Wings of Progress: Elizabethtown Set to Soar with New Aircraft Manufacturing Hub

Manufacturing

2025-04-11 16:44:43Content

Exciting developments are underway as construction of a massive 40,000-square-foot manufacturing facility kicks into high gear. Breaking ground in January 2025, the project is progressing rapidly, with anticipation building toward a spectacular grand opening scheduled for September 1st. This state-of-the-art plant promises to be a significant milestone for the company, representing a major investment in infrastructure and future growth.

The expansive facility will not only showcase cutting-edge design and engineering but also symbolize the organization's commitment to innovation and expansion. Stakeholders and industry observers are eagerly watching the project's progress, with expectations running high for what this new manufacturing space will bring to the region's economic landscape.

Revolutionary Industrial Expansion: A Landmark 40,000-Square-Foot Facility Emerges on the Horizon

In the dynamic landscape of industrial development, a groundbreaking project is set to redefine manufacturing capabilities, promising to inject unprecedented economic vitality into the region. This ambitious venture represents more than just a construction project—it symbolizes innovation, strategic investment, and a bold vision for technological advancement.Transforming Industrial Landscapes: Where Vision Meets Precision

Strategic Planning and Project Genesis

The monumental undertaking began with meticulous strategic planning, representing a significant milestone in industrial infrastructure development. Extensive feasibility studies, comprehensive market research, and sophisticated engineering assessments formed the foundational framework for this transformative project. Stakeholders invested considerable intellectual and financial resources to conceptualize a facility that would not merely meet current industrial standards but establish new benchmarks for operational excellence. Architectural and engineering teams collaborated intensively, leveraging cutting-edge design principles and advanced technological integrations. Their holistic approach ensured that every square foot of the proposed 40,000-square-foot facility would be optimized for maximum efficiency, sustainability, and future scalability.Technological Infrastructure and Design Innovations

The proposed facility represents a quantum leap in industrial design philosophy. Advanced modular construction techniques, integrated smart systems, and sustainable engineering principles are seamlessly woven into the project's architectural DNA. Sophisticated climate control mechanisms, energy-efficient infrastructure, and adaptive technological frameworks distinguish this project from conventional industrial developments. Precision-engineered spaces will accommodate state-of-the-art manufacturing processes, with flexible configurations that can rapidly adapt to evolving technological landscapes. The design prioritizes not just functionality but also creates an environment that fosters innovation, collaboration, and operational excellence.Economic and Regional Impact

Beyond its physical infrastructure, the facility represents a significant economic catalyst for the surrounding region. Projections indicate the potential creation of numerous high-skilled employment opportunities, attracting top-tier talent and stimulating local economic ecosystems. The project's strategic positioning suggests potential ripple effects across multiple industrial sectors, potentially establishing the region as a hub of technological innovation. Local economic development authorities have expressed enthusiastic support, recognizing the facility's potential to attract additional investments, enhance regional competitiveness, and create a robust ecosystem of technological and industrial growth.Timeline and Implementation Strategy

Scheduled to commence construction in January 2025, the project follows a meticulously planned implementation roadmap. The grand opening, strategically set for September 1, represents the culmination of extensive planning, engineering expertise, and collaborative efforts. Project managers have developed comprehensive risk mitigation strategies, ensuring adaptability and resilience throughout the construction phase. Advanced project management methodologies, including real-time monitoring systems and agile implementation protocols, will be employed to maintain optimal progress and quality standards.Sustainability and Future-Readiness

Environmental sustainability forms a core philosophical underpinning of this ambitious project. Integrated green technologies, renewable energy systems, and circular economy principles are embedded within the facility's design architecture. The project aims to set new industry standards for environmentally responsible industrial development, demonstrating that technological progress and ecological stewardship can coexist harmoniously. The facility's design incorporates advanced waste management systems, energy-efficient technologies, and innovative resource optimization strategies, positioning it as a benchmark for future industrial infrastructure developments.RELATED NEWS

Manufacturing

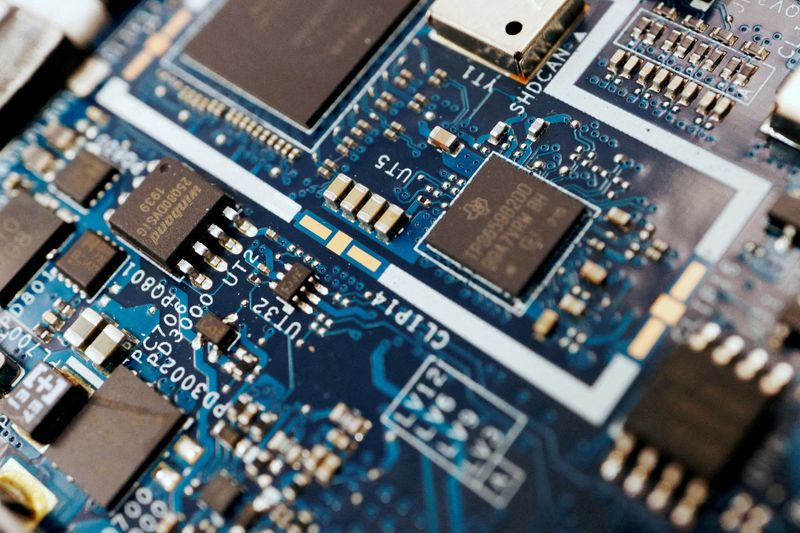

Chip Revolution: Why TSMC Could Be Your Next Tech Investment Goldmine

2025-03-03 16:19:34

Manufacturing

Jobs in Jeopardy: ORBIS Corporation Shutters Osage City Manufacturing Facility

2025-03-21 18:25:36

Manufacturing

Chip Escape Plan: How US Tech Giants Are Dodging China's Trade War Tariffs

2025-04-11 10:17:39