Forging the Future: How Tech Innovations Are Reshaping Global Manufacturing

Manufacturing

2025-03-20 08:30:31Content

Pioneering Innovation: Mace's Transformative Journey in Technology and Manufacturing

In the rapidly shifting landscape of technology and manufacturing, Mace stands at the forefront of innovation, driving meaningful change through a forward-thinking and inclusive approach. Our commitment goes beyond traditional boundaries, embracing cutting-edge solutions that challenge conventional thinking and create new possibilities.

At the heart of Mace's philosophy is a deep understanding that true progress emerges from diversity of thought and collaborative excellence. We recognize that the most groundbreaking innovations arise when talented individuals from varied backgrounds come together, bringing unique perspectives and creative insights to complex challenges.

Our approach seamlessly blends technological expertise with human-centered design, ensuring that every solution we develop not only meets technical specifications but also addresses real-world needs. By fostering an environment of continuous learning and adaptive strategy, we transform potential obstacles into opportunities for growth and breakthrough innovation.

From advanced manufacturing techniques to transformative technological solutions, Mace is committed to pushing the boundaries of what's possible. We don't just adapt to change—we actively shape the future, creating pathways that inspire progress and unlock unprecedented potential in technology and manufacturing.

Revolutionizing Technology and Manufacturing: A Comprehensive Exploration of Innovation and Transformation

In the rapidly evolving landscape of global industry, technology and manufacturing stand at the forefront of unprecedented change, driving economic growth, technological advancement, and transformative solutions that reshape how businesses and societies operate in the 21st century.Unleashing Potential: Where Innovation Meets Industrial Excellence

The Digital Revolution in Manufacturing Ecosystems

The contemporary manufacturing landscape has undergone a profound metamorphosis, transcending traditional production paradigms. Advanced technologies like artificial intelligence, machine learning, and Internet of Things (IoT) are fundamentally restructuring industrial processes, enabling unprecedented levels of efficiency, precision, and adaptability. Manufacturers are now leveraging sophisticated digital twin technologies that create virtual replicas of physical systems, allowing real-time monitoring, predictive maintenance, and optimization of complex production workflows. These technological interventions dramatically reduce operational costs, minimize downtime, and enhance overall system performance.Sustainable Technology and Eco-Friendly Manufacturing Strategies

Modern manufacturing is increasingly characterized by a commitment to environmental sustainability. Companies are integrating green technologies, circular economy principles, and renewable energy solutions into their core operational strategies. This holistic approach not only reduces carbon footprints but also creates long-term economic value. Innovative materials science is driving the development of biodegradable components, advanced recycling techniques, and energy-efficient production methodologies. By reimagining manufacturing through an ecological lens, industries are demonstrating that technological progress and environmental stewardship can coexist harmoniously.Human-Centric Technology Integration

The intersection of human expertise and technological capabilities represents a critical frontier in modern manufacturing. Collaborative robotics, augmented reality training systems, and adaptive workforce development programs are transforming traditional labor dynamics. Organizations are investing in comprehensive upskilling initiatives, ensuring that human workers can effectively collaborate with advanced technological systems. This approach recognizes that technology should complement human capabilities, not replace them, creating more engaging, productive, and innovative work environments.Global Supply Chain Resilience and Technological Adaptation

Recent global disruptions have underscored the critical importance of technological flexibility in supply chain management. Advanced predictive analytics, blockchain technologies, and real-time tracking systems are enabling businesses to build more robust, transparent, and responsive global networks. Manufacturers are developing sophisticated risk mitigation strategies, utilizing machine learning algorithms to anticipate potential disruptions and create adaptive, decentralized supply chain architectures. These technological interventions provide unprecedented levels of operational agility and strategic responsiveness.Emerging Technologies Shaping Future Manufacturing Landscapes

Cutting-edge technologies like quantum computing, advanced robotics, and nanotechnology are poised to revolutionize manufacturing capabilities. These innovations promise unprecedented precision, miniaturization, and computational power, opening new frontiers of technological possibility. Research and development investments are accelerating, with interdisciplinary collaborations between academic institutions, technology firms, and manufacturing enterprises driving rapid technological evolution. The future of manufacturing will be defined by continuous innovation, adaptability, and a relentless pursuit of technological excellence.RELATED NEWS

Manufacturing

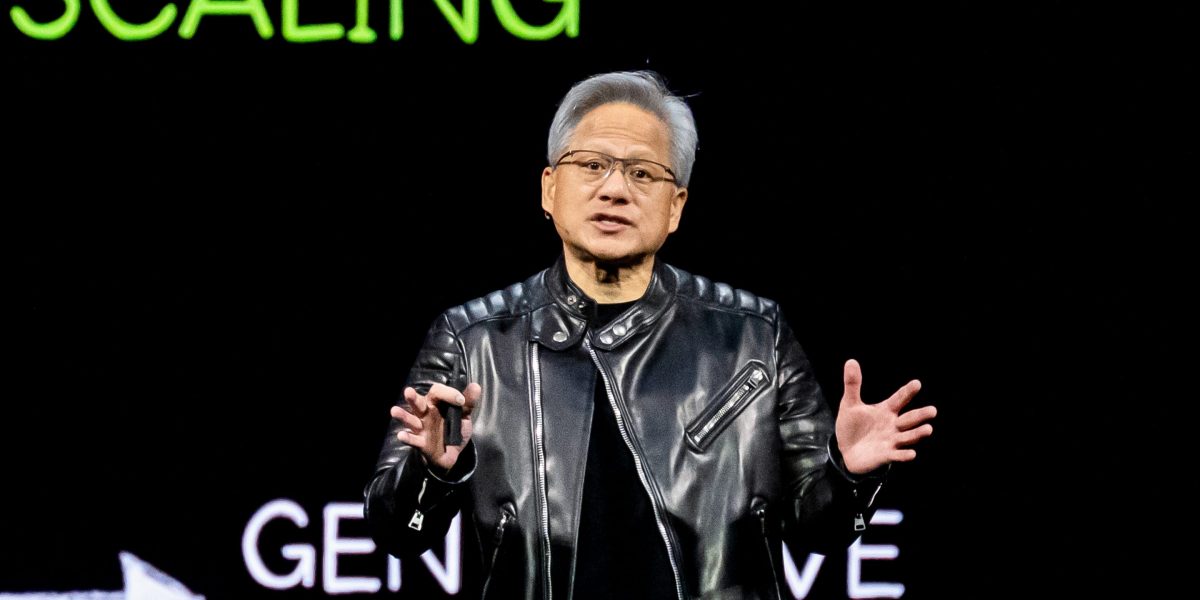

Digital Doppelgängers: Nvidia's Bold Vision for Corporate Survival in the AI Era

2025-03-20 08:42:00

Manufacturing

Breaking: Revolutionary Contraceptive PHEXXI Slashes Prices, Opens Doors to Affordable Family Planning

2025-03-26 12:47:00

Manufacturing

Tech Titan's Urban Revival: Apple Transforms Detroit with $500B Skills Academy

2025-02-24 19:08:00