Robotic Revolution: H2 Clipper's Bold Plan to Transform Aerospace Manufacturing

Manufacturing

2025-04-06 15:57:34Content

H2 Clipper Revolutionizes Aerospace Manufacturing with Collaborative Robotic Construction

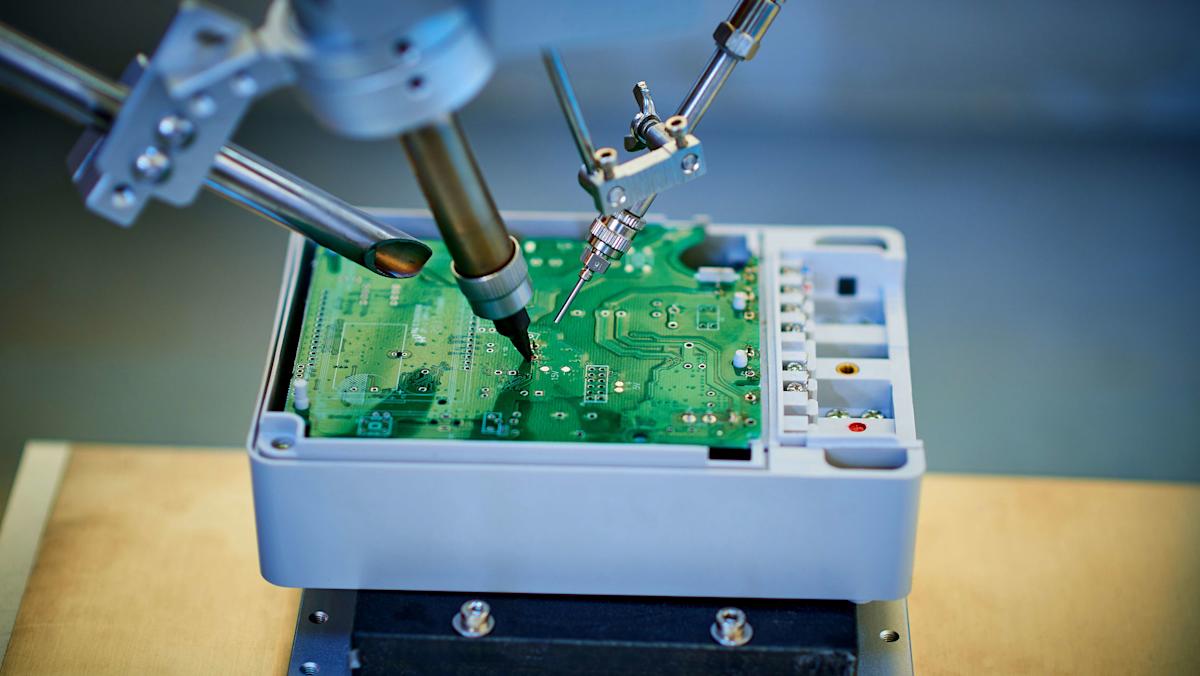

In a groundbreaking leap forward for aerospace engineering, H2 Clipper has unveiled an innovative patent for a cutting-edge robotic construction system. This revolutionary technology harnesses the power of interconnected robots working in seamless collaboration to build massive aerospace structures with unprecedented precision and efficiency.

The patented system represents a significant advancement in manufacturing technology, promising to transform how complex aerospace components are designed and assembled. By deploying a network of intelligent robots that can communicate and coordinate in real-time, H2 Clipper is set to dramatically reduce construction time, minimize human error, and push the boundaries of what's possible in large-scale aerospace structure fabrication.

This breakthrough approach not only showcases the potential of advanced robotics but also signals a new era of manufacturing where machine intelligence and collaborative capabilities can tackle increasingly complex engineering challenges.

Revolutionary Robotic Swarm Technology Transforms Aerospace Manufacturing

In the rapidly evolving landscape of technological innovation, aerospace engineering stands on the brink of a transformative breakthrough. The convergence of advanced robotics and collaborative manufacturing techniques promises to redefine how complex aerospace structures are conceived, designed, and constructed, challenging traditional manufacturing paradigms and opening unprecedented possibilities for large-scale engineering projects.Pioneering the Future of Collaborative Robotic Construction

The Emergence of Swarm Robotics in Aerospace Engineering

Advanced robotic systems are revolutionizing the aerospace manufacturing sector through unprecedented collaborative capabilities. Unlike traditional manufacturing approaches that rely on singular, massive machinery, swarm robotics introduces a dynamic, interconnected network of intelligent machines capable of working in seamless coordination. These sophisticated robotic units can communicate, adapt, and collectively execute complex construction tasks with remarkable precision and efficiency. The fundamental breakthrough lies in the distributed intelligence of these robotic networks. Each individual robot functions not as an isolated entity but as an integral component of a larger, intelligent system. By sharing real-time data, analyzing environmental conditions, and making collective decisions, these robotic swarms can navigate intricate construction challenges that would be insurmountable for conventional manufacturing methods.Technological Mechanisms of Collaborative Robotic Construction

The underlying technological infrastructure enabling these robotic swarms represents a quantum leap in engineering capabilities. Advanced sensor technologies, machine learning algorithms, and sophisticated communication protocols form the backbone of this revolutionary approach. Each robotic unit is equipped with high-precision sensors that continuously monitor spatial relationships, structural integrity, and environmental parameters. Machine learning algorithms enable these robots to learn and adapt dynamically during the construction process. They can instantaneously recalibrate their actions based on emerging challenges, ensuring optimal performance and minimizing potential errors. The communication protocols allow instantaneous data exchange, creating a unified, intelligent construction ecosystem where each robot contributes to the collective objective with unprecedented synchronization.Implications for Aerospace Structure Manufacturing

The potential applications of swarm robotics in aerospace manufacturing are profound and far-reaching. Complex aerospace structures that traditionally required months or years of manual labor can now be conceptualized and constructed with remarkable speed and accuracy. From intricate satellite components to massive spacecraft frameworks, robotic swarms offer unprecedented flexibility and precision. These collaborative robotic systems dramatically reduce human intervention in high-risk manufacturing environments. By minimizing direct human involvement in potentially hazardous construction scenarios, the technology simultaneously enhances worker safety and operational efficiency. The ability to operate in challenging environments—whether extreme temperatures, reduced gravity, or confined spaces—positions these robotic swarms as game-changers in aerospace engineering.Economic and Technological Transformations

Beyond technical capabilities, swarm robotics represents a significant economic paradigm shift. The reduced labor costs, minimized material waste, and accelerated production timelines translate into substantial financial advantages for aerospace manufacturers. Moreover, the scalability of these robotic systems allows for rapid prototyping and iterative design processes that were previously inconceivable. The technological ecosystem surrounding swarm robotics continues to evolve rapidly. Ongoing research and development efforts are focused on enhancing artificial intelligence capabilities, improving inter-robot communication protocols, and developing more sophisticated sensor technologies. Each advancement brings us closer to a future where complex manufacturing processes are executed with unprecedented efficiency and precision.RELATED NEWS

Local Investment Fuels Growth: Utica Backs Precision Manufacturing's $7.5 Million Expansion Leap

Trade War Fallout: How Tariffs Are Silently Crushing American Manufacturing's Competitive Edge