Manufacturing Revolt: Trump's Tariff Promise Sparks Industry Rebellion

Manufacturing

2025-04-03 19:14:56Content

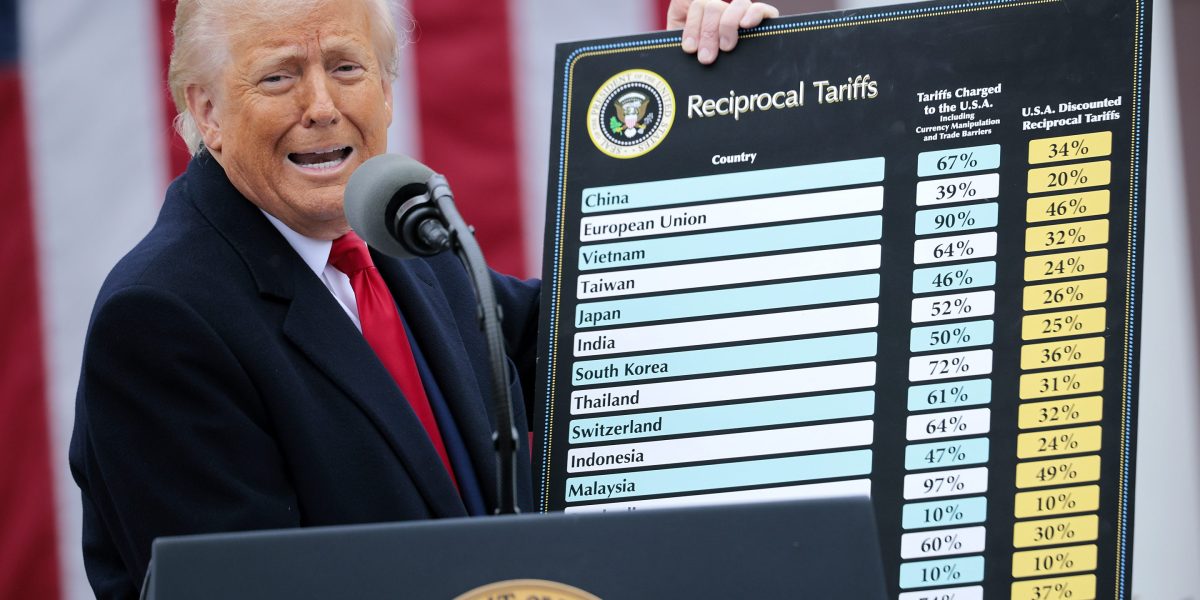

While President Biden remains optimistic about the manufacturing sector, industry leaders are painting a more cautious picture. Manufacturers across the country are increasingly worried about the dual challenges of escalating tariffs and surging raw material costs. These economic pressures are creating significant uncertainty for businesses, casting a shadow over the administration's positive economic narrative.

The stark contrast between the presidential perspective and the ground-level manufacturing sentiment highlights the complex economic landscape facing American industries. Executives are grappling with rising expenses that threaten to squeeze profit margins and potentially slow down production and investment. Unlike the administration's hopeful outlook, these business leaders are experiencing firsthand the financial strain of current economic conditions.

Raw material prices continue to climb, forcing manufacturers to make difficult decisions about pricing, production, and long-term strategic planning. The combination of trade tensions and material cost increases is creating a challenging environment that goes beyond the optimistic projections presented by political leadership.

Industrial Uncertainty: The Hidden Challenges Facing Manufacturing's Global Landscape

In the complex and ever-evolving world of global manufacturing, economic dynamics are shifting rapidly, presenting unprecedented challenges that demand nuanced understanding and strategic adaptation. The current industrial ecosystem is experiencing profound transformations driven by geopolitical tensions, technological disruptions, and intricate economic pressures that are reshaping traditional production paradigms.Navigating Economic Turbulence: A Critical Analysis of Manufacturing's Future

Economic Volatility and Global Supply Chain Disruptions

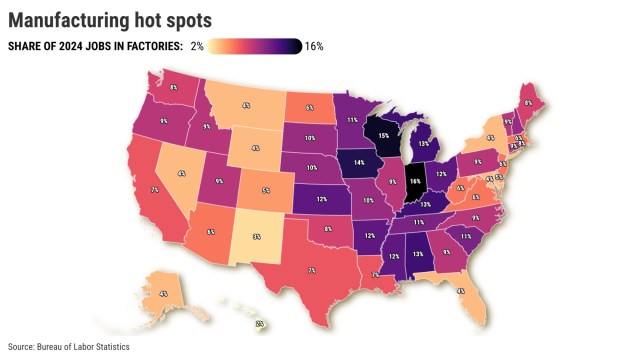

The contemporary manufacturing sector finds itself at a critical crossroads, confronting multifaceted challenges that extend far beyond conventional economic models. Manufacturers are experiencing unprecedented volatility, characterized by unpredictable tariff landscapes and escalating raw material costs that threaten operational sustainability. These economic pressures are compelling industry leaders to reevaluate their strategic approaches, implementing sophisticated risk mitigation strategies that can withstand complex global economic fluctuations. Emerging economic indicators suggest a profound restructuring of international trade dynamics, where traditional manufacturing strongholds are being challenged by emerging economic powerhouses. Companies must now navigate an increasingly complex terrain marked by geopolitical uncertainties, technological innovations, and rapidly changing consumer demands.Technological Transformation and Adaptive Manufacturing Strategies

Modern manufacturing enterprises are increasingly recognizing the imperative of technological integration as a fundamental survival mechanism. Advanced technologies like artificial intelligence, machine learning, and sophisticated robotics are no longer optional luxuries but critical components of competitive strategy. These technological interventions enable manufacturers to optimize production processes, reduce operational inefficiencies, and create more resilient supply chain ecosystems. The integration of digital technologies represents a fundamental paradigm shift, allowing companies to develop more agile, responsive, and data-driven manufacturing models. By leveraging real-time analytics and predictive modeling, organizations can anticipate market changes, mitigate potential disruptions, and maintain competitive advantages in an increasingly complex global marketplace.Raw Material Dynamics and Economic Resilience

The escalating costs of raw materials represent a significant challenge for manufacturers worldwide. These increasing expenses are not merely incremental but represent fundamental shifts in global resource economics. Manufacturers must develop sophisticated strategies that balance cost management with sustainable procurement practices, exploring alternative sourcing mechanisms and innovative material substitution techniques. Strategic diversification of supply chains has emerged as a critical risk management approach. By reducing dependency on single-source suppliers and geographical regions, companies can create more robust and adaptable procurement frameworks that can withstand potential economic disruptions and geopolitical uncertainties.Regulatory Landscape and Compliance Challenges

The contemporary manufacturing environment is characterized by increasingly complex regulatory frameworks that demand unprecedented levels of compliance and strategic adaptation. International trade regulations, environmental standards, and labor policies are continuously evolving, requiring manufacturers to maintain exceptional levels of organizational agility and regulatory intelligence. Successful organizations are developing comprehensive compliance strategies that integrate legal expertise, technological solutions, and proactive risk management approaches. These holistic frameworks enable companies to navigate intricate regulatory landscapes while maintaining operational efficiency and competitive positioning.Future Outlook and Strategic Imperatives

As global economic dynamics continue to transform, manufacturers must embrace a philosophy of continuous adaptation and strategic innovation. The ability to anticipate market changes, leverage technological advancements, and develop resilient operational models will distinguish successful enterprises from those struggling to maintain relevance. The manufacturing sector stands at a critical juncture, where traditional approaches are being fundamentally challenged by technological disruption, economic volatility, and evolving global dynamics. Organizations that can effectively navigate these complex challenges will emerge as leaders in the next phase of industrial evolution.RELATED NEWS

Manufacturing

Trade Tensions Loom: California's Manufacturing Powerhouse Braces for Uncertain Future

2025-04-18 14:01:31

Manufacturing

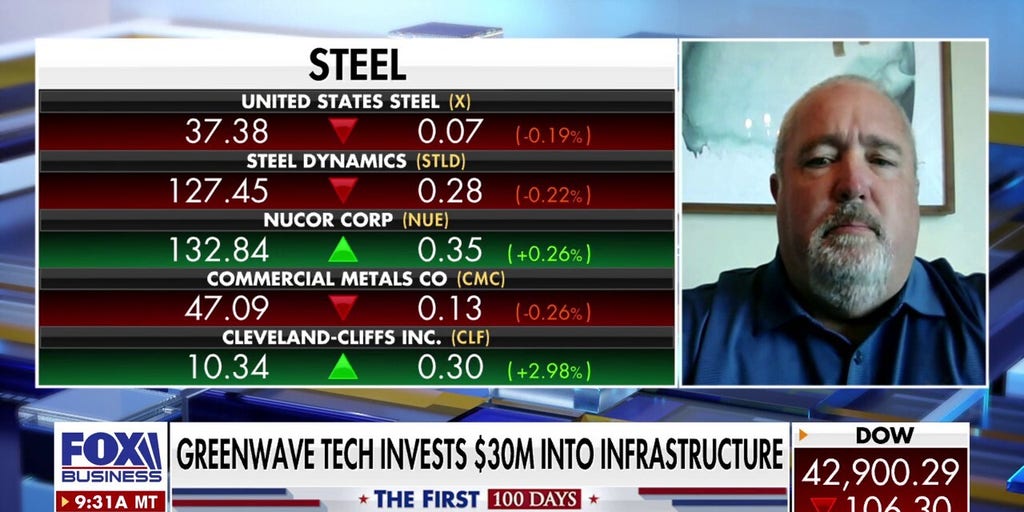

Steel's Comeback: How Trump's Tariffs Are Leveling the Industrial Battlefield

2025-03-06 17:36:50

Manufacturing

Trade War Squeeze: Utah Entrepreneurs Scramble to Reinvent Supply Chains

2025-04-11 01:18:53