No Humans Needed: Inside the Silent Revolution of Dark Factories Transforming Global Manufacturing

Manufacturing

2025-03-17 04:00:05Content

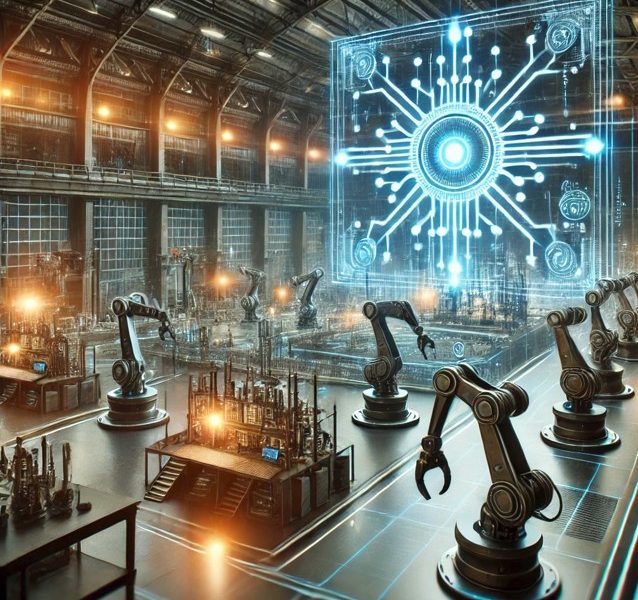

Imagine a factory where silence reigns supreme—no bustling workers, no flickering fluorescent lights, just the rhythmic hum of machines operating in perfect synchronization. Welcome to the world of dark factories, where artificial intelligence has transformed manufacturing into a seamless, human-free experience.

These cutting-edge facilities represent more than just a technological marvel; they're a glimpse into the future of production. Fully automated and driven by sophisticated AI systems, dark factories operate around the clock with unprecedented precision and efficiency. Robots and intelligent machines work tirelessly, producing goods at speeds and levels of consistency that human workers could never achieve.

While the promise of faster production and dramatically reduced operational costs is tantalizing, dark factories also spark profound questions about the future of work, human employment, and the evolving relationship between technology and labor. As these automated environments become increasingly sophisticated, they challenge our traditional understanding of manufacturing and workforce dynamics.

The rise of dark factories isn't just a technological trend—it's a fundamental reimagining of how we create, produce, and think about industrial processes in the 21st century.

Silent Factories: The Rise of Autonomous Manufacturing in the AI Era

In the rapidly evolving landscape of industrial innovation, a revolutionary transformation is quietly reshaping the manufacturing sector. Technological advancements are pushing the boundaries of production, creating environments where human presence is becoming increasingly optional, and artificial intelligence drives unprecedented levels of efficiency and productivity.Revolutionizing Production: When Machines Become the Workforce

The Technological Paradigm Shift

The emergence of dark factories represents a profound technological disruption that challenges traditional manufacturing paradigms. These fully automated facilities leverage cutting-edge artificial intelligence and robotics to create production environments that operate with minimal human intervention. Advanced sensor networks, machine learning algorithms, and sophisticated robotic systems collaborate seamlessly, transforming manufacturing from a human-centric process to an autonomous ecosystem. Complex machine learning models continuously optimize production workflows, analyzing real-time data streams to make instantaneous decisions about resource allocation, quality control, and operational efficiency. Unlike traditional manufacturing settings, these intelligent systems can predict maintenance requirements, self-diagnose potential issues, and dynamically adjust production parameters without human oversight.Economic and Operational Implications

The economic potential of dark factories extends far beyond simple cost reduction. By eliminating human labor constraints, these facilities can operate continuously, dramatically increasing production capacity and reducing operational downtime. Precision-engineered robotic systems maintain consistent quality standards, minimizing human error and ensuring product uniformity at scales previously unimaginable. Moreover, these autonomous manufacturing environments significantly reduce labor-related expenses, including wages, training, healthcare, and workplace safety infrastructure. Companies can redirect substantial financial resources toward technological innovation, research and development, and strategic growth initiatives.Technological Infrastructure and Requirements

Implementing a dark factory demands sophisticated technological infrastructure. High-bandwidth network connections, advanced edge computing systems, robust cybersecurity protocols, and intricate sensor networks form the foundational architecture. Machine learning algorithms must be meticulously trained to handle complex manufacturing processes, requiring substantial computational power and extensive datasets. Artificial intelligence models continuously learn and adapt, analyzing production data to optimize workflows, predict potential disruptions, and autonomously make strategic operational decisions. These systems represent a convergence of robotics, machine learning, Internet of Things (IoT) technologies, and advanced computational methodologies.Societal and Employment Challenges

The rise of dark factories introduces complex socioeconomic challenges. As automation replaces traditional manufacturing roles, entire workforce segments face potential displacement. This technological transition necessitates comprehensive workforce retraining programs, educational reforms, and innovative social support mechanisms. Governments and industries must collaborate to develop adaptive strategies that balance technological advancement with human economic sustainability. This might involve creating new job categories focused on AI system management, robotics maintenance, and technological innovation.Environmental and Sustainability Considerations

Dark factories offer significant environmental benefits by optimizing resource utilization and reducing waste. Precise robotic systems consume energy more efficiently, minimize material wastage, and enable more sustainable production methodologies. Advanced AI algorithms can continuously monitor and optimize energy consumption, contributing to broader environmental conservation efforts. By eliminating human physical limitations, these facilities can implement more complex and energy-efficient manufacturing processes, potentially revolutionizing industrial sustainability practices.Future Outlook and Potential Developments

The trajectory of dark factories suggests an increasingly autonomous manufacturing landscape. Future developments may include more sophisticated AI systems capable of handling increasingly complex production processes, enhanced machine learning models with superior predictive capabilities, and more seamlessly integrated robotic technologies. As technological capabilities expand, we can anticipate manufacturing environments that are not just automated but genuinely intelligent—capable of complex decision-making, self-optimization, and adaptive problem-solving.RELATED NEWS

Manufacturing

Beyond Machinery: How Human Skills Are Reshaping the Plastics Industry

2025-04-07 00:00:00

Manufacturing

Pharma Giant Chiesi Pumps €430M into Italian Manufacturing Powerhouse

2025-03-27 14:47:27

Manufacturing

Lake Superior College Unveils Cutting-Edge 'T Building': A Game-Changer in Integrated Manufacturing Education

2025-03-07 00:17:50