Silicon Valley's Industrial Revolution: AI Threatens to Outpace Human Workers in Manufacturing Resurgence

Manufacturing

2025-03-28 09:00:08Content

Donald Trump's ambitious plan to bring manufacturing jobs back to the United States might have an unexpected twist: instead of creating a massive employment surge, it could potentially trigger an automation revolution. As companies return to American soil, they're likely to invest in cutting-edge, highly automated factories that require fewer human workers than traditional manufacturing facilities.

The potential reshoring of manufacturing could paradoxically lead to a technological transformation, where state-of-the-art robotics and artificial intelligence replace traditional labor-intensive production methods. These next-generation factories would represent the pinnacle of industrial efficiency, leveraging advanced technologies to maximize productivity while minimizing human workforce requirements.

While the goal of bringing jobs back to America is noble, the economic reality suggests that these new manufacturing facilities might actually reduce overall employment, as automation becomes increasingly sophisticated and cost-effective. The future of American manufacturing might look more like a high-tech, robot-driven landscape than the job-creating engine many envision.

The Automation Revolution: How Trump's Manufacturing Push Could Reshape American Industry

In the complex landscape of modern manufacturing, a profound transformation is brewing beneath the surface of political rhetoric and economic promises. The potential return of manufacturing to American shores represents far more than a simple jobs narrative—it's a potential catalyst for a technological revolution that could fundamentally redefine industrial production.Reimagining Manufacturing in the Age of Technological Disruption

The Technological Paradigm Shift

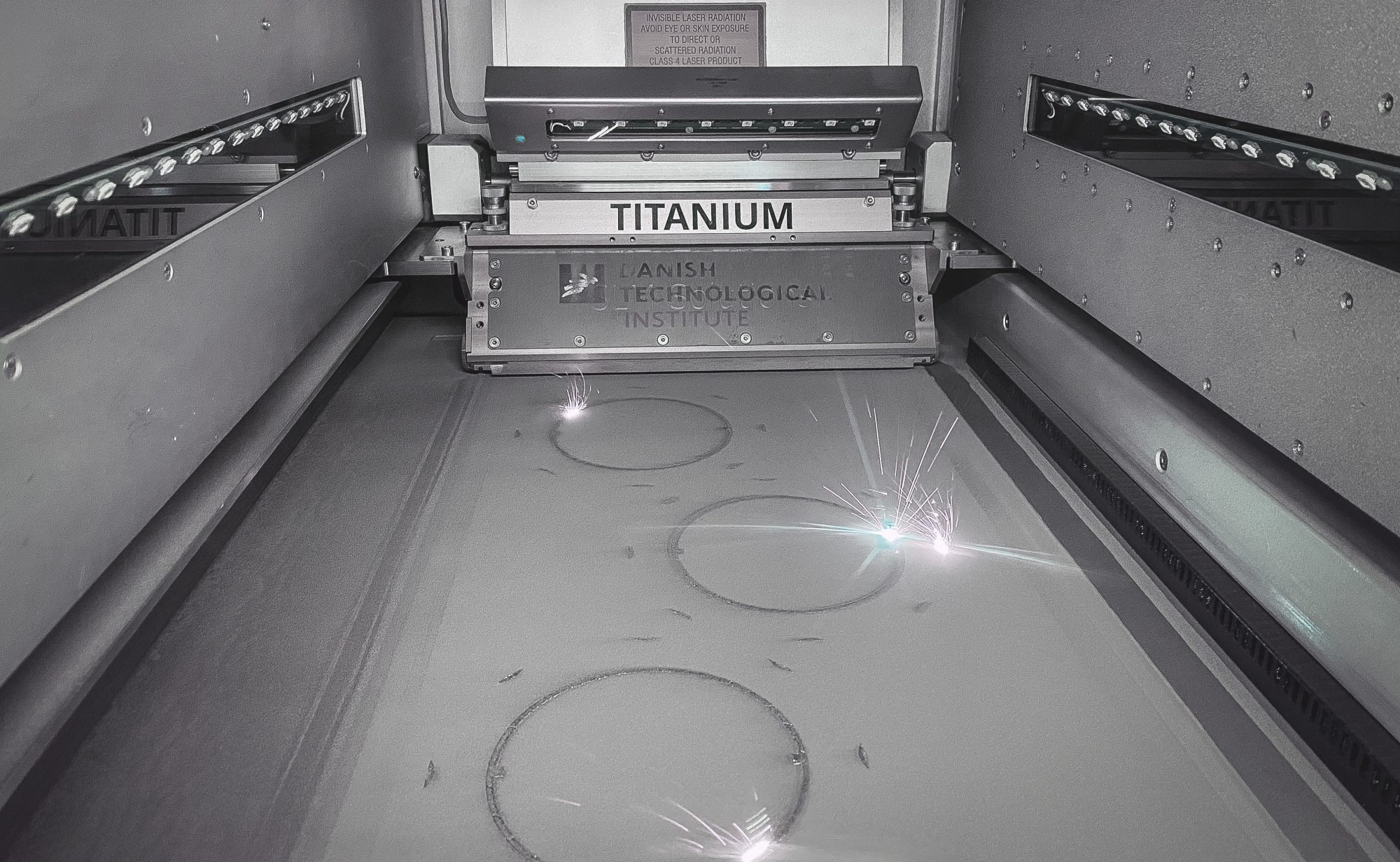

The resurgence of domestic manufacturing isn't merely about bringing jobs back—it's about creating the most advanced, technologically sophisticated production environments the world has ever seen. Modern factories are increasingly becoming temples of automation, where robotic systems and artificial intelligence replace traditional human labor with unprecedented efficiency and precision. Cutting-edge manufacturing facilities are now designed from the ground up with automation as their primary architectural and operational philosophy. Advanced robotics, machine learning algorithms, and integrated sensor networks transform production lines into intelligent, self-optimizing ecosystems that can adapt, learn, and improve in real-time.Economic Implications of Hyper-Automated Manufacturing

While political narratives often focus on job creation, the reality of modern manufacturing tells a dramatically different story. Each new factory represents not just a workplace, but a complex technological infrastructure that fundamentally challenges traditional employment models. Robotic systems can work continuously without fatigue, maintain consistent quality, and operate with a level of precision impossible for human workers. This means that while a factory might represent a significant investment, its long-term operational costs could be dramatically lower than traditional labor-intensive models.The Global Competitive Landscape

American manufacturers are not just competing domestically—they're engaging in a global technological arms race. Countries like Germany, Japan, and China are investing billions in advanced manufacturing technologies, creating production environments that blur the lines between traditional industrial processes and cutting-edge technological innovation. The potential return of manufacturing to the United States isn't just about reclaiming lost economic territory—it's about establishing a new paradigm of technological leadership. Each automated factory becomes a statement of technological prowess, demonstrating the nation's capacity for innovation and strategic industrial development.Workforce Transformation and Skills Evolution

The rise of hyper-automated manufacturing demands a radical reimagining of workforce skills and educational priorities. Workers will need to transition from manual laborers to technological managers, programmers, and system integrators. Technical education must evolve rapidly, creating curricula that prepare workers to interact with, maintain, and optimize complex automated systems. Community colleges, technical schools, and universities will play a crucial role in bridging the skills gap created by this technological revolution.Environmental and Efficiency Considerations

Automated manufacturing isn't just about economic efficiency—it also presents significant environmental opportunities. Precision robotics can minimize material waste, optimize energy consumption, and create production processes with dramatically reduced carbon footprints. The integration of Internet of Things (IoT) technologies and advanced analytics allows manufacturers to monitor and optimize every aspect of production, creating more sustainable and environmentally responsible industrial ecosystems.Navigating the Technological Transition

The path to a fully automated manufacturing landscape is complex and fraught with challenges. Policymakers, industry leaders, and educational institutions must collaborate to create supportive ecosystems that encourage technological innovation while managing potential social disruptions. Strategic investments in research and development, flexible regulatory frameworks, and comprehensive workforce retraining programs will be essential in transforming the potential of automated manufacturing into tangible economic and social benefits.RELATED NEWS

Manufacturing

Chip Giant's Big Move: Amundi Doubles Down on Taiwan Semiconductor with Massive Stock Purchase

2025-03-09 10:43:35

Manufacturing

Breaking: McCann Pioneers Advanced Manufacturing Tech Program with Inaugural Adult Cohort

2025-05-03 06:55:00

Manufacturing

Bending Metal, Building Dreams: How One Family Turned Sheet Metal into a Generational Success Story

2025-05-05 20:18:40