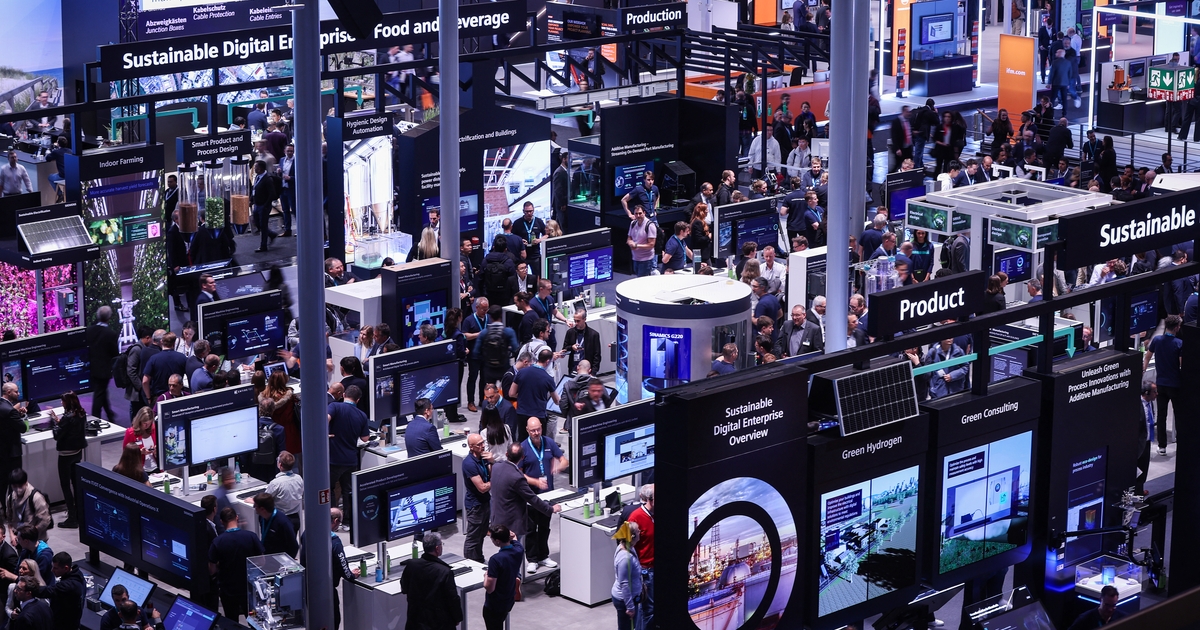

AI Transforms Factory Floors: Inside the Industrial Revolution at Hannover Messe 2025

Manufacturing

2025-04-15 10:54:37Content

The manufacturing landscape is undergoing a revolutionary transformation, driven by the powerful convergence of cloud computing, generative AI, and advanced robotics. This technological trinity is reshaping how industries design, produce, and optimize their manufacturing processes with unprecedented efficiency and innovation.

Cloud computing provides the expansive computational infrastructure that enables seamless data processing and storage. Generative AI brings intelligent design capabilities, capable of creating complex product blueprints and optimizing manufacturing workflows. Meanwhile, advanced robotics introduces precision, adaptability, and autonomous capabilities to production lines.

By integrating these technologies, manufacturers can now:

• Develop more sophisticated and intricate product designs

• Reduce production costs and minimize waste

• Enhance predictive maintenance strategies

• Create more flexible and responsive manufacturing environments

• Accelerate innovation cycles

As these technologies continue to evolve and intertwine, they promise to unlock new frontiers of manufacturing potential, driving industries toward a more intelligent, efficient, and adaptive future.

Industrial Revolution 4.0: How Emerging Technologies Are Reshaping Manufacturing's Future

In an era of unprecedented technological transformation, manufacturing stands at the precipice of a radical metamorphosis. The convergence of cutting-edge technologies is not just changing how we produce goods, but fundamentally reimagining the entire industrial landscape, promising unprecedented efficiency, innovation, and strategic capabilities.Revolutionizing Production: Where Technology Meets Manufacturing Genius

The Technological Convergence Phenomenon

The intersection of cloud computing, generative artificial intelligence, and advanced robotics represents more than a mere technological upgrade—it's a comprehensive industrial revolution. Manufacturers are no longer constrained by traditional production methodologies, instead embracing dynamic, intelligent systems that can adapt, learn, and optimize in real-time. Modern manufacturing environments are becoming increasingly sophisticated, with intelligent machines communicating seamlessly across complex networks. Cloud-based platforms enable unprecedented data integration, allowing manufacturers to create highly responsive, interconnected production ecosystems that can predict maintenance needs, optimize resource allocation, and dramatically reduce operational inefficiencies.Generative AI: The New Design Architect

Generative artificial intelligence is transforming product design and development processes with remarkable precision. By leveraging advanced algorithms and machine learning capabilities, AI can generate complex design iterations that human engineers might never conceive, pushing the boundaries of innovation and engineering possibilities. These intelligent systems analyze vast datasets, identifying optimal design configurations that balance performance, material efficiency, and manufacturing feasibility. Manufacturers can now explore design solutions that were previously unimaginable, reducing development cycles and creating products with enhanced functionality and reduced production costs.Robotic Intelligence: Precision Meets Adaptability

Advanced robotics are no longer confined to repetitive, mundane tasks. Modern robotic systems integrate sophisticated sensors, machine learning algorithms, and adaptive capabilities that enable them to perform intricate, nuanced operations with human-like precision and flexibility. These intelligent machines can dynamically adjust their movements, learn from environmental feedback, and collaborate seamlessly with human workers. The result is a manufacturing environment where automation and human expertise complement each other, driving unprecedented levels of productivity and innovation.Cloud Computing: The Invisible Infrastructure

Cloud computing serves as the critical backbone of this technological transformation, providing the computational power and data management capabilities necessary to support complex manufacturing ecosystems. By leveraging distributed computing resources, manufacturers can process massive datasets, run sophisticated simulations, and implement real-time monitoring systems. The cloud enables seamless global collaboration, allowing design teams, production managers, and supply chain experts to work together irrespective of geographical boundaries. This interconnectedness facilitates faster decision-making, more responsive production strategies, and enhanced global competitiveness.Economic and Strategic Implications

The convergence of these technologies represents more than a technological upgrade—it's a fundamental restructuring of industrial capabilities. Manufacturers who successfully integrate these technologies will gain significant competitive advantages, characterized by increased operational efficiency, reduced costs, and the ability to rapidly innovate. Small and medium enterprises can now access sophisticated technological capabilities that were previously available only to large corporations, democratizing industrial innovation and creating new opportunities for global economic participation.RELATED NEWS

Manufacturing

Manufacturing's AI Revolution: Inside the Game-Changing Conversations of Smart Manufacturing Week 2025

2025-03-17 10:37:36

Manufacturing

Driving the Future: GM's AI Revolution Accelerates Toward Autonomous Mobility

2025-03-13 10:15:13

Manufacturing

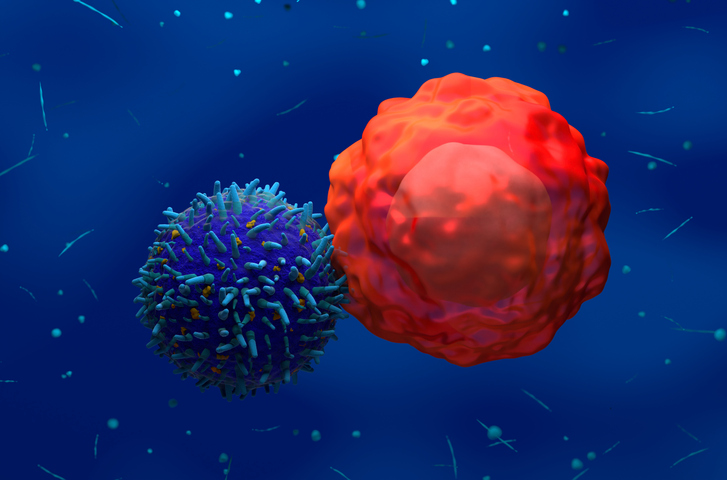

Revolutionary Tech Breakthrough: How Spectral Cytometry is Supercharging CAR T-Cell Therapy Manufacturing

2025-05-02 06:07:16