of interdisciplinary cooperation and forward-thinking strategic planning.RELATED NEWS

Manufacturing

Hyundai's Massive $21B Bet: Supercharging American Manufacturing Landscape

2025-03-24 20:16:13

Manufacturing

Manufacturing Momentum: Germany's Industrial Sector Shows Surprising Resilience in March PMI

2025-03-24 08:30:03