Soaring Innovation: How Connecticut's New Simulation Hub is Revolutionizing Engineering

Manufacturing

2025-04-07 07:15:17Content

Driving Innovation: How CMSC Elevates Aero Gear's Aerospace Excellence

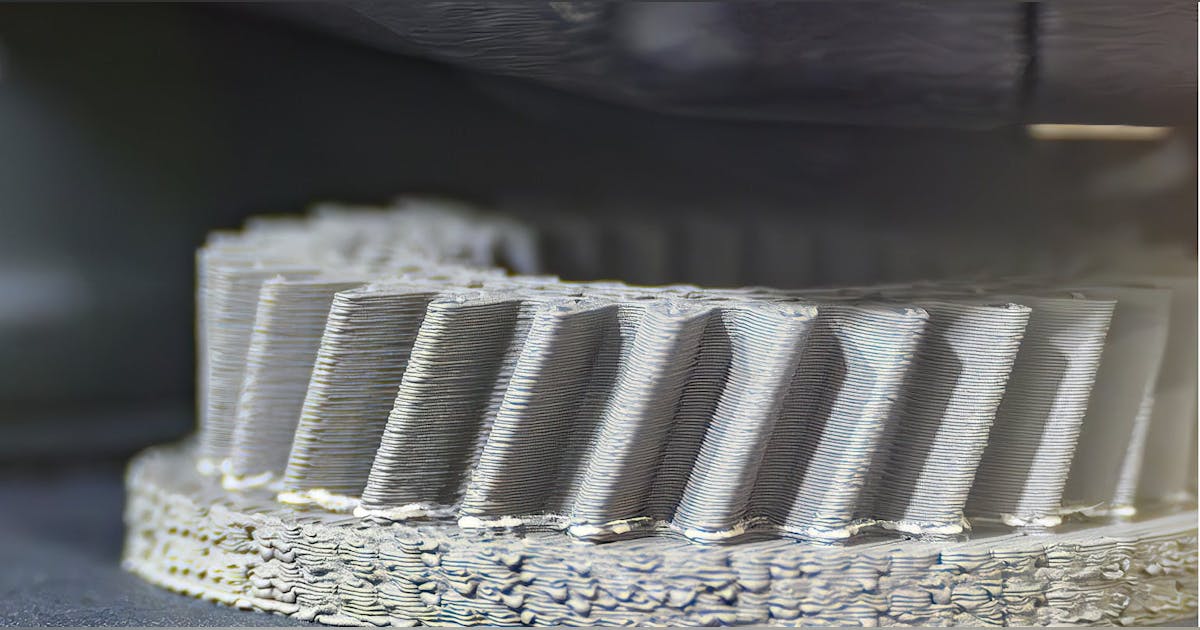

In the dynamic world of aerospace engineering, Connecticut-based Aero Gear stands as a testament to precision and innovation, with the Connecticut Manufacturing Simulation Center (CMSC) playing a pivotal role in their success. Through collaborative expertise and cutting-edge modeling techniques, CMSC has become an instrumental partner in helping Aero Gear refine their manufacturing processes and push the boundaries of aerospace technology.

By leveraging advanced simulation technologies and deep technical knowledge, CMSC provides Aero Gear with sophisticated modeling solutions that enhance product design, optimize manufacturing efficiency, and ensure the highest standards of quality and performance. Their partnership exemplifies how strategic technical support can transform a local manufacturing company into a leader in the competitive aerospace industry.

The collaboration between CMSC and Aero Gear demonstrates the power of technical innovation, showcasing how targeted simulation and modeling can drive excellence in advanced manufacturing. Together, they are not just creating components, but engineering the future of aerospace technology.

Revolutionizing Aerospace: How CMSC Transforms Innovation at Aero Gear

In the dynamic world of aerospace engineering, collaboration stands as the cornerstone of technological advancement. The partnership between Connecticut's innovative aerospace company Aero Gear and cutting-edge research institutions represents a pivotal moment in industrial innovation, showcasing how strategic alliances can propel technological boundaries beyond traditional limitations.Pioneering Excellence in Aerospace Engineering

The Strategic Partnership Landscape

The collaboration between CMSC and Aero Gear emerges as a testament to the transformative power of interdisciplinary research and development. By bridging academic expertise with industrial innovation, this partnership creates a unique ecosystem where technological boundaries are continuously challenged and redefined. Advanced computational modeling techniques developed by CMSC provide Aero Gear with unprecedented insights into complex aerospace engineering challenges, enabling more sophisticated design methodologies and performance optimization strategies. Sophisticated simulation technologies allow engineers to explore intricate mechanical interactions and aerodynamic principles with remarkable precision. These computational models simulate extreme operational conditions, revealing potential design vulnerabilities and performance limitations before physical prototyping, thereby dramatically reducing development costs and accelerating innovation cycles.Computational Modeling: A Game-Changing Approach

Computational modeling represents a revolutionary approach to aerospace engineering, transcending traditional design methodologies. By leveraging advanced algorithms and high-performance computing infrastructure, researchers can generate complex simulations that capture nuanced mechanical interactions with extraordinary accuracy. These digital representations enable engineers to experiment with multiple design configurations, test hypothetical scenarios, and optimize component performance without substantial physical infrastructure investments. The integration of machine learning algorithms further enhances these computational capabilities, allowing predictive models to learn from historical data and generate increasingly sophisticated design recommendations. This approach not only accelerates innovation but also introduces a level of precision previously unattainable through conventional engineering practices.Technological Innovation and Industry Transformation

The collaboration between CMSC and Aero Gear exemplifies a broader trend of academic-industrial partnerships driving technological innovation. By combining academic research capabilities with industrial engineering expertise, these partnerships create powerful synergies that accelerate technological development across multiple domains. Advanced computational techniques enable engineers to explore complex design challenges with unprecedented depth and sophistication. Machine learning algorithms, integrated with high-performance computing systems, generate insights that challenge traditional engineering paradigms, opening new frontiers of technological possibility.Future Implications and Technological Potential

The ongoing partnership between CMSC and Aero Gear signals a promising trajectory for aerospace engineering innovation. As computational modeling techniques continue to evolve, the potential for groundbreaking technological advancements becomes increasingly tangible. These collaborative efforts not only push the boundaries of current technological capabilities but also establish new frameworks for interdisciplinary research and development. By embracing computational complexity and leveraging advanced simulation technologies, researchers and engineers can explore previously unimaginable design possibilities. The convergence of academic research and industrial engineering expertise creates a dynamic environment where innovation thrives, promising transformative developments in aerospace technology.RELATED NEWS

Manufacturing

Soaring Ambitions: Aerospace Titan Unveils Billion-Dollar Manufacturing Boost for American Industry

2025-03-13 12:39:48

Manufacturing

Tech Showdown: Nano Dimension Faces Ultimatum in High-Stakes Merger Battle

2025-03-26 00:00:00

Manufacturing

Made in America: NEMA's Bold New Certification Breathes Life into U.S. Manufacturing

2025-04-30 12:00:00