Monoclonal Antibody Manufacturing: The Inside Scoop on Winning Strategies

Manufacturing

2025-03-19 00:00:00Content

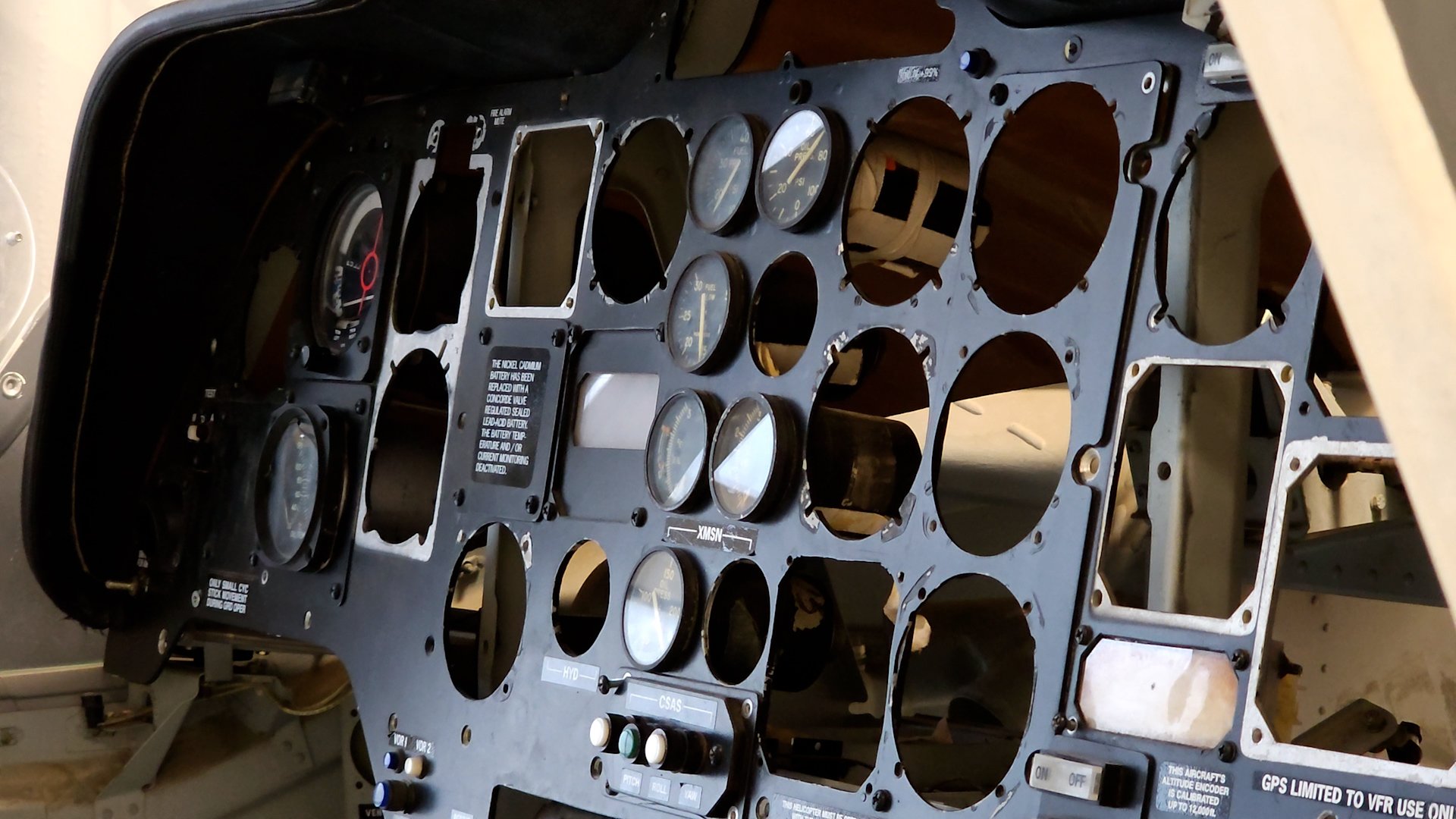

Navigating the Complex Landscape of Monoclonal Antibody Manufacturing: Scaling Strategies Unveiled

In the rapidly evolving world of biopharmaceutical production, manufacturers are increasingly focused on optimizing monoclonal antibody (mAb) manufacturing processes. As industry challenges around cost and supply chain resilience intensify, companies are exploring strategic approaches to scale production effectively.

Three primary scaling strategies have emerged as critical pathways for mAb manufacturing, each offering unique advantages and potential limitations. These approaches represent sophisticated solutions to the complex challenge of meeting growing global demand while maintaining production efficiency and economic viability.

By carefully evaluating the nuanced characteristics of each scaling strategy, biotechnology and pharmaceutical companies can develop more robust and adaptable manufacturing frameworks that balance technological innovation with practical operational considerations.

The ongoing quest for optimal mAb production continues to drive technological advancements and strategic thinking in this dynamic sector, promising more sophisticated and responsive manufacturing capabilities in the years ahead.

Revolutionizing Monoclonal Antibody Manufacturing: Breakthrough Scaling Strategies Unveiled

In the rapidly evolving landscape of biotechnology, monoclonal antibody (mAb) production stands at a critical crossroads. Manufacturers are increasingly challenged to balance complex production requirements with economic feasibility, driving innovative approaches that could reshape the entire pharmaceutical manufacturing ecosystem.Transforming Biotech Manufacturing: The Future of Monoclonal Antibody Production

The Economic Imperative of Advanced Manufacturing Techniques

The pharmaceutical industry is experiencing a profound transformation in monoclonal antibody production methodologies. Traditional manufacturing approaches are being systematically dismantled and reconstructed to address escalating economic pressures and technological constraints. Biotechnology firms are now compelled to explore sophisticated scaling strategies that transcend conventional production paradigms. Emerging technologies are fundamentally reimagining how monoclonal antibodies are developed, with cutting-edge research focusing on optimizing production efficiency while maintaining rigorous quality standards. Manufacturers must navigate a complex landscape of technological innovation, regulatory compliance, and economic sustainability.Comprehensive Analysis of Scaling Methodologies

Modern mAb manufacturing demands a multifaceted approach that integrates advanced biotechnological principles with strategic economic considerations. Researchers are developing nuanced strategies that address the intricate challenges of large-scale antibody production, exploring innovative techniques that maximize yield while minimizing production costs. The complexity of scaling monoclonal antibody production requires a holistic understanding of biological systems, engineering principles, and economic dynamics. Manufacturers must develop adaptive strategies that can rapidly respond to changing market demands and technological advancements.Technological Innovations Driving Manufacturing Transformation

Breakthrough technologies are revolutionizing the monoclonal antibody production landscape. Sophisticated bioengineering techniques are enabling unprecedented levels of precision and efficiency, allowing manufacturers to overcome traditional limitations in scaling production. Cutting-edge computational modeling and artificial intelligence are playing increasingly critical roles in optimizing production processes. These advanced technologies enable more accurate predictions of cellular behavior, potential bottlenecks, and production efficiency, ultimately driving more sophisticated manufacturing strategies.Navigating Regulatory and Economic Challenges

The monoclonal antibody manufacturing sector confronts complex regulatory environments that demand exceptional adaptability. Manufacturers must develop robust strategies that not only meet stringent regulatory requirements but also maintain economic viability in an increasingly competitive global market. Economic considerations are paramount in determining the success of mAb production strategies. Companies must carefully balance technological investment, production costs, and potential market returns, creating sophisticated economic models that support sustainable growth and innovation.Future Perspectives in Monoclonal Antibody Production

The future of monoclonal antibody manufacturing represents a convergence of biotechnology, engineering, and economic strategy. Emerging technologies promise to unlock unprecedented capabilities in production efficiency, quality control, and scalability. Interdisciplinary collaboration will be crucial in driving future innovations. Researchers, biotechnologists, engineers, and economic strategists must work together to develop comprehensive approaches that address the multifaceted challenges of mAb production.RELATED NEWS

Manufacturing

Powering American Industry: GE Aerospace Pumps $1B into Domestic Manufacturing Boom

2025-03-18 10:27:23

Manufacturing

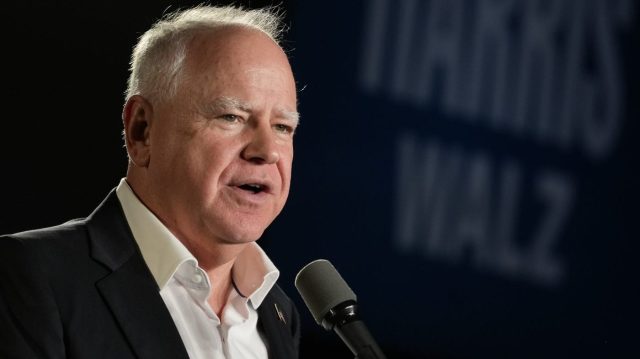

Manufacturing Meltdown: Walz Agrees with Trump's Critique, Rejects Tariff Remedy

2025-04-06 15:42:13

Manufacturing

Tariff Triumph: How Trump's Trade War Sparked a Toy Manufacturing Renaissance in America

2025-03-25 19:00:32