Trump Halts DOGE Collaboration, Deals Blow to Domestic Manufacturing Efforts

Manufacturing

2025-04-03 23:49:39Content

In a surprising turn of events, the Department of General Enterprise (DOGE) has terminated a promising collaborative initiative designed to boost productivity among small and medium-sized manufacturers. The public-private partnership, which aimed to provide critical support and resources to local businesses, has been unexpectedly halted, leaving many industry stakeholders concerned about the potential economic implications.

The program, which was carefully crafted to help smaller manufacturing enterprises enhance their operational efficiency and competitiveness, now faces an uncertain future. Manufacturers who were counting on this strategic alliance to modernize their processes and increase output are left searching for alternative paths to growth and innovation.

While the specific reasons behind the partnership's shutdown remain unclear, the decision has sparked widespread discussion about the challenges facing small and mid-sized manufacturers in today's rapidly evolving economic landscape. Business leaders and economic development experts are closely monitoring the situation, hoping for clarity on the next steps that will support these crucial economic engines.

Manufacturing Revolution: How Small Businesses Are Transforming Productivity Paradigms

In the rapidly evolving landscape of industrial innovation, small and mid-sized manufacturers are facing unprecedented challenges and opportunities that demand strategic reimagining of traditional productivity models. The intersection of technological advancement and economic resilience has created a complex ecosystem where adaptation is not just an option, but a critical survival strategy.Revolutionizing Manufacturing: The Next Frontier of Economic Transformation

The Changing Dynamics of Industrial Productivity

Modern manufacturing environments are experiencing seismic shifts driven by technological disruption and global economic uncertainties. Traditional public-private partnerships have long been considered instrumental in supporting smaller industrial enterprises, yet recent developments suggest a more nuanced approach is emerging. The conventional frameworks of collaboration are being fundamentally challenged, requiring manufacturers to develop more agile and innovative strategies for maintaining competitive advantage. Technological integration has become paramount in this new industrial landscape. Advanced digital technologies, artificial intelligence, and machine learning are no longer luxury investments but essential tools for survival. Small and mid-sized manufacturers must now navigate increasingly complex technological ecosystems, balancing investment costs with potential productivity gains.Strategic Challenges in Manufacturing Collaboration

The dissolution of established public-private partnerships represents more than a mere administrative change; it signals a profound transformation in how industrial collaboration is conceptualized. Manufacturers are now compelled to develop more autonomous and self-reliant approaches to productivity enhancement. Economic resilience demands a multifaceted strategy that goes beyond traditional support mechanisms. Companies must now invest in internal capabilities, workforce training, and technological infrastructure to remain competitive. The era of external dependency is gradually giving way to a more proactive and self-directed model of industrial development.Technological Innovation as a Competitive Differentiator

Cutting-edge technologies are redefining the manufacturing landscape, offering unprecedented opportunities for efficiency and innovation. Machine learning algorithms, predictive maintenance systems, and advanced robotics are transforming production processes, enabling smaller manufacturers to compete with larger, more established industrial players. The integration of these technologies requires not just financial investment but a fundamental cultural shift. Organizations must cultivate a mindset of continuous learning and adaptability, recognizing that technological proficiency is now a critical determinant of long-term success.Economic Implications and Future Outlook

The current industrial transformation extends far beyond individual organizational strategies. It represents a broader economic recalibration where agility, innovation, and technological sophistication are becoming the primary drivers of competitive advantage. Manufacturers must now view technological investment as a strategic imperative rather than an optional enhancement. The ability to rapidly adapt, integrate new technologies, and develop innovative solutions will increasingly differentiate successful enterprises from those struggling to maintain relevance in a rapidly changing economic landscape.Human Capital: The Ultimate Competitive Edge

While technological tools are crucial, the human element remains the most significant factor in manufacturing productivity. Workforce development, skills training, and creating adaptive organizational cultures are becoming as important as technological investments. Companies that can successfully blend technological innovation with robust human capital strategies will be best positioned to thrive in the emerging industrial ecosystem. This requires a holistic approach that values continuous learning, encourages creativity, and provides employees with the tools and opportunities to grow alongside technological advancements.RELATED NEWS

Manufacturing

Pharma's Alarm: Trump Tariffs Could Spike Drug Prices and Limit Patient Access

2025-03-26 21:12:04

Manufacturing

Manufacturing Lifeline in Jeopardy: Rural Minnesota Program Faces Funding Squeeze

2025-04-29 21:42:12

Manufacturing

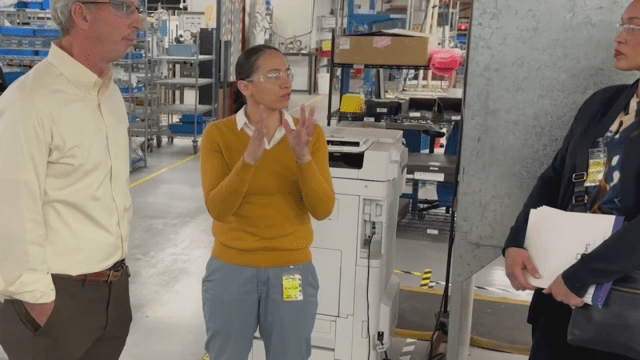

Local Congresswoman Tours Manufacturing Facility, Highlights Funding Challenges

2025-04-15 23:43:59