Factory Floor Revolt: How Trump's Trade Promises Unravel in Real-World Business

Manufacturing

2025-04-10 16:38:50Content

When President Donald Trump announced his intention to reshape American trade policy through tariffs and reinvigorate domestic manufacturing, Evita Chu, a resourceful entrepreneur, immediately sprang into action. Determined to explore local alternatives, she began making a series of strategic phone calls to investigate potential yarn suppliers within the United States, seeking to reduce her reliance on international sources from China and Europe.

Chu's proactive approach reflects a growing sentiment among small business owners who are carefully navigating the complex landscape of international trade and domestic production. Her quick response to the president's trade statements demonstrates the agility and adaptability required in today's rapidly changing economic environment.

By exploring domestic yarn sourcing, Chu not only potentially supports local manufacturers but also positions her business to be more resilient in the face of shifting trade policies and global economic uncertainties. Her initiative represents a microcosm of how American entrepreneurs are responding to significant changes in trade strategy and manufacturing dynamics.

Trade Tensions: How Trump's Tariff Policies Spark a Manufacturing Revolution

In the complex landscape of global trade, presidential decisions can trigger profound ripple effects that reshape entire industrial ecosystems. The intersection of political strategy and economic policy creates dynamic challenges for entrepreneurs navigating an increasingly interconnected global marketplace.Transforming Global Supply Chains Through Strategic Economic Maneuvers

The Tariff Landscape: Reimagining American Manufacturing

The Trump administration's aggressive trade policies represented a seismic shift in economic strategy, compelling businesses to reevaluate their international sourcing methodologies. Entrepreneurs like Evita Chu found themselves at a critical crossroads, forced to explore domestic manufacturing alternatives that could potentially mitigate the economic uncertainties introduced by international trade tensions. Manufacturers and business leaders confronted unprecedented challenges as traditional global supply chains faced potential disruption. The strategic implementation of tariffs created a complex ecosystem where adaptability became the primary currency of survival. Companies were compelled to develop innovative sourcing strategies that balanced cost-effectiveness with geopolitical risk management.Domestic Production: A Strategic Imperative

The push towards domestic manufacturing emerged as a multifaceted response to international trade complexities. Entrepreneurs discovered that reshoring production capabilities offered more than just economic advantages—it represented a fundamental reimagining of industrial infrastructure. By investigating local production networks, businesses uncovered hidden opportunities for innovation and efficiency. The transition wasn't merely about replacing international suppliers but about building more resilient, flexible manufacturing ecosystems that could withstand global economic fluctuations.Economic Resilience in a Volatile Global Market

Navigating the intricate landscape of international trade required sophisticated strategic thinking. Businesses needed to develop comprehensive approaches that balanced immediate economic considerations with long-term sustainability goals. The tariff policies introduced unprecedented complexity into global supply chain management. Entrepreneurs like Chu were required to develop nuanced strategies that could rapidly adapt to changing economic landscapes. This meant cultivating robust domestic networks, investing in local manufacturing capabilities, and maintaining flexibility in sourcing methodologies.Technological Innovation and Manufacturing Transformation

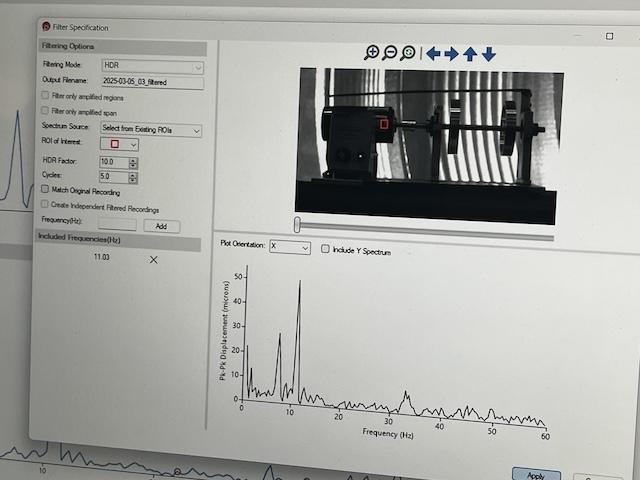

The economic pressures created by tariff policies accelerated technological innovation within the manufacturing sector. Companies were incentivized to explore advanced production techniques, automation technologies, and more efficient manufacturing processes. This technological renaissance represented more than an economic adaptation—it signaled a fundamental reimagining of American industrial capabilities. Entrepreneurs discovered that domestic production could offer competitive advantages beyond mere cost considerations, including enhanced quality control, faster market responsiveness, and greater supply chain transparency.The Human Element of Economic Transformation

Behind the complex economic strategies and policy implementations were human stories of adaptation and resilience. Entrepreneurs like Evita Chu embodied the innovative spirit necessary to navigate rapidly changing economic landscapes. Their experiences highlighted the profound interconnectedness of global trade policies, demonstrating how macroeconomic decisions could fundamentally reshape individual business strategies. The ability to pivot, innovate, and reimagine traditional approaches became the defining characteristic of successful modern enterprises.RELATED NEWS

Manufacturing

Robots Revolution: How AI is Transforming the Future of Manufacturing

2025-03-14 04:02:19

Manufacturing

Beyond Employment: Why Manufacturing's True Mission Isn't About Job Creation

2025-04-27 07:00:00

Manufacturing

Cyber Siege: Masimo's Production Paralyzed by Sophisticated Digital Assault

2025-05-06 21:00:00