Safety Alert: Boeing 787 Dreamliners Grounded for Critical Structural Checks

Manufacturing

2025-03-14 20:49:27Content

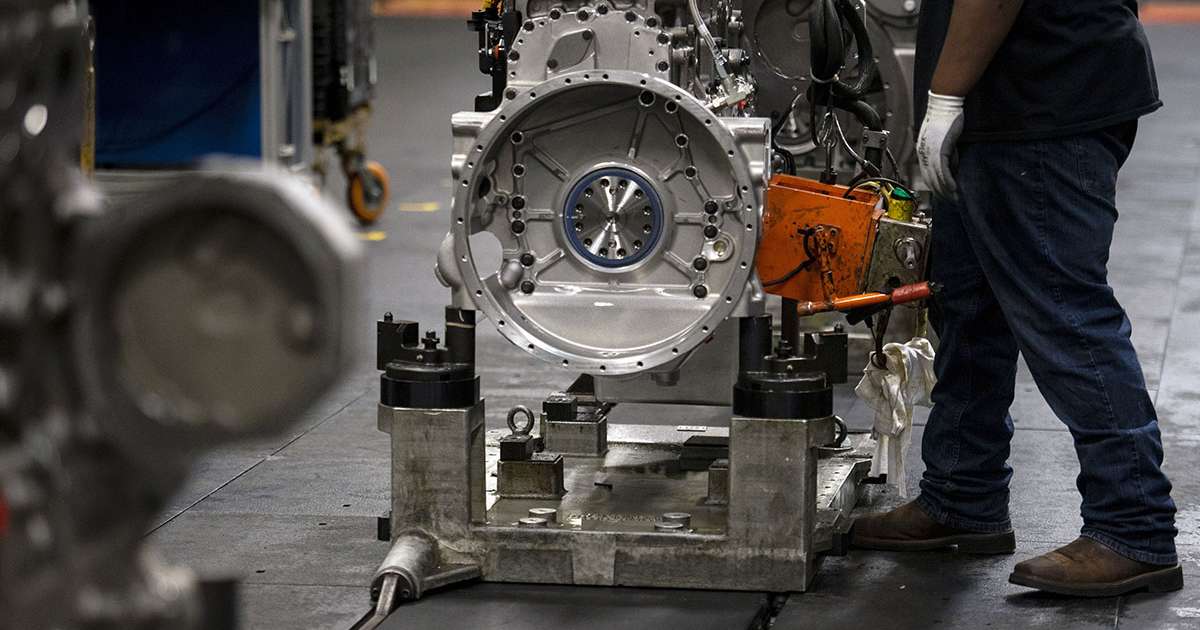

In a proactive move to ensure passenger safety, the Federal Aviation Administration (FAA) has mandated comprehensive inspections of Boeing 787 Dreamliner aircraft, focusing specifically on potential manufacturing defects in the forward-pressure bulkheads. These critical structural components have raised concerns due to potential gaps that could compromise the aircraft's integrity.

The directive targets the precise area where the forward-pressure bulkhead—a crucial element that helps maintain cabin pressurization and structural stability—may have been imperfectly manufactured. Airlines operating 787 Dreamliners are now required to conduct thorough examinations to identify and address any potential structural inconsistencies.

By implementing these mandatory inspections, the FAA aims to preemptively detect and rectify any manufacturing anomalies before they can pose a risk to flight safety. This proactive approach underscores the agency's commitment to maintaining the highest standards of aviation safety and ensuring passenger confidence in commercial air travel.

Affected airlines must meticulously follow the FAA's guidelines, carefully examining each aircraft's forward-pressure bulkhead to verify its structural soundness and eliminate any potential manufacturing defects.

Aviation Safety Alert: Boeing 787 Dreamliner Structural Integrity Under Microscope

In the high-stakes world of aviation safety, the Federal Aviation Administration (FAA) has once again demonstrated its unwavering commitment to passenger protection by launching a critical investigation into potential manufacturing vulnerabilities affecting the Boeing 787 Dreamliner's structural components.Precision Engineering Meets Rigorous Safety Protocols

The Critical Pressure Bulkhead Examination

The Boeing 787 Dreamliner, a marvel of modern aerospace engineering, has found itself at the center of an intense safety scrutiny. Aviation regulators have identified potential manufacturing anomalies in the aircraft's forward-pressure bulkhead that could compromise structural integrity. These microscopic gaps, though seemingly insignificant, represent a potential risk that demands immediate and comprehensive investigation. Aerospace engineers and technical experts are meticulously analyzing the manufacturing processes, employing advanced non-destructive testing techniques to identify and assess potential structural weaknesses. The precision required in such examinations is comparable to performing microsurgery on a complex mechanical organism, where even the most minute imperfection could have cascading implications for aircraft safety.Manufacturing Precision in Modern Aviation

The complexity of modern aircraft manufacturing involves an intricate dance of technological innovation and human expertise. Boeing's 787 Dreamliner represents a pinnacle of aerospace design, incorporating advanced composite materials and cutting-edge engineering principles. However, the current FAA directive underscores the perpetual challenge of maintaining absolute manufacturing perfection. Each pressure bulkhead serves as a critical structural element, essentially acting as a protective barrier that maintains the aircraft's internal pressure during flight. Any deviation from precise manufacturing specifications could potentially compromise the aircraft's ability to withstand extreme atmospheric conditions and maintain passenger safety.Regulatory Oversight and Industry Response

The FAA's proactive approach demonstrates a robust safety culture within the aviation industry. By mandating comprehensive inspections, regulators are not merely identifying potential risks but actively preventing potential catastrophic scenarios. Airlines operating the Boeing 787 fleet are now required to conduct thorough examinations, ensuring that each aircraft meets the most stringent safety standards. This directive reflects a broader commitment to continuous improvement and risk mitigation in aerospace engineering. It represents a collaborative effort between manufacturers, airlines, and regulatory bodies to maintain the highest possible safety standards in commercial aviation.Technological Implications and Future Developments

The current investigation serves as a catalyst for potential technological advancements in aircraft manufacturing. By identifying and addressing these microscopic structural challenges, the aviation industry can develop more sophisticated quality control mechanisms and advanced manufacturing techniques. Emerging technologies such as artificial intelligence, machine learning, and advanced computational modeling are increasingly being integrated into quality assurance processes. These innovations promise to revolutionize how manufacturers detect and prevent potential structural anomalies, potentially transforming the landscape of aerospace engineering.Global Aviation Safety Ecosystem

This incident highlights the interconnected nature of global aviation safety. A directive from the FAA can have immediate and far-reaching consequences, potentially influencing regulatory approaches in other countries and setting new benchmarks for aircraft maintenance and inspection protocols. The Boeing 787 Dreamliner, despite this current scrutiny, remains a testament to human engineering capabilities. The ongoing investigation represents not a failure but a continuous commitment to pushing the boundaries of safety and technological excellence in commercial aviation.RELATED NEWS

Manufacturing

Robotic Revolution: Inside Apple's Bold Plan to Transform iPhone Production in the US

2025-04-30 01:25:16

Manufacturing

Arsenal Evolution: How America's Defense Industry Is Reshaping Modern Warfare

2025-03-26 08:00:00

Manufacturing

Trade War Tremors: Manufacturing Sector Hits Lowest Point in Three Years

2025-04-28 22:02:17