Sole Survivors: How China Maintains Its Grip on Global Footwear Production

Manufacturing

2025-04-07 20:28:09Content

In a candid assessment of the current manufacturing landscape, Xero cofounder Lena Phoenix argues that reshoring footwear production to the United States faces significant challenges. Her statement highlights the complex economic realities that make domestic manufacturing of shoes increasingly difficult in today's global market.

Phoenix's insights underscore the intricate web of global supply chains, manufacturing expertise, and cost considerations that currently make it impractical to completely relocate footwear production back to American soil. The statement reflects the broader challenges faced by companies seeking to bring manufacturing jobs back to the United States, particularly in labor-intensive industries like footwear.

The Global Footwear Manufacturing Dilemma: Why U.S. Production Remains a Distant Dream

In the complex landscape of global manufacturing, the footwear industry stands as a testament to intricate international economic dynamics. The challenges of reshoring production to the United States reveal a multifaceted narrative of economic constraints, global supply chains, and competitive market forces that continue to shape the manufacturing ecosystem.Unraveling the Complex Threads of Footwear Production Challenges

The Economic Landscape of Global Manufacturing

The footwear industry represents a microcosm of broader manufacturing challenges facing the United States. Decades of globalization have fundamentally transformed production strategies, creating an intricate web of international manufacturing relationships that cannot be easily dismantled. Multinational corporations have invested billions in establishing sophisticated supply chains across countries like Vietnam, China, and Indonesia, where labor costs remain significantly lower than domestic alternatives. Economic analyses reveal that the cost of manufacturing shoes in the United States would require substantial infrastructure investments and fundamental restructuring of existing production models. The current global manufacturing ecosystem has optimized production processes to such an extent that domestic reproduction would demand unprecedented economic recalibration.Technological and Infrastructure Barriers

Modern footwear manufacturing demands highly specialized equipment and technological infrastructure that cannot be rapidly reconstructed within U.S. borders. The specialized machinery, precision engineering, and intricate supply chain networks have been meticulously developed in countries with established manufacturing ecosystems. Companies like Xero have recognized the profound challenges inherent in attempting to repatriate manufacturing. The technological gap between current international production capabilities and potential domestic alternatives represents a significant barrier that extends far beyond simple economic calculations.Labor Market Complexities

The American labor market presents unique challenges for large-scale footwear manufacturing. Skilled workers trained in specialized manufacturing techniques are increasingly scarce, while wage expectations significantly exceed those in traditional manufacturing regions. This labor dynamic creates additional complexity in considering domestic production strategies. Workforce development would require massive educational and training investments, potentially spanning decades, to recreate the manufacturing expertise currently concentrated in international production centers. The human capital required for such a transformation represents a substantial and potentially prohibitive investment.Global Competitive Dynamics

International trade agreements, tariff structures, and complex economic relationships further complicate the potential for domestic footwear production. The current global economic framework has been carefully constructed to optimize manufacturing efficiency, with intricate interdependencies that cannot be easily restructured. Multinational corporations have developed sophisticated risk management strategies that leverage international manufacturing capabilities. These strategies incorporate complex considerations including labor costs, technological capabilities, regulatory environments, and geopolitical stability.Sustainable Manufacturing Considerations

While reshoring discussions often focus on economic metrics, contemporary manufacturing must also consider environmental sustainability. International production centers have increasingly invested in green manufacturing technologies, creating additional layers of complexity in potential domestic production strategies. The environmental footprint of potential U.S. manufacturing would require comprehensive evaluation, considering everything from energy consumption to material sourcing and transportation logistics. These multifaceted considerations extend far beyond simple economic calculations.Future Outlook and Strategic Implications

The future of footwear manufacturing will likely involve continued global collaboration rather than complete domestic reconstruction. Hybrid models incorporating advanced technologies, strategic international partnerships, and innovative production techniques may emerge as more realistic alternatives to traditional reshoring narratives. Technological innovations like advanced robotics, artificial intelligence, and sophisticated supply chain management tools could potentially reshape manufacturing landscapes, offering new possibilities for domestic and international production strategies.RELATED NEWS

Manufacturing

Strategic Shift: Biopharma Developer Severs Ties with Contract Manufacturing Partner

2025-03-24 06:45:20

Manufacturing

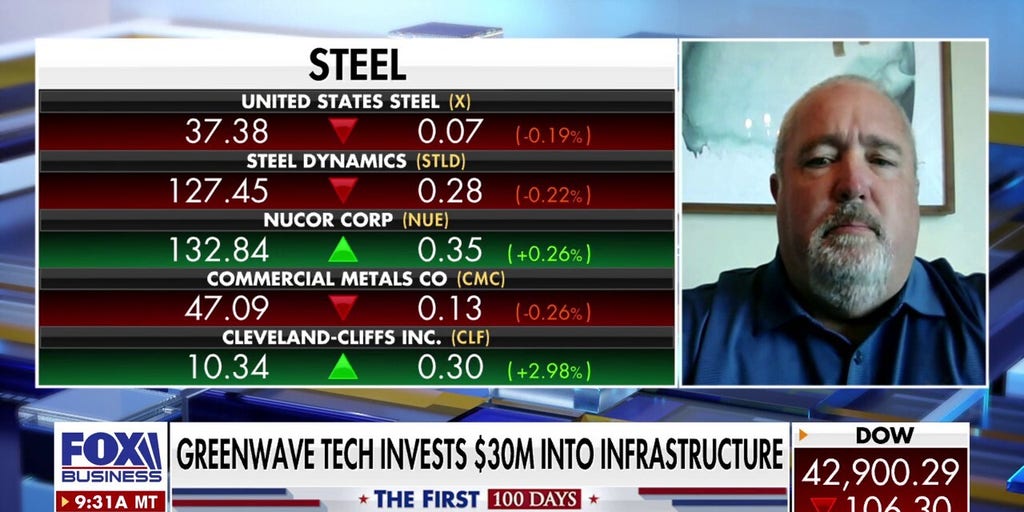

Steel's Comeback: How Trump's Tariffs Are Leveling the Industrial Battlefield

2025-03-06 17:36:50

Manufacturing

Iowa Speedway Revs Up: Sukup Manufacturing Drives into INDYCAR Sponsorship

2025-04-10 16:30:53