Aerospace 3D Printing Revolution: How Cutting-Edge Manufacturers Are Reshaping the Future of Flight by 2032

Manufacturing

2025-03-16 05:57:42Content

Aerospace Additive Manufacturing Market: Soaring to New Heights of Innovation

The aerospace industry is on the brink of a transformative revolution, with additive manufacturing emerging as a game-changing technology. According to Market Statistix, the Aerospace Additive Manufacturing Market is poised for remarkable growth, projecting substantial revenue expansion and technological advancements throughout the analysis period from 2024 to 2032.

With 2023 serving as the foundational base year, the market is expected to witness unprecedented development. This cutting-edge manufacturing approach is set to redefine aerospace design, production, and performance, offering unprecedented opportunities for industry stakeholders.

Key Highlights:

- Significant market revenue growth anticipated

- Technological innovations driving market expansion

- Comprehensive analysis covering 2024-2032 period

- Potential for enhanced aerospace component manufacturing

As aerospace companies increasingly adopt additive manufacturing technologies, the market is projected to experience a remarkable transformation, promising efficiency, cost-effectiveness, and unprecedented design flexibility.

Revolutionizing Aerospace: The Transformative Power of Additive Manufacturing in 2024 and Beyond

In the rapidly evolving landscape of aerospace technology, a groundbreaking transformation is taking place that promises to reshape the entire industry. Additive manufacturing, once a niche technology, has emerged as a critical driver of innovation, efficiency, and technological advancement in aerospace engineering, offering unprecedented opportunities for design flexibility, cost reduction, and performance optimization.Unleashing the Future: Where Innovation Meets Precision Manufacturing

The Technological Renaissance in Aerospace Engineering

The aerospace industry stands on the cusp of a remarkable technological revolution, with additive manufacturing emerging as a game-changing methodology. Traditional manufacturing approaches are being systematically dismantled and reconstructed through advanced 3D printing technologies that enable unprecedented levels of precision and complexity. Engineers and designers now possess the capability to create intricate components with geometries that were previously impossible to manufacture, pushing the boundaries of what's achievable in aerospace design. Sophisticated metal printing techniques have dramatically transformed component production, allowing for lighter, stronger, and more aerodynamic structures. Aerospace manufacturers are leveraging these advanced technologies to develop components that reduce overall aircraft weight, enhance fuel efficiency, and improve structural integrity. The ability to produce complex, integrated parts in a single manufacturing process represents a paradigm shift in how aerospace components are conceptualized and created.Economic and Strategic Implications of Additive Manufacturing

The economic landscape of aerospace manufacturing is undergoing a profound metamorphosis driven by additive manufacturing technologies. Companies are discovering substantial cost savings through reduced material waste, simplified supply chains, and accelerated prototyping processes. By eliminating traditional manufacturing constraints, organizations can now develop and test innovative designs with remarkable speed and precision. Strategic investments in additive manufacturing are creating competitive advantages for forward-thinking aerospace companies. The technology enables rapid customization, reduced time-to-market, and enhanced product performance. Moreover, the ability to produce complex parts on-demand reduces inventory costs and provides unprecedented flexibility in manufacturing strategies.Sustainability and Environmental Considerations

Additive manufacturing is not just a technological marvel but also a critical tool in addressing environmental challenges within the aerospace industry. By enabling more efficient material usage and reducing overall manufacturing waste, 3D printing technologies contribute significantly to sustainable manufacturing practices. The ability to create lighter components directly translates to reduced fuel consumption and lower carbon emissions. Advanced computational modeling and simulation techniques are being integrated with additive manufacturing processes, allowing engineers to optimize designs for maximum performance and minimal environmental impact. This holistic approach represents a significant step towards creating more sustainable and environmentally responsible aerospace technologies.Global Market Dynamics and Future Projections

Market analysts project exponential growth in the aerospace additive manufacturing sector, with expectations of substantial expansion between 2024 and 2032. The convergence of technological innovation, strategic investments, and increasing industry adoption suggests a robust and dynamic market landscape. Emerging economies are increasingly investing in advanced manufacturing technologies, further accelerating global market development. Key technological advancements, including improved material sciences, more sophisticated printing techniques, and enhanced computational capabilities, are expected to drive continuous innovation. The integration of artificial intelligence and machine learning with additive manufacturing processes will likely unlock even more sophisticated manufacturing capabilities in the coming years.Challenges and Opportunities on the Horizon

Despite the tremendous potential, the aerospace additive manufacturing sector faces significant challenges. Regulatory compliance, material certification, and consistent quality control remain critical areas requiring continuous improvement. Industry stakeholders must collaborate to develop standardized processes and comprehensive quality assurance frameworks. However, these challenges also present extraordinary opportunities for innovation. Companies that can successfully navigate these complexities and develop robust, reliable additive manufacturing solutions will position themselves at the forefront of aerospace technological advancement.RELATED NEWS

Breaking Barriers: How Next-Gen Tech is Revolutionizing Metal Manufacturing

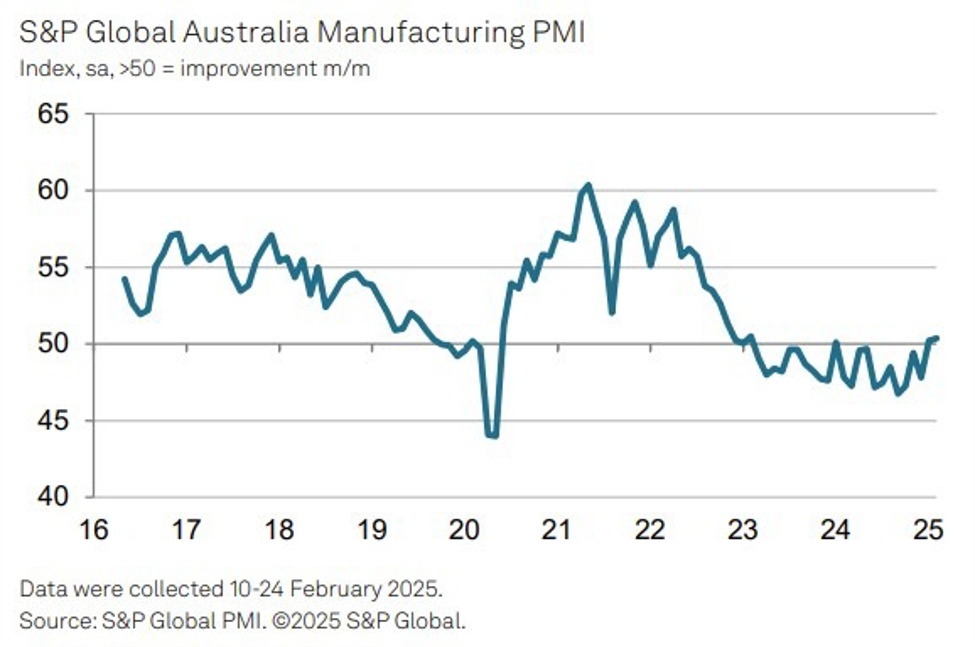

Manufacturing Momentum: Australia's Industrial Pulse Ticks Upward in February

:quality(70):focal(2538x1153:2548x1163)/cloudfront-us-east-1.images.arcpublishing.com/shawmedia/RBK6A3NJPJCNTKWV4K7BAXHTVU.jpg)