The AI Revolution: How Machine Learning Is Transforming Additive Manufacturing

Manufacturing

2025-03-18 09:27:39Content

The United Kingdom is pioneering a groundbreaking approach to sustainable manufacturing by seamlessly integrating advanced manufacturing (AM) technologies with artificial intelligence (AI), creating a powerful pathway towards achieving ambitious Net Zero environmental goals. This innovative strategy represents a transformative leap in industrial sustainability, where cutting-edge technological solutions are converging to reshape traditional manufacturing paradigms.

By leveraging the synergistic potential of additive manufacturing and intelligent AI systems, UK industries are developing more efficient, resource-conscious production methods. These technologies enable precise material usage, reduced waste, and enhanced product lifecycle management, which are critical components in the global fight against climate change.

The convergence of AM and AI is not just a technological advancement but a strategic approach to reimagining industrial processes. Manufacturers can now optimize design, predict maintenance requirements, and create more sustainable production models that significantly reduce carbon footprints. This holistic approach demonstrates the UK's commitment to leading global innovation in sustainable manufacturing.

As industries increasingly recognize the importance of circular economy principles, these integrated technologies offer a compelling solution for creating more resilient, adaptable, and environmentally responsible manufacturing ecosystems. The UK's proactive stance positions the nation at the forefront of global sustainable industrial transformation.

Revolutionizing Manufacturing: How AI and Additive Technologies Are Reshaping the UK's Sustainable Industrial Landscape

In the rapidly evolving world of industrial innovation, the United Kingdom stands at the forefront of a transformative technological revolution that promises to redefine manufacturing paradigms. As global industries grapple with unprecedented challenges of sustainability, efficiency, and environmental responsibility, British innovators are pioneering groundbreaking approaches that seamlessly integrate artificial intelligence and advanced manufacturing techniques.Powering the Future: Breakthrough Technologies Driving Industrial Transformation

The Convergence of Artificial Intelligence and Additive Manufacturing

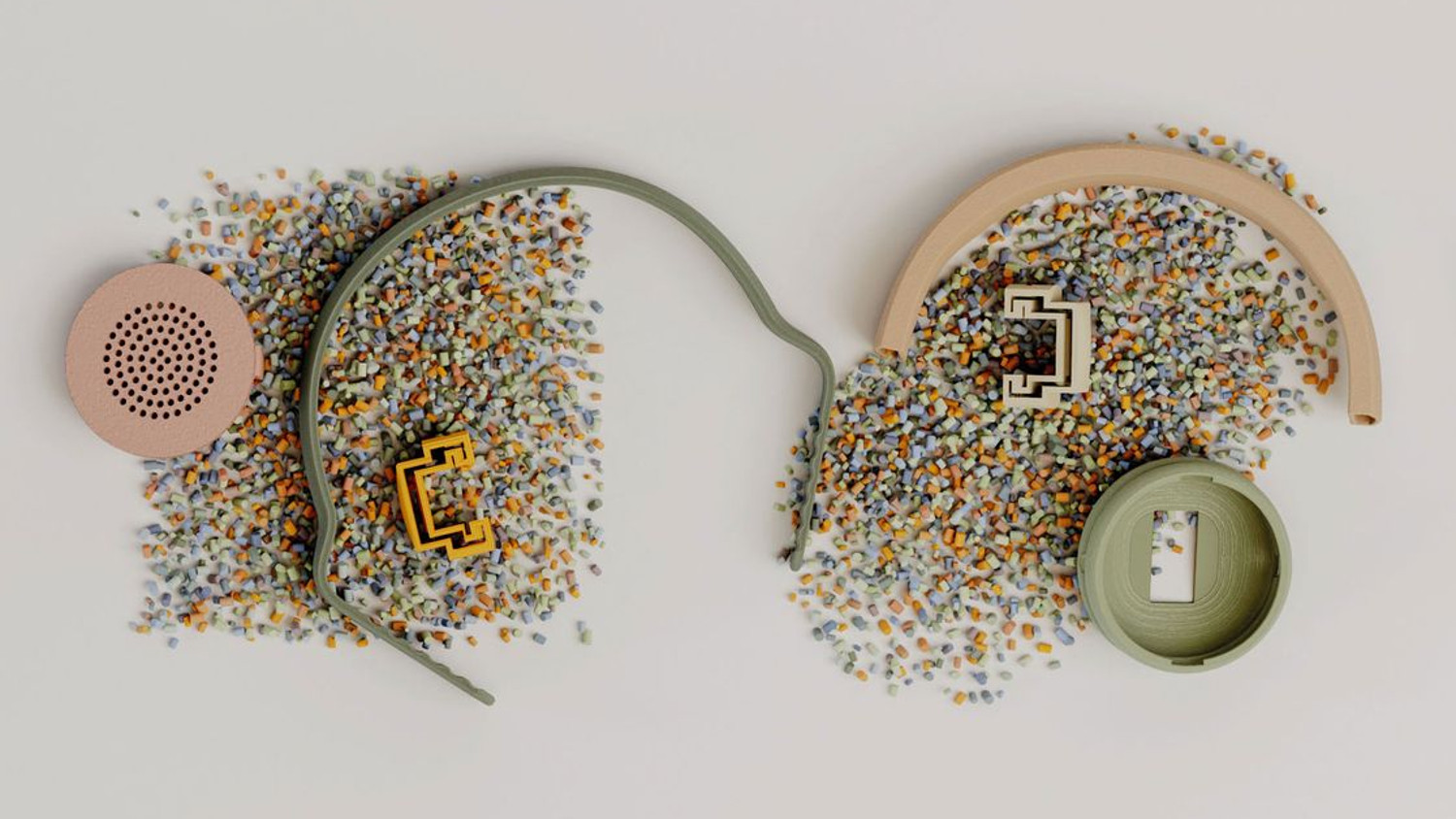

The symbiotic relationship between artificial intelligence and additive manufacturing represents a quantum leap in industrial capabilities. By leveraging sophisticated machine learning algorithms, manufacturers can now optimize design processes, predict material behaviors, and create intricate structures with unprecedented precision. This technological synergy enables engineers to develop complex geometries that were previously impossible, reducing material waste and enhancing structural integrity. Advanced neural networks analyze vast datasets, providing real-time insights into manufacturing parameters, allowing for dynamic adjustments during production. These intelligent systems can predict potential failures, recommend design modifications, and streamline entire production workflows with remarkable accuracy.Circular Manufacturing: A Sustainable Industrial Paradigm

Circular manufacturing emerges as a critical strategy for addressing environmental challenges in industrial production. Unlike traditional linear manufacturing models, circular approaches focus on regenerative design, material recycling, and minimizing ecological footprints. The United Kingdom has positioned itself as a global leader in this transformative approach, integrating cutting-edge technologies to create closed-loop manufacturing ecosystems. Additive manufacturing plays a pivotal role in this transition, enabling precise material usage, facilitating component repair and remanufacturing, and supporting the development of more sustainable production methodologies. By utilizing advanced 3D printing techniques, manufacturers can significantly reduce raw material consumption and energy expenditure.Net Zero Ambitions: Technology as a Catalyst for Environmental Progress

The United Kingdom's commitment to achieving Net Zero emissions by 2050 necessitates radical technological interventions across industrial sectors. Artificial intelligence and additive manufacturing emerge as critical enablers in this ambitious environmental strategy, providing sophisticated tools for emissions reduction and sustainable innovation. Intelligent systems can optimize energy consumption, predict maintenance requirements, and design more efficient manufacturing processes. By analyzing complex datasets, these technologies help industries identify and mitigate carbon-intensive practices, driving meaningful environmental transformation.Economic and Technological Implications

The integration of AI and additive manufacturing represents more than a technological advancement; it signifies a fundamental restructuring of industrial capabilities. British companies are developing robust ecosystems that attract global talent, foster innovation, and create high-value economic opportunities. Emerging startups and established industrial players are collaborating to push technological boundaries, developing scalable solutions that can be deployed across diverse manufacturing domains. This collaborative approach ensures that technological innovations translate into tangible economic and environmental benefits.Global Competitiveness and Future Outlook

As international markets become increasingly competitive, the United Kingdom's strategic investment in advanced manufacturing technologies positions the nation as a global innovation hub. By embracing artificial intelligence and additive manufacturing, British industries are not merely adapting to change but actively shaping the future of industrial production. The ongoing technological revolution promises unprecedented opportunities for sustainable development, economic growth, and environmental stewardship. As these transformative technologies continue to evolve, they will undoubtedly play a crucial role in addressing global challenges and creating more resilient, efficient industrial systems.RELATED NEWS

Manufacturing

Breaking: Major Manufacturer Lands in Fayetteville, Sparking Economic Boom

2025-03-20 09:07:52

Manufacturing

Tariff Triumph: How One GOP Congresswoman's District Sparked a $19M Manufacturing Renaissance

2025-04-22 14:00:09

Manufacturing

Trade Tensions Rise: Industry Chiefs Sound Alarm on Trump's Economic Roadmap

2025-03-17 16:45:22