3D Printing: The Secret Weapon Against Costly Trade Barriers

Manufacturing

2025-03-24 00:00:00Content

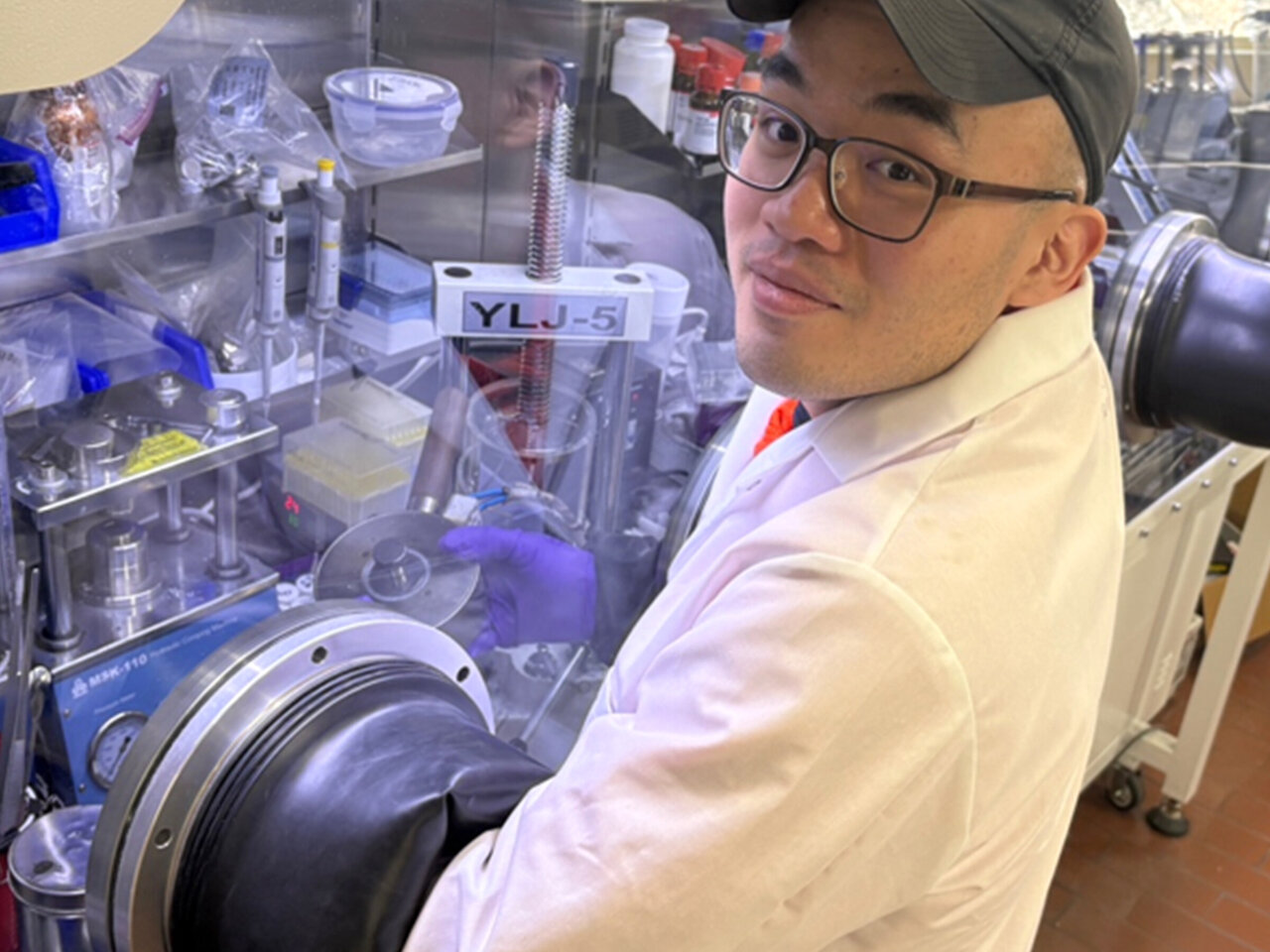

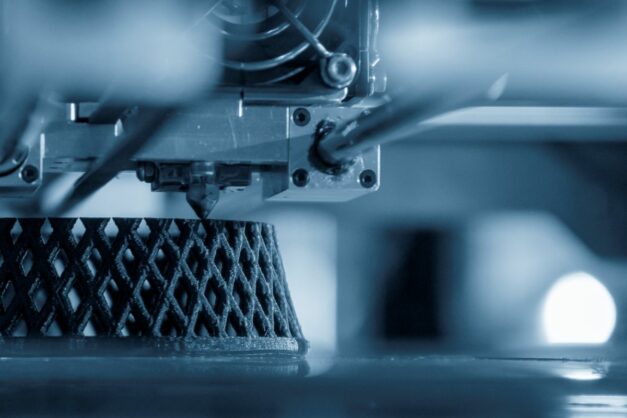

Revolutionizing Business Operations: The Power of Additive Manufacturing and Advanced Technology

In today's rapidly evolving business landscape, innovative technologies are transforming how companies approach operational efficiency and strategic decision-making. Additive manufacturing and cutting-edge technological solutions are emerging as game-changing resources that empower leaders to reimagine their business processes and leap into the future of industrial innovation.

By leveraging advanced manufacturing techniques like 3D printing and sophisticated technological platforms, organizations can unlock unprecedented levels of flexibility, precision, and cost-effectiveness. These transformative tools enable businesses to streamline production, customize solutions, and respond with agility to dynamic market demands.

Modern decision-makers who embrace these technologies gain a competitive edge, breaking free from traditional manufacturing constraints and positioning themselves at the forefront of industrial innovation. From rapid prototyping to complex component creation, additive manufacturing provides businesses with the versatility to adapt, create, and excel in an increasingly digital world.

The integration of advanced technology is no longer a luxury but a strategic imperative for companies seeking to optimize their operations, reduce waste, and drive sustainable growth. By investing in these innovative solutions, businesses can transform their operational models and chart a path toward a more efficient, responsive, and technologically advanced future.

Revolutionizing Industry: The Transformative Power of Advanced Manufacturing Technologies

In an era of unprecedented technological innovation, businesses are standing at the precipice of a manufacturing revolution that promises to reshape entire industries, drive unprecedented efficiency, and unlock potential that was once considered impossible. The convergence of cutting-edge technologies is creating a landscape where traditional manufacturing boundaries are rapidly dissolving, giving rise to more adaptive, intelligent, and responsive production methodologies.Unleash Your Business Potential: The Future of Manufacturing is Here!

The Technological Metamorphosis of Modern Manufacturing

The manufacturing sector is experiencing a profound transformation driven by breakthrough technologies that are redefining how companies conceptualize, design, and produce goods. Advanced manufacturing techniques are no longer just incremental improvements but represent fundamental shifts in industrial paradigms. These technologies enable organizations to transcend traditional limitations, creating more agile, responsive, and innovative production ecosystems. Sophisticated computational systems and intelligent design platforms now allow engineers and designers to simulate complex manufacturing scenarios with unprecedented accuracy. Machine learning algorithms can predict potential production challenges, optimize resource allocation, and dramatically reduce waste and inefficiencies. This technological symbiosis represents a quantum leap in manufacturing capabilities.Additive Manufacturing: Beyond Traditional Production Boundaries

Three-dimensional printing technologies have emerged as a revolutionary force, fundamentally challenging conventional manufacturing approaches. Unlike traditional subtractive methods that remove material to create components, additive manufacturing builds objects layer by layer, offering remarkable design flexibility and material efficiency. Companies across diverse sectors—from aerospace and automotive to healthcare and consumer electronics—are discovering the transformative potential of these technologies. Complex geometries that were previously impossible or prohibitively expensive can now be produced with remarkable precision. This capability enables engineers to create lightweight, structurally optimized components that enhance performance while reducing material consumption.Digital Twin Technologies: Bridging Physical and Virtual Realms

Digital twin technologies represent another groundbreaking advancement in modern manufacturing. By creating virtual replicas of physical systems, organizations can simulate, predict, and optimize performance in real-time. These sophisticated digital models allow engineers to test scenarios, predict maintenance requirements, and identify potential issues before they manifest in physical production environments. The integration of Internet of Things (IoT) sensors and advanced analytics transforms these digital twins into powerful predictive tools. Manufacturers can now monitor equipment performance, anticipate potential failures, and implement proactive maintenance strategies that minimize downtime and maximize operational efficiency.Sustainable Manufacturing: Technology as an Environmental Catalyst

Advanced manufacturing technologies are not just about improving productivity; they're increasingly becoming critical tools in addressing global sustainability challenges. Precision manufacturing techniques enable more efficient material usage, reduced waste generation, and lower carbon footprints. Innovative recycling technologies and circular economy principles are being integrated directly into manufacturing processes. Companies can now design products with end-of-life recyclability in mind, creating closed-loop systems that minimize environmental impact while maintaining high-performance standards.The Human-Technology Symbiosis

Contrary to fears about technological displacement, advanced manufacturing technologies are creating new opportunities for human creativity and skill development. Workers are increasingly becoming technology orchestrators, leveraging sophisticated tools to solve complex challenges and drive innovation. Training programs and educational initiatives are emerging to equip professionals with the skills needed to thrive in this new technological landscape. The future of manufacturing is not about replacing human workers but empowering them with increasingly intelligent and responsive technological tools.Strategic Implementation: Navigating the Technological Frontier

Successfully integrating advanced manufacturing technologies requires a holistic, strategic approach. Organizations must develop comprehensive transformation roadmaps that align technological investments with broader business objectives. This involves not just acquiring new technologies but cultivating a culture of continuous learning and technological adaptability. Leadership plays a crucial role in driving this transformation. Executives must foster environments that encourage experimentation, tolerate calculated risks, and view technological innovation as a core strategic imperative rather than a peripheral consideration.RELATED NEWS

Manufacturing

Battery Breakthrough: How Volklec is Electrifying the UK's Energy Independence

2025-02-27 14:25:11

Manufacturing

Manufacturing's Pulse: What the ISM Report Reveals About March's Industrial Landscape

2025-04-01 19:46:31