Manufacturing Mirage: The Hidden Costs of Trump's American Job Revival Plan

Manufacturing

2025-04-29 18:08:05Content

The Transformation of American Manufacturing: A Story of Resilience and Reinvention

The landscape of American manufacturing has undergone a dramatic metamorphosis over the past few decades. What was once a thriving sector dominated by traditional factory jobs has been reshaped by globalization, technological innovation, and economic shifts.

When countless manufacturing jobs were shipped overseas in search of lower labor costs, many communities were left reeling. Factories that had been the economic backbone of towns and cities suddenly stood empty, their machinery silent. Workers who had built careers in manufacturing found themselves facing uncertain futures.

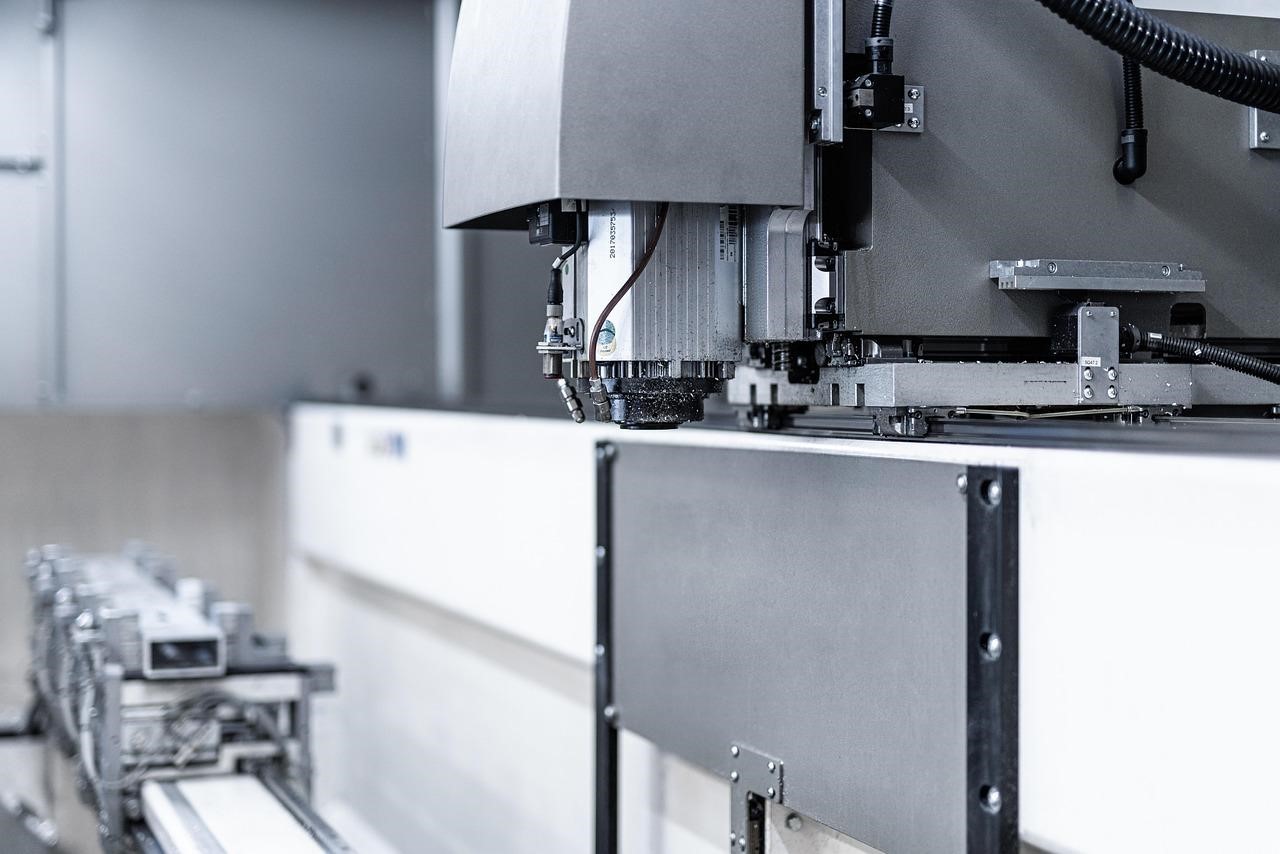

But the story doesn't end there. American manufacturing has proven remarkably adaptable. Advanced technologies like robotics, artificial intelligence, and precision manufacturing have breathed new life into the industry. Today's factories are high-tech environments where skilled workers operate sophisticated equipment and drive innovation.

Moreover, there's a growing trend of reshoring, with companies recognizing the strategic value of producing goods domestically. Quality control, shorter supply chains, and the ability to quickly respond to market changes are making local manufacturing increasingly attractive.

The workforce has also transformed. Modern manufacturing jobs require higher-level skills, offering competitive wages and opportunities for professional growth. Technical training programs and community colleges are now preparing a new generation of workers for these sophisticated roles.

While challenges remain, the resilience of American manufacturing tells a powerful story of adaptation, innovation, and hope. It's a testament to the creativity and determination that have always defined the American industrial spirit.

The Industrial Renaissance: Reshaping America's Manufacturing Landscape in the Global Economy

In the complex tapestry of global economic transformation, the United States stands at a critical crossroads, where manufacturing strategies are being radically reimagined and reconstructed. The traditional narrative of offshore production is rapidly evolving, challenging long-held assumptions about industrial competitiveness and economic sustainability.Navigating the Future: Bold Strategies for American Industrial Resurgence

The Shifting Paradigm of Global Manufacturing

The contemporary manufacturing ecosystem represents a dynamic and intricate landscape far removed from traditional models. Technological advancements, geopolitical tensions, and economic recalibrations have fundamentally transformed how nations approach industrial production. Emerging technologies like artificial intelligence, advanced robotics, and precision manufacturing are redefining the parameters of industrial competitiveness. Sophisticated manufacturing strategies now demand unprecedented levels of technological integration and strategic foresight. Companies are increasingly recognizing that competitive advantage stems not just from cost reduction, but from innovation, adaptability, and strategic positioning within complex global supply chains.Economic Implications of Domestic Production Revival

Reimagining domestic manufacturing requires a multifaceted approach that transcends simplistic economic calculations. The potential economic benefits extend far beyond immediate job creation, encompassing broader considerations of national economic resilience, technological innovation, and strategic independence. Economists and policy experts are increasingly advocating for a nuanced approach that balances global interconnectedness with strategic domestic capabilities. This involves creating robust ecosystems that support technological innovation, workforce development, and sustainable industrial practices.Technological Innovation and Industrial Transformation

The convergence of digital technologies and traditional manufacturing processes represents a revolutionary frontier in industrial development. Advanced manufacturing techniques like 3D printing, machine learning-driven quality control, and automated production systems are fundamentally restructuring how goods are conceived, designed, and produced. These technological innovations are not merely incremental improvements but represent fundamental reimaginings of industrial processes. They enable unprecedented levels of customization, efficiency, and precision, challenging traditional manufacturing paradigms and creating new competitive landscapes.Workforce Development and Skills Transformation

The renaissance of domestic manufacturing demands a corresponding revolution in workforce training and education. Traditional manufacturing skills are rapidly being supplanted by sophisticated technological competencies that require advanced technical knowledge and adaptive learning capabilities. Educational institutions, industry leaders, and government agencies must collaborate to develop comprehensive training programs that equip workers with the skills necessary to thrive in this new technological ecosystem. This involves creating flexible, technology-driven curricula that can rapidly adapt to emerging industrial trends.Geopolitical Dimensions of Manufacturing Strategy

Manufacturing strategies are increasingly intertwined with complex geopolitical considerations. National security, technological sovereignty, and economic resilience are becoming critical factors in industrial policy decisions. The ability to maintain robust domestic manufacturing capabilities is no longer just an economic imperative but a strategic national priority. Countries are recognizing that technological leadership and industrial self-sufficiency provide significant geopolitical advantages. This recognition is driving unprecedented levels of investment in domestic industrial infrastructure and technological innovation.Sustainable Manufacturing and Environmental Considerations

Modern manufacturing strategies must inherently incorporate sustainable practices and environmental consciousness. The integration of green technologies, circular economy principles, and carbon-neutral production methods are becoming essential components of competitive industrial strategies. Manufacturers are increasingly viewing sustainability not as a constraint but as an opportunity for innovation, cost reduction, and brand differentiation. This holistic approach represents a fundamental reimagining of industrial production's role in addressing global environmental challenges.RELATED NEWS

Manufacturing

Manufacturing Revolution: SKYX Joins Forces with Profab to Supercharge U.S. Industrial Growth

2025-04-03 14:02:00

Manufacturing

Pharma Giant LGM Breaks Ground: $6 Million Boost Transforms Texas Manufacturing Hub

2025-03-12 12:56:56

Manufacturing

From Precision to Prosperity: How Kimber Manufacturing Continues to Shape Troy's Industrial Landscape

2025-04-18 17:09:32