Slicing Budgets, Shrinking Shelves: FDA Cuts Threaten Food Industry's Future

Companies

2025-04-25 15:49:32Content

The food manufacturing landscape is poised for transformative regulatory shifts, according to David Lennarz, president of Registrar Corp. Industry leaders should prepare for a wave of comprehensive changes that will reshape operational protocols and compliance standards.

Manufacturers can expect a significant increase in plant inspection frequencies, signaling a more rigorous approach to food safety and quality control. The traditional inspection models are evolving, with regulators adopting more proactive and detailed examination strategies.

Self-affirmed Generally Recognized as Safe (GRAS) guidelines are also undergoing critical reevaluation. Food companies will need to be more transparent and thorough in documenting ingredient safety and providing comprehensive scientific evidence to support their claims.

Ingredient traceability is emerging as another key focus area. New regulations will likely demand more sophisticated tracking systems, enabling precise monitoring of food products from source to shelf. This enhanced traceability will not only improve food safety but also provide consumers with greater confidence in the products they purchase.

Lennarz emphasizes that these upcoming changes are not merely administrative adjustments, but fundamental shifts that will require strategic planning, technological investment, and a proactive compliance approach from food manufacturers across the industry.

Navigating the Future: Transformative Shifts in Food Manufacturing Regulations

The food manufacturing landscape is on the cusp of a dramatic transformation, with regulatory bodies poised to implement sweeping changes that will fundamentally reshape how food producers operate, ensure safety, and maintain transparency in their supply chains.Revolutionizing Food Safety: A Critical Turning Point for Manufacturers

Inspection Protocols: The New Frontier of Regulatory Oversight

Food manufacturers are facing an unprecedented era of heightened scrutiny and regulatory intervention. The traditional approaches to plant inspections are rapidly evolving, signaling a comprehensive overhaul of existing compliance mechanisms. Regulatory agencies are developing more sophisticated, data-driven methodologies that will dramatically increase the frequency and depth of facility assessments. The emerging inspection paradigm goes beyond surface-level evaluations, incorporating advanced technologies like artificial intelligence, real-time monitoring systems, and predictive analytics. These innovations will enable regulators to conduct more comprehensive and nuanced assessments of food production environments, identifying potential risks with unprecedented precision.Self-Affirmed GRAS Guidelines: Navigating Complex Regulatory Terrain

The landscape of Generally Recognized as Safe (GRAS) determinations is undergoing a radical transformation. Manufacturers will need to develop more rigorous, transparent processes for ingredient evaluation and self-affirmation. The new guidelines demand a more comprehensive approach to ingredient safety assessment, requiring extensive documentation, scientific validation, and proactive risk management strategies. Companies must invest in robust scientific research, interdisciplinary expertise, and sophisticated risk assessment frameworks. The days of perfunctory ingredient declarations are rapidly becoming obsolete, replaced by a more holistic and scientifically grounded approach to ingredient safety and transparency.Ingredient Traceability: Building a Transparent Supply Chain

The future of food manufacturing hinges on unprecedented levels of ingredient traceability. Regulatory bodies are developing comprehensive frameworks that will require manufacturers to implement end-to-end tracking systems, providing granular visibility into every stage of the production process. Advanced technologies like blockchain, Internet of Things (IoT) sensors, and sophisticated tracking algorithms will become standard tools for ensuring ingredient authenticity, origin, and safety. Manufacturers must view these requirements not as burdensome regulations but as opportunities to build consumer trust and demonstrate commitment to quality and transparency.Technological Innovation: The Cornerstone of Compliance

Successful navigation of these regulatory changes will demand significant technological investment. Manufacturers must embrace digital transformation, developing integrated systems that can seamlessly capture, analyze, and report complex production data. Artificial intelligence, machine learning, and advanced data analytics will become critical tools for maintaining compliance, predicting potential risks, and demonstrating proactive safety management. Companies that view technological innovation as a strategic imperative will be best positioned to thrive in this new regulatory environment.Strategic Adaptation: A Holistic Approach to Regulatory Compliance

The most successful food manufacturers will approach these regulatory changes as strategic opportunities rather than mere compliance challenges. This requires a cultural shift towards continuous improvement, scientific rigor, and unwavering commitment to consumer safety. Cross-functional collaboration, ongoing training, and a culture of innovation will be essential. Organizations must develop agile frameworks that can quickly adapt to emerging regulatory requirements while maintaining operational efficiency and product quality.RELATED NEWS

Companies

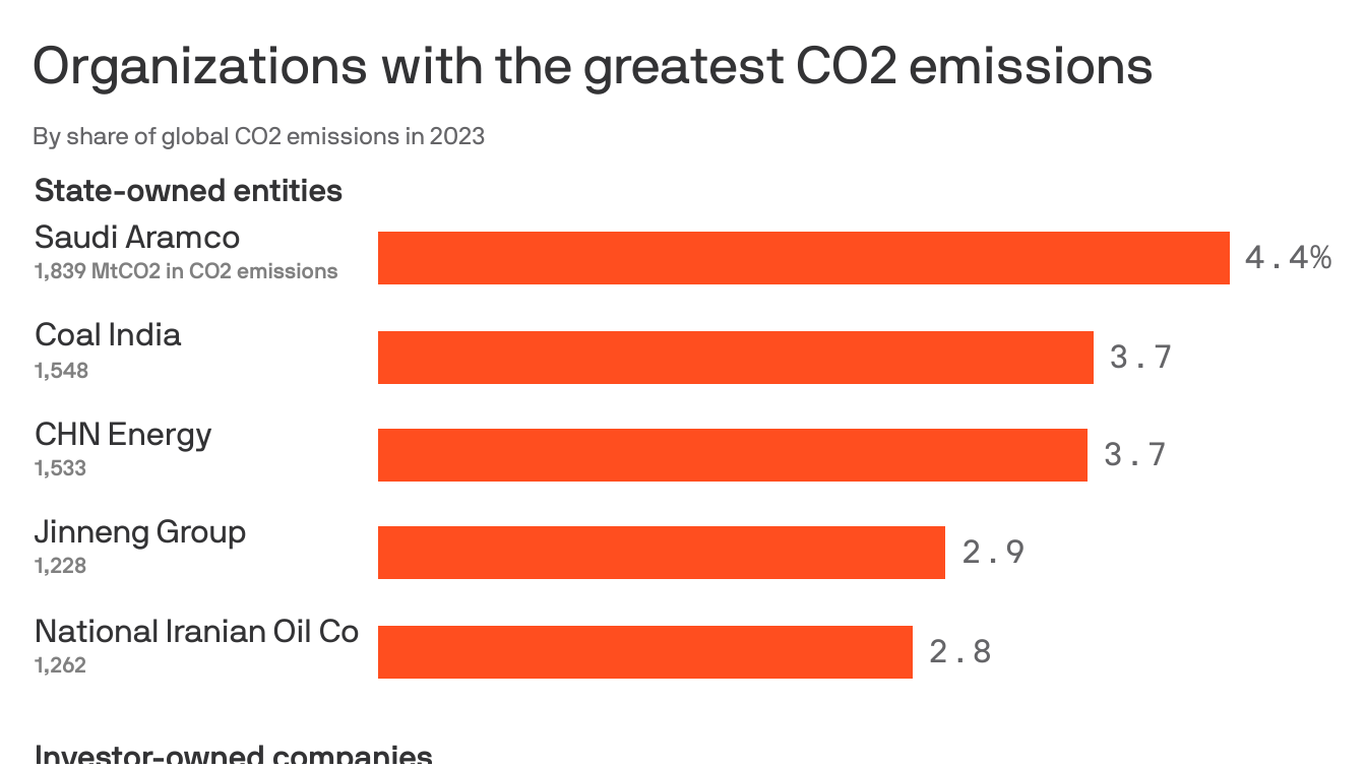

Climate Culprits Unveiled: The Corporate Giants Driving Global Carbon Chaos

2025-03-05 05:01:00

Companies

Breaking: NJ Transit Revolutionizes Mobility with Expanded Ride-Share Options for Disabled Commuters

2025-04-22 08:24:17

Companies

Shareholder Showdown: How Public Companies Dominate VICOM's Ownership Landscape

2025-03-03 02:41:56