Tariff Tango: How New Jersey Manufacturers Could Win or Lose in Trump's Trade War

Manufacturing

2025-04-10 08:30:59Content

Despite local manufacturing efforts, many products still face challenges of global interdependence. The intricate web of global supply chains means that even domestically produced goods may rely on imported materials or specialized components from abroad. Manufacturing equipment often requires precision parts sourced from international suppliers, creating a complex landscape of production that transcends national boundaries.

Local manufacturers continue to navigate these challenges, seeking innovative solutions to reduce dependency on foreign inputs while maintaining high-quality production standards. The reality is that global interconnectedness remains a critical factor in modern manufacturing, highlighting the delicate balance between local innovation and international resource networks.

Global Supply Chains Unraveled: The Hidden Complexity of Modern Manufacturing

In an increasingly interconnected world, manufacturing has transcended traditional boundaries, creating a complex web of international dependencies that challenge our understanding of production and economic resilience. The intricate dance of global trade reveals vulnerabilities and opportunities that reshape industrial landscapes in ways previously unimagined.Navigating the Intricate Maze of Global Production Challenges

The Globalization of Manufacturing Ecosystems

Modern manufacturing represents a sophisticated symphony of international collaboration, where production processes are no longer confined to singular geographical boundaries. Companies increasingly find themselves navigating a labyrinthine network of global suppliers, technological dependencies, and geopolitical complexities that fundamentally transform traditional industrial paradigms. Manufacturers today confront unprecedented challenges in maintaining supply chain integrity. Each production line potentially represents a delicate constellation of international components, where a disruption in one region can cascade into systemic vulnerabilities across multiple industrial sectors. The intricate interdependencies demand unprecedented levels of strategic planning and adaptive capabilities.Technological Interdependence and Material Sourcing Dynamics

Contemporary manufacturing environments are characterized by profound technological interdependence, where machinery, replacement parts, and critical components frequently originate from diverse international sources. This global sourcing strategy introduces remarkable flexibility but simultaneously creates potential fragility within production ecosystems. The procurement landscape has evolved dramatically, with companies developing sophisticated strategies to mitigate risks associated with international material sourcing. Advanced predictive analytics and real-time monitoring technologies enable organizations to anticipate potential disruptions, creating more resilient and adaptable manufacturing frameworks.Economic Resilience in a Volatile Global Marketplace

Economic resilience has emerged as a critical strategic imperative for modern manufacturers. Organizations must continuously recalibrate their approaches, balancing cost-effectiveness with risk mitigation strategies that protect against potential supply chain interruptions. Successful companies are developing multifaceted approaches that include diversifying supplier networks, investing in localized production capabilities, and developing robust contingency frameworks. These strategies represent sophisticated responses to the complex challenges presented by an increasingly unpredictable global economic environment.Technological Innovation and Supply Chain Transformation

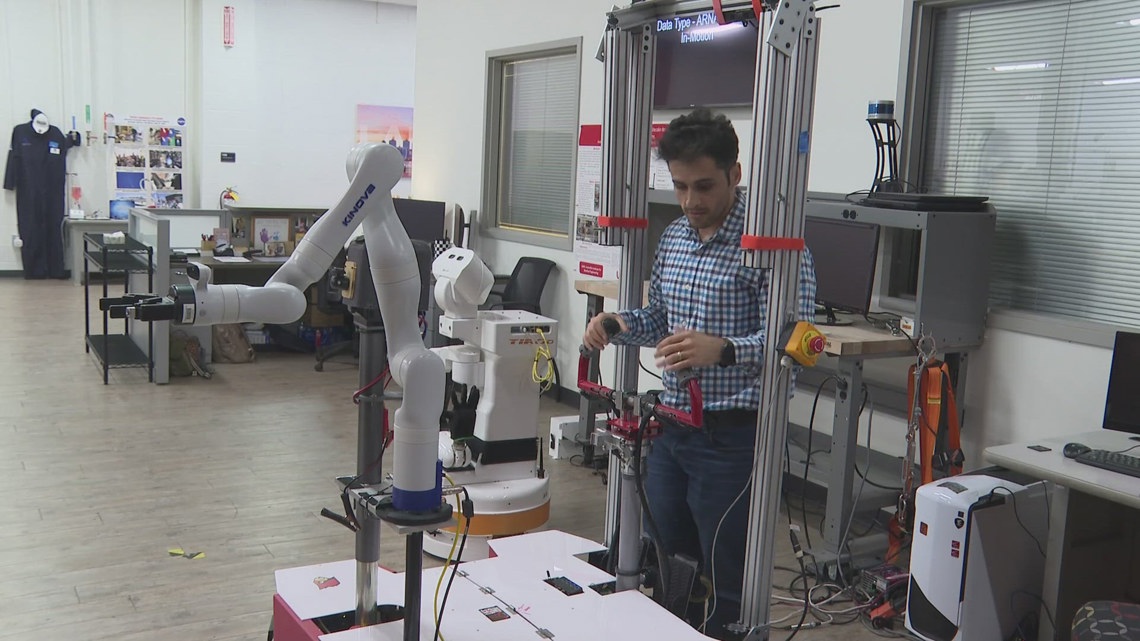

Emerging technologies are fundamentally reshaping manufacturing's global landscape. Artificial intelligence, blockchain, and advanced robotics are creating unprecedented opportunities for transparency, efficiency, and risk management within complex international production networks. These technological innovations enable more granular tracking, predictive maintenance, and real-time optimization of manufacturing processes. Companies leveraging these advanced tools can develop more agile, responsive, and resilient production ecosystems that transcend traditional geographical limitations.Geopolitical Considerations in Manufacturing Strategy

Geopolitical dynamics increasingly influence manufacturing strategies, with international tensions and trade policies creating complex operational environments. Manufacturers must develop nuanced, adaptive strategies that anticipate potential regulatory shifts and geopolitical disruptions. Strategic flexibility has become paramount, with forward-thinking organizations developing multi-regional production capabilities that can rapidly reconfigure in response to changing global conditions. This approach represents a sophisticated evolution beyond traditional, static manufacturing models.RELATED NEWS

Manufacturing

Manufacturing Momentum: Zetwerk Expands Footprint with Tamil Nadu Plant, Eyes Public Listing

2025-03-18 05:00:00

Manufacturing

Manufacturing Mirage: Why Trump's Nostalgia Can't Revive America's Industrial Heartland

2025-05-01 21:30:08

Manufacturing

Roche Doubles Down: $50B Bet on American Innovation Amid Global Trade Tensions

2025-04-22 05:56:00