Rocket Boost: US Defense Firms Accelerate Solid Motor Production in Strategic New Partnership

Manufacturing

2025-03-15 15:37:00Content

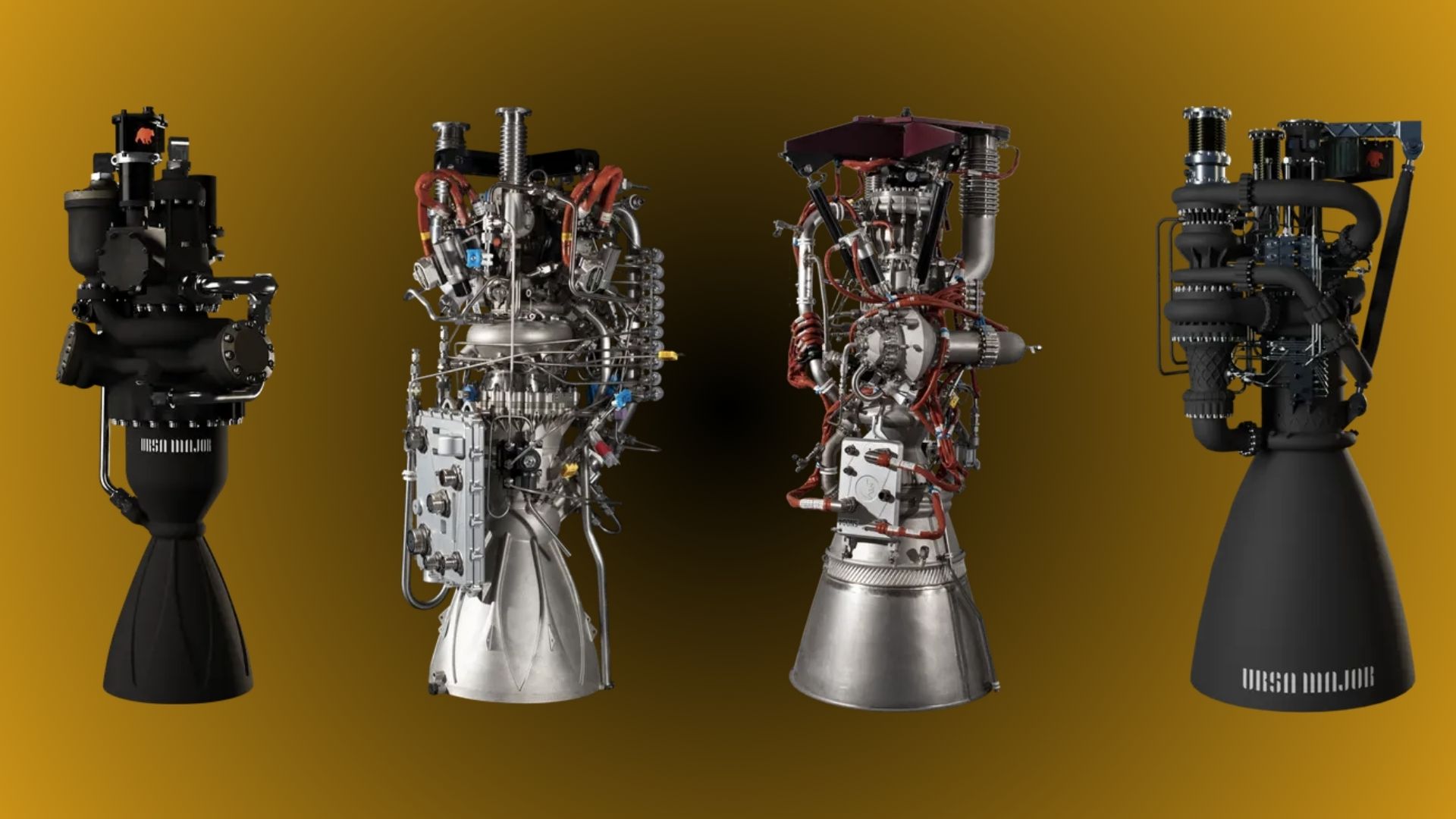

In a strategic collaboration that promises to revolutionize rocket propulsion manufacturing, Colorado-based aerospace company Ursa Major has joined forces with Palantir Technologies. The partnership leverages Palantir's cutting-edge Warp Speed manufacturing operating system to dramatically enhance the efficiency and precision of rocket engine production.

By integrating Palantir's advanced technological platform, Ursa Major aims to streamline its manufacturing processes, potentially reducing production time and improving overall operational performance. The Warp Speed technology is expected to provide unprecedented insights and optimization capabilities, enabling the company to accelerate its rocket propulsion development and manufacturing workflows.

This collaboration represents a significant milestone in the aerospace industry, highlighting the growing importance of sophisticated software solutions in advanced manufacturing. As space exploration and commercial spaceflight continue to evolve, partnerships like this underscore the critical role of innovative technologies in pushing the boundaries of rocket engineering.

Rocket Manufacturing Revolution: How Ursa Major and Palantir Are Transforming Aerospace Production

In the rapidly evolving landscape of aerospace technology, groundbreaking collaborations are reshaping how advanced propulsion systems are designed, manufactured, and deployed. The intersection of cutting-edge software solutions and innovative rocket engineering represents a pivotal moment in industrial transformation, promising to accelerate space exploration and manufacturing efficiency.Pioneering the Future of Rocket Manufacturing with Unprecedented Technological Synergy

The Strategic Partnership Redefining Aerospace Manufacturing

The collaboration between Ursa Major, a prominent Colorado-based rocket propulsion innovator, and Palantir Technologies marks a significant milestone in aerospace manufacturing. By integrating Palantir's sophisticated Warp Speed manufacturing operating system, the partnership aims to revolutionize the complex and precision-driven process of rocket engine production. This strategic alliance represents more than a mere technological integration; it symbolizes a fundamental reimagining of how advanced aerospace components are conceptualized, engineered, and brought to life. The Warp Speed platform introduces unprecedented levels of operational intelligence, enabling real-time data analysis, predictive maintenance, and streamlined production workflows. By leveraging advanced algorithmic capabilities, the system can identify potential manufacturing bottlenecks, optimize resource allocation, and dramatically reduce the time-to-market for critical rocket propulsion systems.Technological Innovation at the Intersection of Software and Aerospace Engineering

Palantir's technological prowess brings a transformative approach to rocket manufacturing, introducing machine learning algorithms and sophisticated data analytics that can predict and mitigate potential manufacturing challenges. The Warp Speed platform goes beyond traditional manufacturing management systems by providing granular insights into every stage of the production process. For Ursa Major, this partnership represents an opportunity to leverage cutting-edge software solutions to enhance their already impressive rocket engine manufacturing capabilities. By integrating advanced data analytics and predictive modeling, the company can potentially reduce production costs, minimize errors, and accelerate innovation cycles.Implications for Global Space Exploration and Industrial Manufacturing

The collaboration between Ursa Major and Palantir extends far beyond their immediate operational objectives. It signals a broader trend of technological convergence, where software intelligence and advanced engineering intersect to create unprecedented manufacturing capabilities. This approach could potentially reshape not just aerospace production, but serve as a blueprint for advanced manufacturing across multiple high-tech industries. The implementation of such sophisticated manufacturing technologies suggests a future where production processes are increasingly intelligent, adaptive, and responsive. Machine learning algorithms can continuously optimize manufacturing workflows, predict maintenance requirements, and ensure consistently high-quality output with minimal human intervention.Economic and Technological Ripple Effects

By demonstrating the potential of integrated software solutions in specialized manufacturing environments, Ursa Major and Palantir are setting new industry standards. Their collaborative approach suggests that the future of advanced manufacturing lies in the seamless integration of data intelligence, predictive analytics, and domain-specific engineering expertise. The economic implications are profound. More efficient manufacturing processes translate directly into reduced production costs, faster innovation cycles, and potentially more accessible space exploration technologies. As private and public entities continue to invest in space exploration, such technological innovations become increasingly critical to maintaining competitive advantages.Looking Toward a More Intelligent Manufacturing Ecosystem

The partnership between Ursa Major and Palantir represents more than a technological collaboration; it embodies a vision of how intelligent systems can transform complex industrial processes. By reimagining manufacturing through the lens of data intelligence and adaptive technologies, they are not just improving current production methods but laying the groundwork for future technological breakthroughs.RELATED NEWS

Manufacturing

Manufacturing Innovation Spotlight: Textron Aviation Clinches SME's Prestigious 2025 Excellence Award

2025-05-06 09:21:00

Manufacturing

Biotech Giant Amgen Supercharges Ohio Expansion with Massive Manufacturing Upgrade

2025-04-25 17:12:25

Manufacturing

Trade War Tug-of-War: Can Tariffs Resurrect America's Industrial Heartland?

2025-03-09 14:56:00