Factory Floor Fears: Manufacturing Sector Shrinks as Trade Tensions Escalate

Manufacturing

2025-04-01 14:04:01Content

The U.S. manufacturing sector experienced a surprising downturn in March, breaking a two-month streak of growth. The unexpected contraction comes amid escalating tensions surrounding international trade and mounting concerns over potential tariffs on imported goods.

Simultaneously, factory-gate inflation surged to its highest point in nearly three years, signaling potential challenges for manufacturers and economists alike. This spike in prices reflects the complex economic landscape businesses are navigating in an increasingly uncertain global market.

The sudden shift in manufacturing performance highlights the delicate balance of economic factors influencing industrial production. Businesses are closely monitoring trade policies and market dynamics as they seek to maintain stability and competitiveness in a rapidly changing economic environment.

Analysts suggest that the combination of rising inflation and manufacturing contraction could be a warning sign of broader economic pressures facing the United States. The intricate interplay between trade tensions, production costs, and market demand continues to create uncertainty for industry leaders and policymakers.

Manufacturing Sector Trembles: Tariffs and Inflation Spark Economic Uncertainty

In the intricate landscape of American industrial production, a complex narrative is unfolding that reveals the delicate balance between economic resilience and emerging challenges. The manufacturing sector stands at a critical crossroads, where global economic tensions, trade policies, and inflationary pressures converge to create a nuanced and potentially transformative economic environment.Navigating Turbulent Economic Waters: A Deep Dive into Manufacturing Dynamics

The Contraction Conundrum: Unraveling Manufacturing's Complex Trajectory

The American manufacturing sector has entered a period of profound transformation, characterized by unexpected contractions and volatile market conditions. After experiencing two consecutive months of growth, the industry now faces a critical inflection point that demands careful analysis and strategic recalibration. Economic indicators suggest a multifaceted challenge emerging from intricate global trade dynamics and domestic economic pressures. Manufacturers are confronting unprecedented challenges that extend far beyond simple production metrics. The recent contraction represents more than a statistical anomaly; it signals a potential structural shift in industrial capabilities and economic adaptability. Sophisticated economic models indicate that this downturn might be symptomatic of broader macroeconomic trends affecting industrial output and strategic planning.Inflationary Pressures: The Silent Economic Disruptor

Inflation has emerged as a critical factor reshaping the manufacturing landscape, with factory gate prices reaching their highest levels in nearly three years. This surge represents more than a numerical increase; it reflects complex interactions between global supply chains, trade policies, and economic uncertainty. The escalating price environment creates a challenging ecosystem for manufacturers, who must simultaneously manage rising input costs, maintain competitive pricing, and preserve profit margins. Sophisticated economic strategies are becoming increasingly necessary to navigate this intricate economic terrain, requiring unprecedented levels of financial agility and strategic foresight.Tariff Tensions: Global Trade's Ripple Effect

The specter of tariffs looms large over the manufacturing sector, introducing additional layers of complexity to an already intricate economic environment. These trade barriers are not merely administrative mechanisms but powerful instruments that can fundamentally reshape industrial competitiveness and strategic positioning. Imported goods face increasing scrutiny and potential additional costs, creating a ripple effect that extends through entire supply chains. Manufacturers must now develop sophisticated risk mitigation strategies that account for potential trade disruptions, exploring alternative sourcing mechanisms and developing more resilient operational frameworks.Strategic Adaptation: The Path Forward

Successful navigation of this complex economic landscape will require unprecedented levels of strategic innovation and adaptive capacity. Manufacturers must develop holistic approaches that integrate technological innovation, flexible supply chain management, and proactive economic forecasting. The current economic moment demands a reimagining of traditional industrial strategies, emphasizing resilience, technological integration, and strategic flexibility. Those organizations capable of rapidly adapting to changing economic conditions will be best positioned to thrive in an increasingly unpredictable global marketplace.RELATED NEWS

Manufacturing

Bridging Gaps: How UT's Innovative Collaboration Could Solve America's Defense Manufacturing Crisis

2025-03-20 13:30:05

Manufacturing

STEM Sparks Fly: John Deere Transforms Classroom into Innovation Lab for Young Learners

2025-05-02 22:15:00

Manufacturing

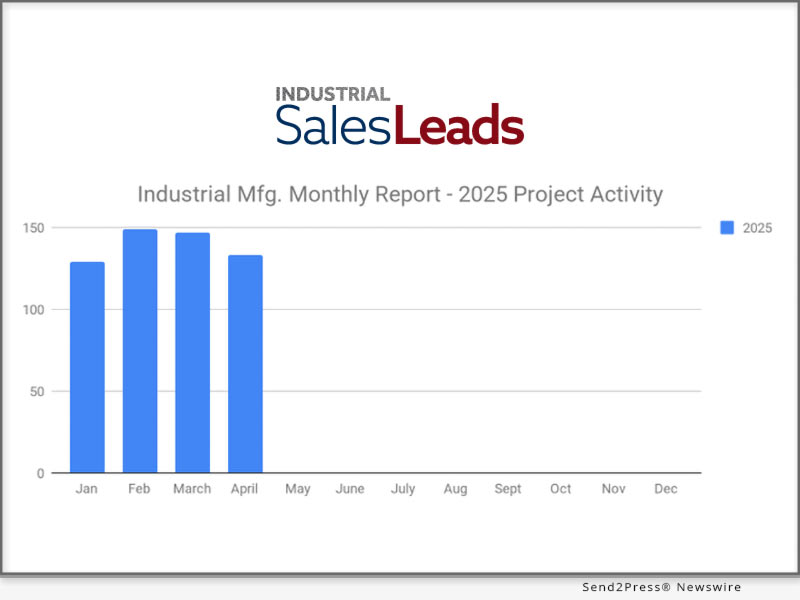

Manufacturing Boom: 133 Mega Projects Set to Revolutionize Industrial Landscape in 2025

2025-05-06 12:00:26