Economic Alarm Bells: Job Market Tremors and Factory Slowdown Signal Potential Recession Ahead

Manufacturing

2025-04-01 16:07:10Content

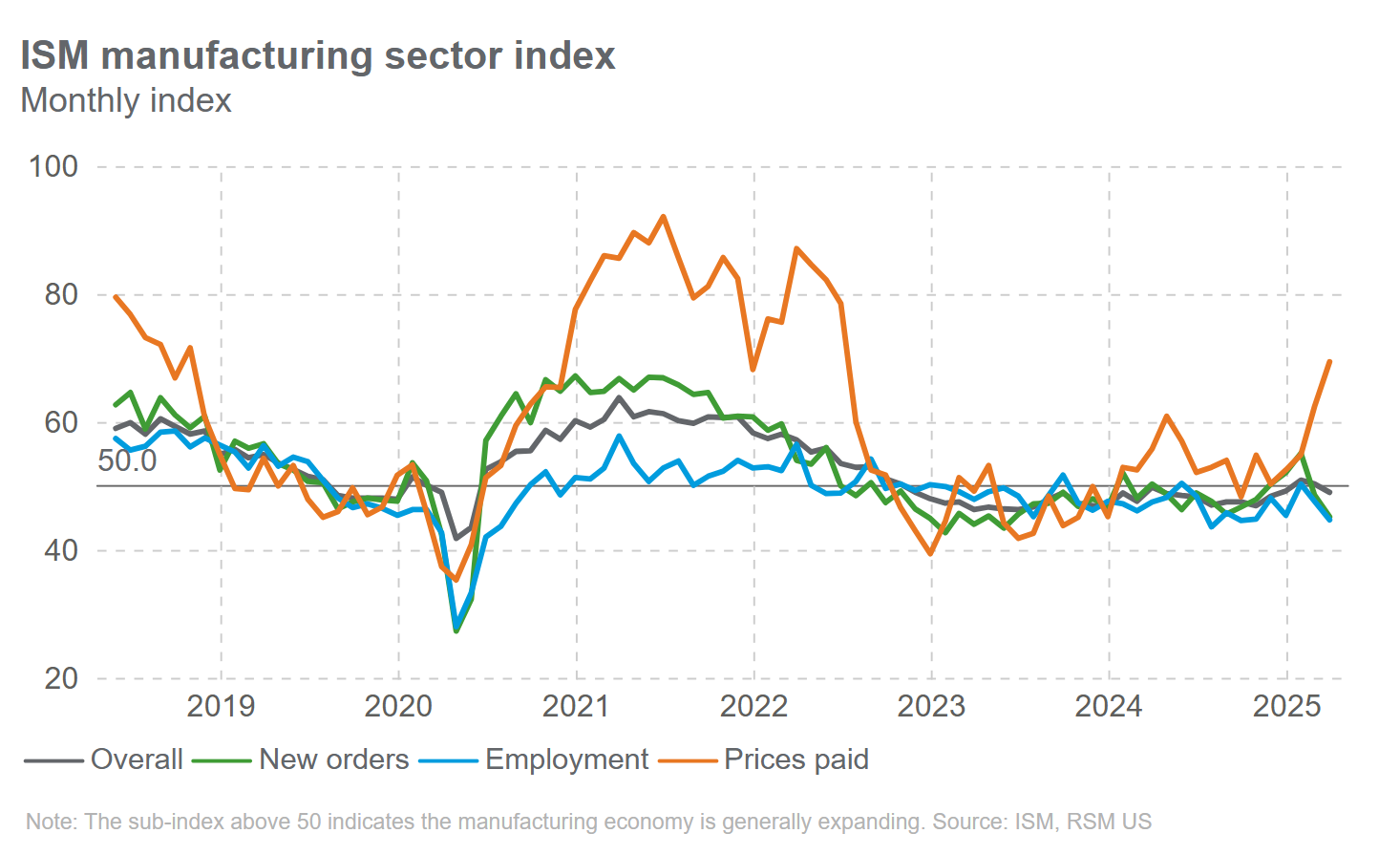

Manufacturing Sector Faces Renewed Challenges as Trade Tensions Weigh on Business Confidence

The manufacturing landscape continues to navigate turbulent waters, with recent data revealing a contraction in activity and business sentiment. After two months of modest growth, the sector has once again encountered headwinds, primarily driven by the looming specter of potential tariffs that are casting a shadow over order volumes and pricing strategies.

Businesses are increasingly cautious, with manufacturers closely monitoring the evolving trade environment and its potential impact on their operational strategies. The anticipated tariffs have prompted a pullback in new orders and created uncertainty that is rippling through supply chains and production planning.

This latest downturn underscores the fragile nature of manufacturing recovery and highlights the ongoing challenges faced by industries navigating complex global economic conditions. Companies are being forced to adapt quickly, reassessing their market approaches and seeking innovative ways to mitigate the potential economic pressures.

Manufacturing Sector Trembles: Tariff Tensions Trigger Economic Uncertainty

In the complex landscape of global economic dynamics, manufacturing industries find themselves navigating treacherous waters, buffeted by the unpredictable winds of international trade policies and geopolitical tensions. The intricate interplay of economic forces continues to challenge traditional manufacturing paradigms, creating a volatile environment that demands strategic adaptation and resilience.Unraveling the Economic Fabric: When Trade Policies Disrupt Industrial Momentum

The Tariff Tremor: Understanding Manufacturing's Fragile Ecosystem

The manufacturing sector stands at a critical crossroads, experiencing unprecedented challenges that extend far beyond simple economic fluctuations. Anticipated tariff implementations have created a ripple effect of uncertainty, fundamentally altering the strategic calculus for industrial decision-makers. Companies are now forced to recalibrate their operational strategies, reassessing supply chains, production capabilities, and long-term investment plans in response to the evolving global trade landscape. Manufacturers are encountering complex challenges that require nuanced approaches. The potential imposition of tariffs introduces significant complexity into procurement processes, pricing strategies, and competitive positioning. Organizations must develop sophisticated risk mitigation strategies that can adapt quickly to changing economic conditions, leveraging advanced analytics and predictive modeling to navigate these turbulent waters.Economic Sentiment and Operational Resilience

The current manufacturing environment reflects a profound transformation in industrial sentiment. Traditional metrics of economic performance are being challenged by unprecedented global disruptions, forcing companies to reimagine their operational frameworks. The contraction in manufacturing activity signals a deeper structural shift, highlighting the need for agile and adaptive business models. Economic indicators suggest a multifaceted challenge that extends beyond simple market fluctuations. Manufacturers are experiencing a complex interplay of factors, including geopolitical tensions, technological disruptions, and evolving regulatory landscapes. This requires a holistic approach to strategic planning, one that integrates technological innovation, workforce development, and sophisticated risk management techniques.Global Trade Dynamics and Strategic Recalibration

The manufacturing sector's current state represents a microcosm of broader global economic transformations. Anticipated tariffs are not merely economic instruments but sophisticated geopolitical tools that reshape international trade relationships. Companies must develop comprehensive strategies that transcend traditional reactive approaches, instead embracing proactive and anticipatory methodologies. Sophisticated manufacturers are increasingly recognizing the need for flexible, adaptive supply chain architectures. This involves developing robust contingency plans, diversifying sourcing strategies, and investing in technologies that enable rapid operational pivots. The ability to quickly reconfigure production capabilities has become a critical competitive advantage in an increasingly unpredictable global marketplace.Technological Innovation as a Competitive Imperative

In response to economic uncertainties, leading manufacturers are accelerating technological integration as a strategic imperative. Advanced technologies like artificial intelligence, machine learning, and predictive analytics are becoming essential tools for navigating complex economic landscapes. These technologies enable more sophisticated decision-making processes, allowing companies to anticipate and mitigate potential disruptions. The convergence of technological innovation and strategic adaptability represents the future of manufacturing. Organizations that can effectively leverage cutting-edge technologies while maintaining operational flexibility will be best positioned to thrive in an increasingly complex global economic environment. This requires a holistic approach that integrates technological capabilities with strategic vision and organizational agility.RELATED NEWS

Manufacturing

Manufacturing's Digital Revolution: Cloud MES Market Set to Explode to $24B, Tech Titans Battle for Supremacy

2025-03-13 11:43:00

Manufacturing

Inside Unilever's Chicago Powerhouse: Where Innovation Meets Manufacturing Grit

2025-03-19 12:32:31

Manufacturing

Driving the Future: GM and NVIDIA Forge AI Powerhouse for Next-Generation Vehicles

2025-03-19 17:35:22