Breaking: AI and 5G Revolution Transforms Factory Floors Overnight

Manufacturing

2025-03-10 03:13:49Content

Smart Manufacturing Transformed: The AI and 5G Revolution

In the rapidly evolving landscape of industrial innovation, artificial intelligence (AI) and private 5G networks are revolutionizing manufacturing, creating unprecedented opportunities for efficiency, connectivity, and intelligent decision-making.

The Convergence of Cutting-Edge Technologies

Modern manufacturers are experiencing a paradigm shift as AI and private 5G networks converge to create smarter, more responsive production environments. This technological synergy is not just an incremental improvement, but a fundamental transformation of industrial operations.

Key Advantages of AI-Powered Smart Manufacturing

- Real-time data processing and analysis

- Enhanced predictive maintenance capabilities

- Dramatically improved operational efficiency

- Reduced downtime and maintenance costs

Private 5G: The Connectivity Backbone

Private 5G networks provide the critical infrastructure that enables seamless communication between advanced AI systems, IoT devices, and manufacturing equipment. With ultra-low latency and high-bandwidth capabilities, these networks support complex, data-intensive industrial processes like never before.

Transformative Impact Across Industries

From automotive manufacturing to pharmaceutical production, AI and private 5G are breaking down traditional barriers, enabling more agile, intelligent, and responsive production systems. Companies embracing these technologies are gaining significant competitive advantages in an increasingly digital global marketplace.

Looking Ahead: The Future of Smart Manufacturing

As AI algorithms become more sophisticated and 5G networks continue to expand, we can expect even more remarkable innovations in manufacturing. The future promises fully autonomous production lines, predictive supply chain management, and unprecedented levels of operational intelligence.

The manufacturing revolution is here, powered by the remarkable potential of AI and private 5G networks.

Revolutionary Convergence: How AI and Private 5G Are Transforming Smart Manufacturing Landscapes

In an era of unprecedented technological acceleration, manufacturing industries are experiencing a profound metamorphosis driven by cutting-edge digital innovations. The intersection of artificial intelligence and private 5G networks is creating unprecedented opportunities for industrial transformation, redefining operational efficiency, and unlocking potential that was previously unimaginable.Unleashing Industrial Potential Through Technological Synergy

The Paradigm Shift in Manufacturing Intelligence

Modern manufacturing is no longer just about production; it's about intelligent, adaptive ecosystems that can predict, respond, and optimize in real-time. Artificial intelligence has emerged as a transformative force, enabling manufacturers to transcend traditional operational boundaries. By integrating advanced machine learning algorithms with robust private 5G infrastructure, companies can create hyper-connected environments that dramatically enhance decision-making capabilities. The convergence of AI and private 5G networks represents more than technological integration—it's a fundamental reimagining of industrial processes. These technologies enable unprecedented levels of data transmission, processing, and analysis, allowing manufacturers to develop predictive maintenance strategies, optimize supply chain dynamics, and create more responsive production systems.Private 5G: The Connectivity Backbone of Smart Manufacturing

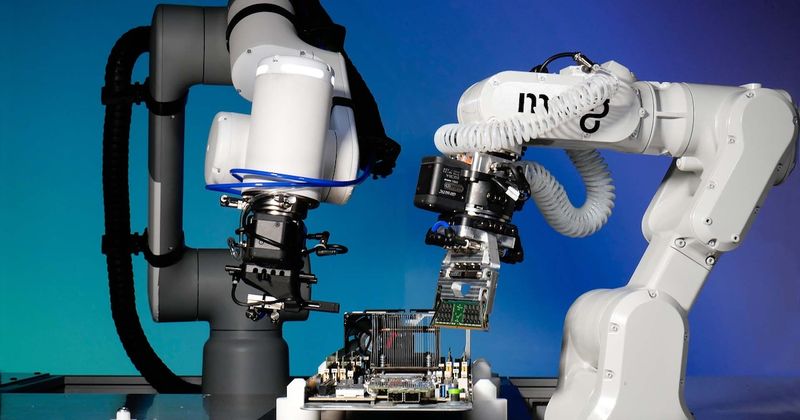

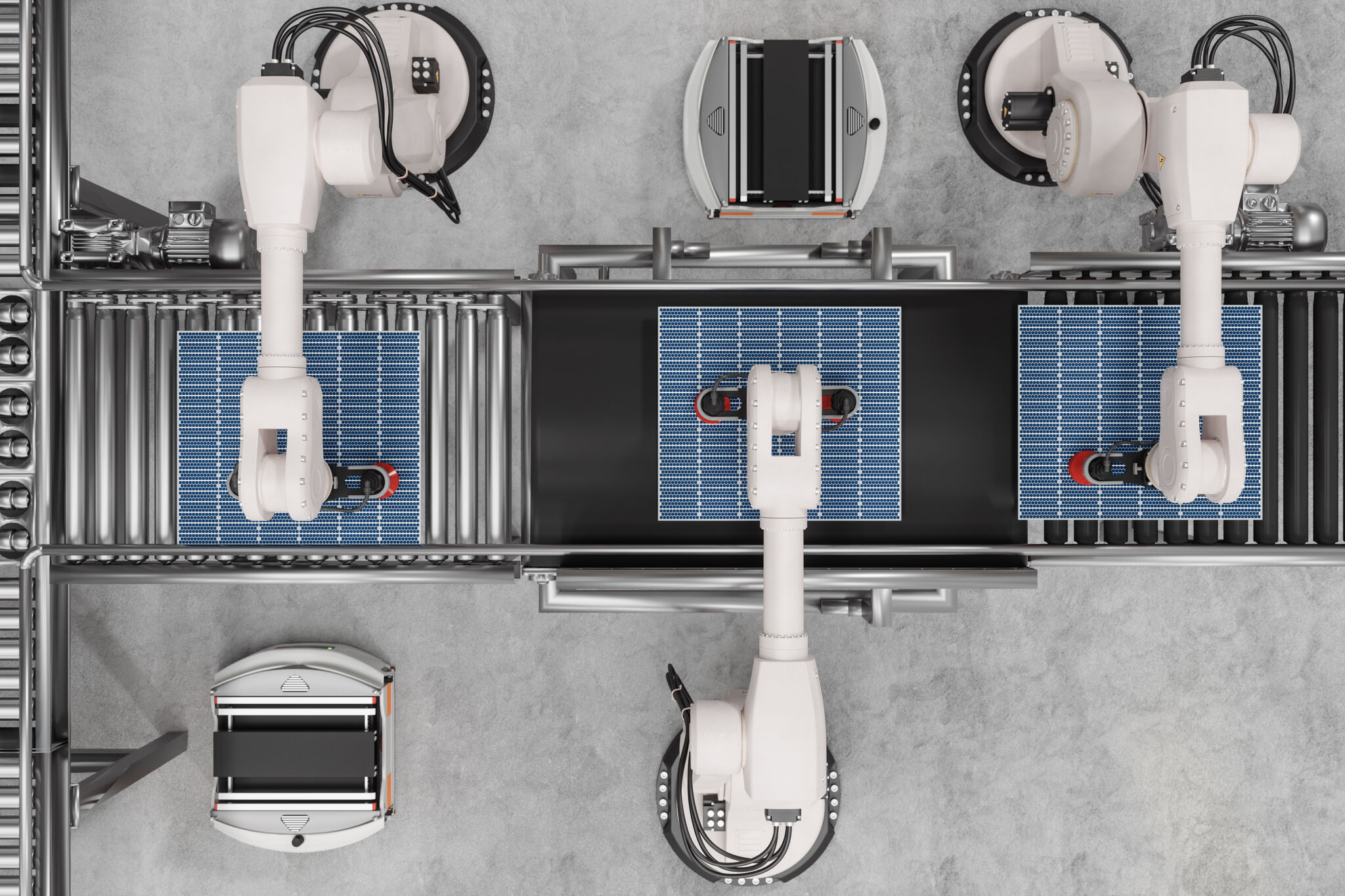

Private 5G networks are revolutionizing industrial connectivity by providing ultra-low latency, high-bandwidth communication channels that traditional networks cannot match. Unlike public networks, these dedicated infrastructures offer manufacturers unparalleled control, security, and performance. They create robust, reliable communication frameworks that can support complex industrial Internet of Things (IoT) ecosystems. By implementing private 5G, manufacturers gain the ability to deploy sophisticated sensor networks, autonomous robotics, and real-time monitoring systems with unprecedented precision. These networks support mission-critical applications that require instantaneous data transmission and minimal interference, transforming factory floors into intelligent, responsive environments.Artificial Intelligence: The Cognitive Layer of Smart Manufacturing

Artificial intelligence serves as the cognitive engine driving smart manufacturing's evolution. Machine learning algorithms can analyze vast datasets generated by industrial systems, extracting insights that human analysts might overlook. These AI-driven insights enable predictive maintenance, quality control optimization, and dynamic resource allocation. Advanced neural networks can now simulate complex manufacturing scenarios, predict potential equipment failures, and recommend preemptive interventions. This predictive capability represents a quantum leap in industrial management, shifting paradigms from reactive maintenance to proactive, intelligence-driven strategies.Cybersecurity and Technological Resilience

As manufacturing becomes increasingly digitized, robust cybersecurity measures become paramount. Private 5G networks, combined with AI-powered security protocols, create multi-layered defense mechanisms that protect critical industrial infrastructure from potential cyber threats. These advanced systems can detect, analyze, and neutralize potential security breaches in milliseconds. Intelligent threat detection algorithms continuously monitor network traffic, identifying anomalous patterns and potential vulnerabilities. By integrating machine learning with network security, manufacturers can develop adaptive, self-healing technological ecosystems that maintain operational integrity.Economic and Competitive Implications

The strategic implementation of AI and private 5G technologies offers significant competitive advantages. Manufacturers who successfully integrate these technologies can achieve substantial cost reductions, improved product quality, and accelerated innovation cycles. The ability to rapidly adapt to changing market conditions becomes a core competitive differentiator. Early adopters of these technologies are positioning themselves at the forefront of the fourth industrial revolution, creating more agile, efficient, and responsive manufacturing environments that can quickly scale and adapt to global market dynamics.RELATED NEWS

Chip Investment Alert: SLT Holdings Doubles Down on Taiwan Semiconductor's Market Dominance

Reviving American Industry: Senators Loeffler and Ernst Unveil Bold Manufacturing Boost Act