Tariff Tremors: Local Car Parts Maker Reveals the Hidden Cost of Vehicle Repairs

Manufacturing

2025-04-07 21:45:00Content

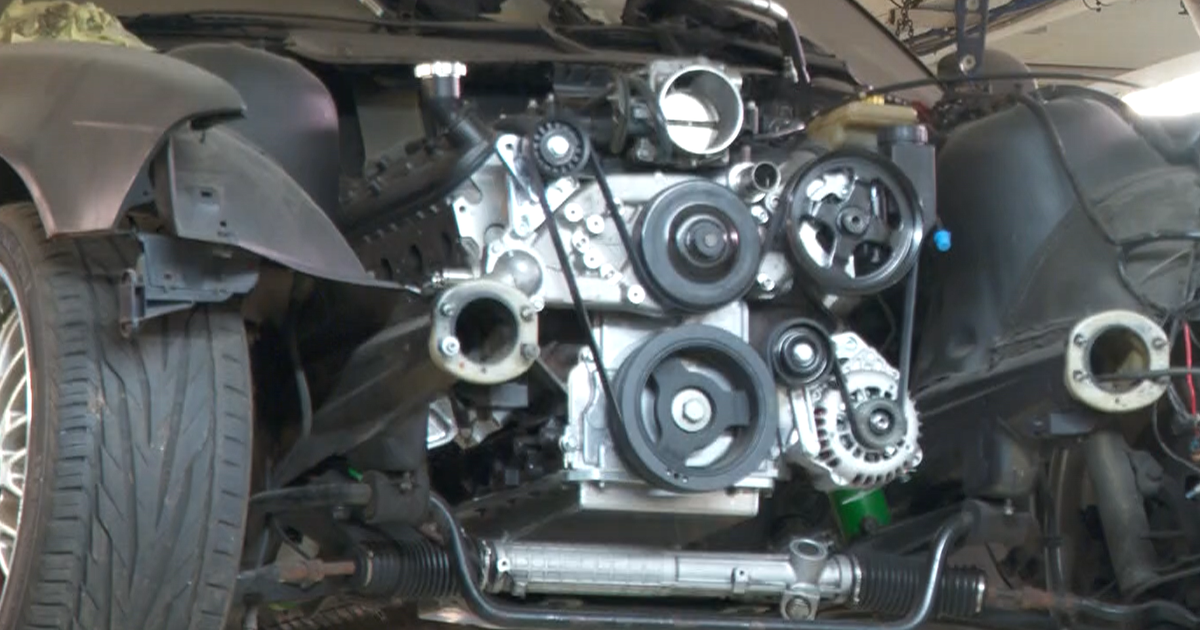

As economic uncertainties loom, a Maryland-based automotive parts manufacturer is proactively strategizing to navigate potential financial challenges that could impact its customer base. The company is taking strategic steps to mitigate potential economic pressures, demonstrating resilience and forward-thinking leadership in a volatile market landscape.

By anticipating potential financial constraints, the manufacturer is positioning itself to provide stability and support to its clients during potentially turbulent economic times. Their preparedness reflects a commitment to maintaining robust supply chains and ensuring continued reliability in the automotive parts industry.

The company's proactive approach includes carefully analyzing market trends, optimizing operational efficiency, and developing flexible strategies to cushion against potential economic downturns. This strategic planning underscores their dedication to maintaining competitive advantage and supporting their customers through uncertain economic conditions.

Manufacturing Resilience: Navigating Economic Turbulence in Automotive Supply Chains

In the intricate landscape of automotive manufacturing, companies are increasingly confronting unprecedented economic challenges that demand strategic adaptation and innovative problem-solving. The delicate balance between operational efficiency and financial sustainability has never been more critical, particularly for regional manufacturers seeking to maintain competitive edge in a volatile global marketplace.Transforming Challenges into Opportunities in Automotive Manufacturing

Economic Pressures and Strategic Positioning

The automotive parts manufacturing sector stands at a critical crossroads, where traditional business models are being systematically dismantled and reconstructed. Maryland-based manufacturers are experiencing unprecedented economic pressures that require sophisticated strategic repositioning. Complex market dynamics, including supply chain disruptions, fluctuating raw material costs, and technological transformations, are compelling companies to develop robust, adaptive frameworks. Financial resilience demands more than conventional cost-cutting measures. Manufacturers must integrate advanced technological solutions, optimize operational workflows, and develop comprehensive risk mitigation strategies. This approach involves leveraging data analytics, implementing predictive maintenance protocols, and creating flexible production infrastructures that can rapidly respond to market fluctuations.Technological Innovation as a Competitive Advantage

Emerging technological paradigms are revolutionizing automotive parts manufacturing. Advanced manufacturing technologies like artificial intelligence, machine learning, and Internet of Things (IoT) integration are providing unprecedented opportunities for operational optimization. Companies investing in these transformative technologies can significantly enhance production efficiency, reduce operational costs, and create more responsive manufacturing ecosystems. Sophisticated sensor technologies and real-time monitoring systems enable manufacturers to predict potential equipment failures, streamline maintenance processes, and minimize unexpected production interruptions. By embracing these innovative approaches, manufacturers can develop more resilient and adaptable operational models that transcend traditional industry limitations.Supply Chain Dynamics and Strategic Adaptation

The contemporary automotive manufacturing landscape demands a holistic approach to supply chain management. Manufacturers must develop intricate, interconnected networks that can withstand global economic uncertainties. This requires developing strategic partnerships, diversifying supplier bases, and implementing advanced risk management protocols. Geopolitical tensions, trade regulations, and global economic shifts necessitate a more nuanced approach to supply chain architecture. Successful manufacturers will be those who can create flexible, responsive systems capable of rapidly adjusting to changing market conditions while maintaining consistent quality and performance standards.Workforce Development and Human Capital

Human capital represents a critical component of manufacturing resilience. Companies must invest in comprehensive workforce training programs that equip employees with advanced technological skills and adaptive problem-solving capabilities. This involves creating continuous learning environments that encourage innovation, technological literacy, and cross-functional collaboration. By developing robust talent development strategies, manufacturers can create internal ecosystems that foster creativity, technological proficiency, and organizational agility. This approach not only enhances operational capabilities but also creates more engaged, motivated workforce communities.Financial Strategy and Risk Mitigation

Navigating economic uncertainties requires sophisticated financial strategies that balance risk management with strategic investment. Manufacturers must develop comprehensive financial models that account for potential market disruptions, technological investments, and operational transformations. Implementing advanced financial forecasting tools, maintaining flexible capital allocation strategies, and developing comprehensive contingency plans are essential for maintaining organizational resilience. This approach enables companies to transform potential challenges into strategic opportunities for growth and innovation.RELATED NEWS

Manufacturing

Reshoring Roulette: Nike's Bold Gamble to Bring Manufacturing Back Home

2025-05-03 00:00:00

Manufacturing

Trade Tensions Spark Medical Manufacturing Shift: Therma Bright Weighs Continental Relocation

2025-04-16 10:30:00

Manufacturing

Trade War Fallout: How Tariffs Are Silently Taxing American Consumers

2025-04-14 00:14:00