Manufacturing Comeback: Biden's Tariff Strategy Faces Uphill Battle in Industrial Revival

Manufacturing

2025-03-11 12:34:20Content

The American industrial landscape has undergone a dramatic transformation since the 1970s, with manufacturing jobs and critical infrastructure experiencing a significant decline. What was once the backbone of the nation's economic strength has gradually eroded, leaving behind a complex challenge of economic revitalization.

Decades of outsourcing, technological shifts, and global economic changes have systematically dismantled the robust manufacturing sector that once defined American economic prowess. The once-thriving industrial heartlands have been hollowed out, with factories closing and communities struggling to adapt to a rapidly changing economic environment.

Rebuilding this lost industrial capacity is not a quick fix. Experts estimate that restoring manufacturing jobs and modernizing infrastructure will require years of strategic investment, workforce retraining, and comprehensive economic policies. The path to recovery demands a multifaceted approach that addresses technological innovation, education, and sustainable economic development.

As the United States seeks to reclaim its industrial might, policymakers and business leaders face the critical task of reimagining manufacturing for the 21st century. The challenge lies not just in creating jobs, but in developing a resilient, adaptive industrial ecosystem that can compete in a global, technology-driven marketplace.

The Vanishing Heartland: America's Manufacturing Landscape in Transformation

In the intricate tapestry of American economic history, few narratives are as poignant and transformative as the decline of manufacturing and infrastructure. What was once the backbone of industrial prowess has gradually eroded, leaving behind a complex landscape of economic challenges and potential reinvention.Rebuilding America's Industrial Backbone: A Journey of Resilience and Reinvention

The Historical Trajectory of Industrial Decline

The post-1970s era marked a pivotal turning point for American manufacturing, characterized by a profound structural transformation that would reshape the nation's economic ecosystem. Globalization, technological disruption, and shifting economic paradigms converged to create an unprecedented challenge for traditional manufacturing centers. Cities once bustling with factory activity found themselves grappling with massive job losses and economic uncertainty. Technological advancements and international competition fundamentally altered the manufacturing landscape. Automation, artificial intelligence, and global supply chains systematically replaced traditional manufacturing models, creating a seismic shift in employment patterns and industrial capabilities.Economic Implications of Manufacturing Transformation

The erosion of manufacturing jobs represents more than a statistical decline; it symbolizes a profound socioeconomic restructuring. Communities that had historically depended on industrial employment found themselves navigating unprecedented economic transitions. The ripple effects extended beyond immediate job losses, impacting local economies, educational systems, and social infrastructures. Economists and policy experts have long debated the strategies for revitalizing these sectors. The challenge lies not merely in recreating past industrial models but in developing innovative approaches that align with contemporary technological and economic realities.Infrastructure Challenges and Potential Regeneration

Infrastructure development emerges as a critical component in addressing manufacturing's systemic challenges. The United States faces significant investment requirements to modernize transportation networks, digital infrastructure, and industrial facilities. These investments represent more than economic expenditures; they are strategic interventions designed to reposition the nation's competitive capabilities. Emerging technologies like advanced manufacturing, robotics, and sustainable production methods offer promising pathways for regeneration. Public-private partnerships, targeted federal investments, and strategic workforce retraining programs could potentially catalyze a renaissance in American industrial capabilities.Workforce Adaptation and Skills Transformation

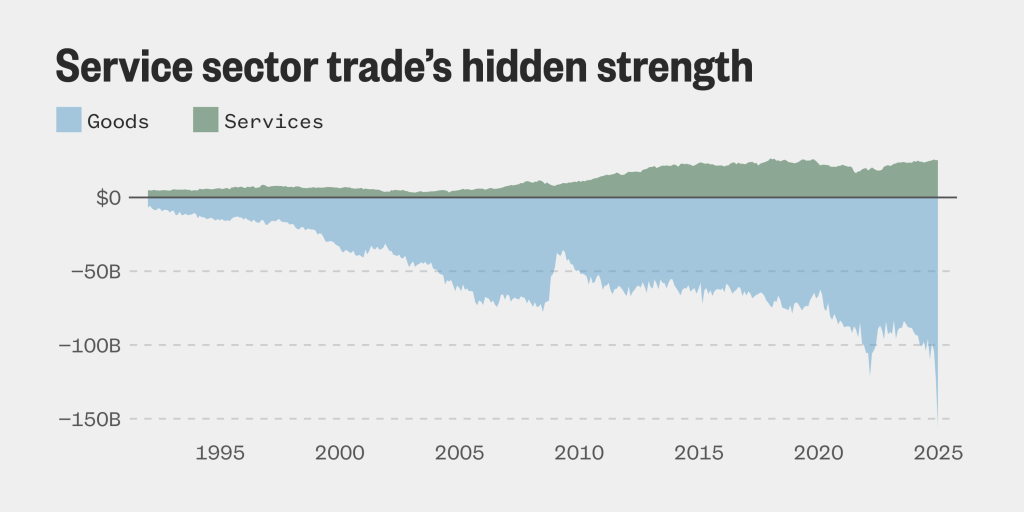

The contemporary manufacturing landscape demands a radical reimagining of workforce skills. Traditional manufacturing roles are increasingly being replaced by technologically sophisticated positions requiring advanced digital literacy, programming skills, and complex problem-solving capabilities. Educational institutions and vocational training programs must evolve to bridge the skills gap, creating adaptive learning environments that prepare workers for the technological demands of modern manufacturing ecosystems. This transformation represents a critical investment in human capital and national economic resilience.Global Competitive Dynamics

In an increasingly interconnected global economy, the United States must strategically position itself to compete with emerging industrial powerhouses. This requires a multifaceted approach encompassing technological innovation, strategic policy interventions, and a commitment to developing cutting-edge manufacturing capabilities. The future of American manufacturing lies not in nostalgic recreations of past industrial models but in bold, forward-looking strategies that leverage technological innovation, human creativity, and adaptive economic frameworks.RELATED NEWS

Manufacturing

Manufacturing's New Crusade: Lobbying Group Aims to Revive Trump's Industrial Vision

2025-03-21 12:48:29

Manufacturing

Storage Giant Vetter Unleashes Massive Warehouse Expansion, Signals Major Logistics Breakthrough

2025-03-17 14:30:00

Manufacturing

Reviving American Manufacturing: The Key to National Resilience and Strength

2025-04-08 19:57:22