Inside GM's Tech Revolution: AI Transforms Factory Floors with Smarter, Safer Production

Manufacturing

2025-03-11 18:23:59Content

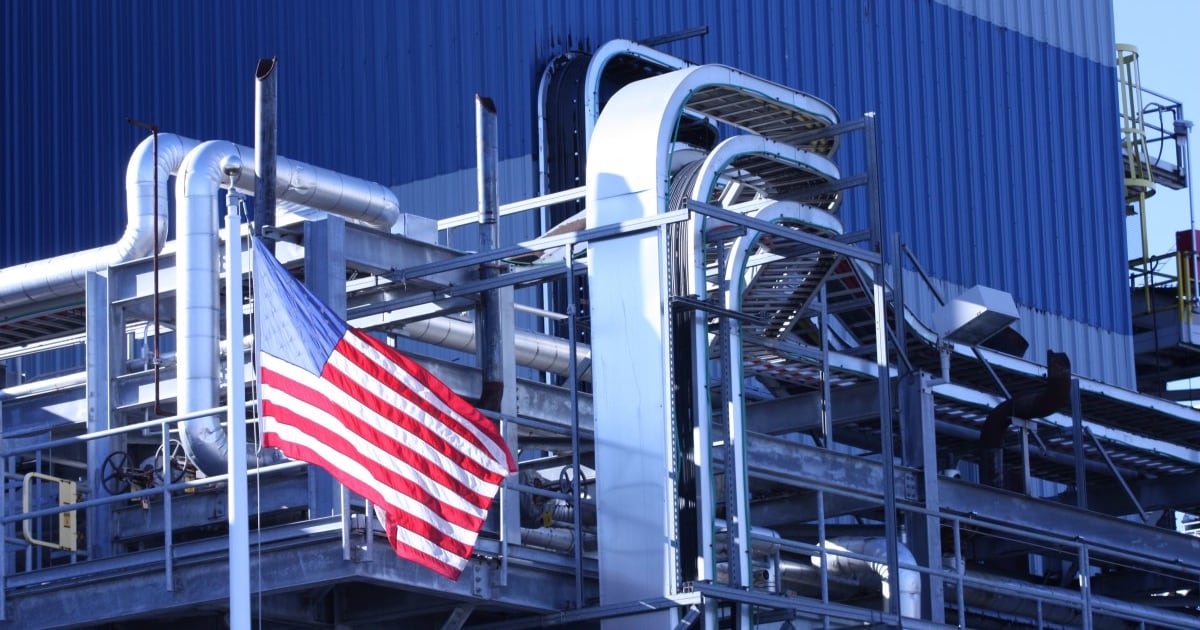

General Motors is revolutionizing its manufacturing approach by strategically integrating artificial intelligence across its production ecosystem. The automotive giant is leveraging cutting-edge AI technologies to transform multiple aspects of its manufacturing operations, focusing on three critical areas: operational efficiency, vehicle quality, and workplace safety.

By implementing advanced machine learning algorithms and intelligent systems, GM is creating smarter, more responsive manufacturing processes. These AI-driven innovations enable the company to optimize production workflows, detect potential quality issues before they escalate, and create a more proactive safety environment for its workforce.

The AI integration goes beyond traditional automation, providing real-time insights and predictive capabilities that help GM streamline its manufacturing strategies. From intelligent quality control systems that can identify microscopic defects to sophisticated safety monitoring tools that anticipate potential workplace risks, the company is demonstrating how artificial intelligence can fundamentally reshape modern manufacturing.

As GM continues to invest in these transformative technologies, it is positioning itself at the forefront of the automotive industry's technological evolution, showcasing how AI can drive innovation, enhance productivity, and create safer, more efficient manufacturing environments.

Revolutionizing Manufacturing: General Motors' AI-Powered Transformation Reshapes Industrial Innovation

In the rapidly evolving landscape of automotive manufacturing, General Motors stands at the forefront of a technological revolution, leveraging artificial intelligence to fundamentally reimagine production processes, worker safety, and operational efficiency. The automotive giant is pioneering a bold new approach that promises to redefine the intersection of human expertise and cutting-edge technological innovation.Unleashing the Power of AI: A Game-Changing Manufacturing Strategy

Intelligent Manufacturing Ecosystem

General Motors is implementing a comprehensive AI-driven transformation that goes far beyond traditional manufacturing methodologies. By integrating advanced machine learning algorithms and sophisticated neural networks, the company is creating an intelligent manufacturing ecosystem that continuously adapts and optimizes production processes in real-time. These sophisticated systems analyze vast streams of data from production lines, equipment sensors, and worker interactions, identifying potential inefficiencies and predictive maintenance opportunities with unprecedented precision. The AI-powered infrastructure enables unprecedented levels of quality control, detecting microscopic variations and potential defects that might escape human observation. Machine vision systems equipped with deep learning capabilities can instantaneously scan automotive components, ensuring each part meets exacting standards with a level of accuracy that surpasses traditional quality assurance methods.Worker Safety and Augmented Intelligence

Beyond production optimization, General Motors is revolutionizing workplace safety through intelligent technological interventions. Advanced AI systems monitor worker environments, identifying potential hazards and ergonomic risks in milliseconds. Wearable technologies integrated with machine learning algorithms provide real-time feedback, helping employees maintain optimal working conditions and reducing the likelihood of workplace accidents. Collaborative robots, or cobots, represent another frontier of AI implementation. These intelligent machines work alongside human workers, handling repetitive or physically demanding tasks while maintaining a symbiotic relationship that enhances overall productivity and worker well-being. The AI systems continuously learn from human interactions, creating a dynamic and adaptive workplace environment.Predictive Maintenance and Resource Optimization

General Motors' AI strategy extends deep into equipment management and resource allocation. Sophisticated predictive maintenance algorithms analyze complex machinery performance data, anticipating potential failures before they occur. This proactive approach minimizes unexpected downtime, reduces maintenance costs, and extends the operational lifespan of critical manufacturing equipment. The AI-driven resource optimization models dynamically adjust production schedules, material allocation, and workforce deployment based on real-time demand forecasts. By processing multiple variables simultaneously, these intelligent systems can make split-second decisions that maximize efficiency and minimize waste, representing a quantum leap in manufacturing management.Sustainable Innovation and Environmental Impact

The integration of artificial intelligence into manufacturing processes also yields significant environmental benefits. By optimizing energy consumption, reducing material waste, and creating more efficient production cycles, General Motors is demonstrating how technological innovation can drive sustainability. The AI systems continuously analyze and suggest improvements in energy utilization, carbon footprint reduction, and resource conservation. These intelligent technologies enable more precise material usage, recycling strategies, and energy management, positioning General Motors as a leader in environmentally responsible manufacturing. The company's commitment to AI-driven sustainability represents a holistic approach to industrial innovation that balances technological advancement with ecological consciousness.RELATED NEWS

Manufacturing

Forging the Future: Siemens and Michigan Unite to Revolutionize Metal 3D Printing Education

2025-02-24 16:23:46

Manufacturing

Trade War Fallout: Massachusetts Manufacturers Caught in China's Economic Crosshairs

2025-05-04 10:00:01

Manufacturing

Pharma Pivot: Speranza Launches Bold Generics Venture Amid US Manufacturing Renaissance

2025-04-30 10:43:56