Forging Tomorrow: How Smart Factories Are Revolutionizing Global Production

Manufacturing

2025-04-03 20:53:12Content

The Future of Manufacturing: Transformative Trends Reshaping Industry in 2025

As we stand on the cusp of a technological revolution, advanced manufacturing is undergoing a profound metamorphosis. The convergence of cutting-edge technologies and strategic innovations is redefining how products are designed, produced, and delivered.

Automation and Artificial Intelligence: The New Manufacturing Backbone

Intelligent robotics and AI are no longer futuristic concepts but present-day realities. Manufacturers are increasingly deploying smart systems that can predict maintenance needs, optimize production workflows, and dramatically reduce human error. Machine learning algorithms now analyze complex data streams in real-time, enabling unprecedented precision and efficiency.

Sustainability: Beyond Green Initiatives

Sustainability has evolved from a corporate buzzword to a fundamental business strategy. Manufacturers are embracing circular economy principles, developing zero-waste production processes, and investing in renewable energy technologies. From recycled materials to energy-efficient manufacturing techniques, sustainability is becoming a competitive advantage.

Supply Chain Revolution

The global pandemic exposed vulnerabilities in traditional supply chains, prompting a radical rethinking of logistics and procurement. Advanced manufacturers are now implementing resilient, digitally-integrated supply networks that can rapidly adapt to disruptions, leveraging technologies like blockchain and IoT for enhanced transparency and real-time tracking.

Digital Twin Technology: Simulating Success

Digital twin technology is transforming product development and manufacturing processes. By creating virtual replicas of physical systems, manufacturers can simulate scenarios, predict performance, and optimize designs before physical production, significantly reducing costs and time-to-market.

As we move deeper into 2025, these interconnected trends are not just reshaping manufacturing—they're redefining what's possible in industrial innovation.

Revolutionary Manufacturing Metamorphosis: Navigating the Technological Frontier of 2025

In the rapidly evolving landscape of industrial innovation, manufacturers are standing at the precipice of a transformative era. The convergence of cutting-edge technologies, sustainability imperatives, and strategic reimagining is reshaping the manufacturing ecosystem, promising unprecedented opportunities and challenges that will redefine industrial productivity and global competitiveness.Pioneering the Next Industrial Revolution: Where Technology Meets Possibility

Automation's Quantum Leap: Intelligent Systems Redefining Production Paradigms

The manufacturing sector is experiencing an unprecedented technological renaissance, where automation transcends traditional mechanical processes. Advanced robotic systems now integrate sophisticated artificial intelligence, enabling unprecedented levels of precision, adaptability, and autonomous decision-making. Machine learning algorithms continuously optimize production workflows, predicting maintenance requirements, minimizing downtime, and dramatically enhancing operational efficiency. Manufacturers are deploying collaborative robots, or cobots, that seamlessly interact with human workers, creating hybrid workspaces where technological capabilities complement human creativity and problem-solving skills. These intelligent systems can analyze complex production scenarios in milliseconds, making real-time adjustments that were inconceivable just a few years ago.Artificial Intelligence: The Cognitive Backbone of Modern Manufacturing

Artificial intelligence has emerged as the transformative catalyst revolutionizing manufacturing strategies. Advanced neural networks and predictive analytics are enabling unprecedented insights into production processes, supply chain dynamics, and market demands. Machine learning models can now forecast potential disruptions, optimize resource allocation, and generate sophisticated scenario planning with remarkable accuracy. AI-driven quality control systems utilize computer vision and deep learning algorithms to detect microscopic defects imperceptible to human inspectors. These technologies not only ensure superior product quality but also significantly reduce waste and improve overall manufacturing precision. By integrating predictive maintenance protocols, manufacturers can anticipate equipment failures before they occur, minimizing costly interruptions and extending machinery lifecycle.Sustainability: Engineering an Environmentally Conscious Manufacturing Future

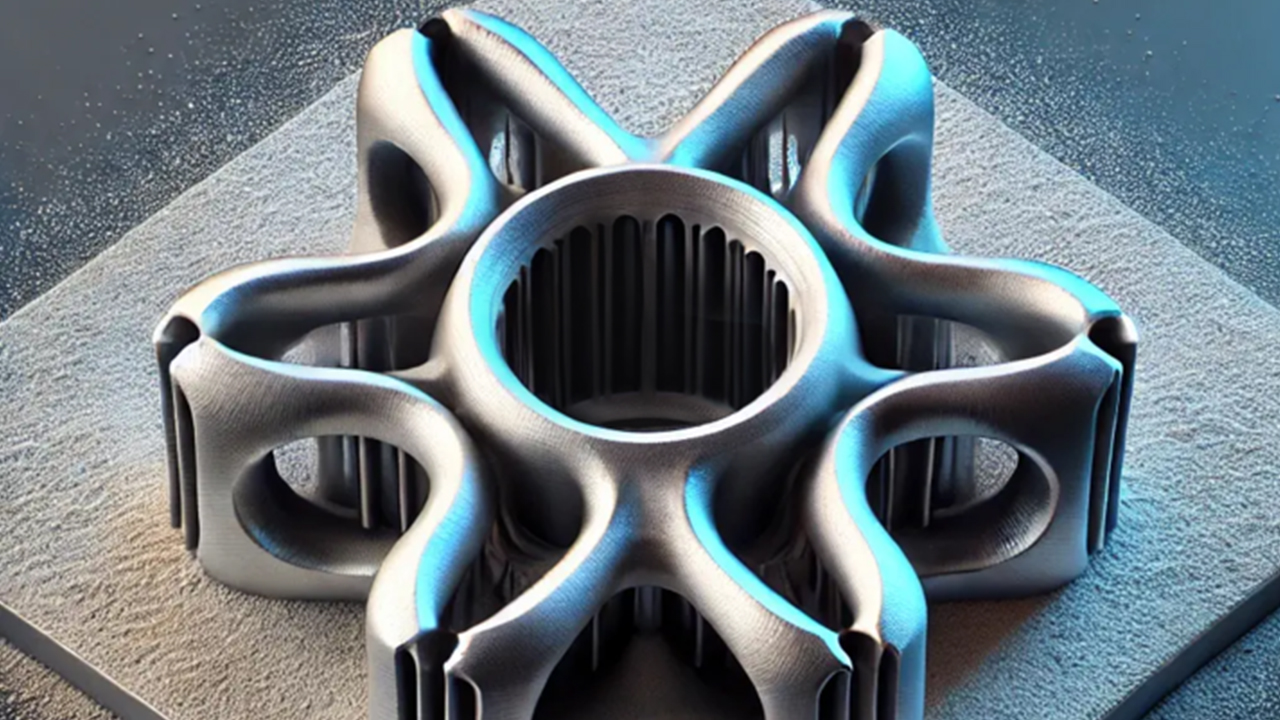

Environmental sustainability has transitioned from a peripheral consideration to a core strategic imperative in modern manufacturing. Companies are implementing comprehensive green technologies that minimize carbon footprints, optimize resource consumption, and develop circular economy models. Advanced manufacturing techniques now prioritize renewable energy integration, waste reduction, and sustainable material sourcing. Innovative manufacturers are developing closed-loop production systems that dramatically reduce environmental impact. By reimagining traditional linear production models, these approaches enable material recycling, energy recovery, and minimal waste generation. Cutting-edge technologies like 3D printing and advanced material sciences are facilitating more sustainable manufacturing processes, allowing companies to achieve ambitious environmental targets while maintaining competitive economic performance.Supply Chain Resilience: Navigating Global Complexity with Technological Precision

The global manufacturing landscape demands unprecedented levels of supply chain adaptability and technological integration. Advanced digital platforms and blockchain technologies are revolutionizing transparency, traceability, and risk management across complex international networks. Real-time tracking, predictive analytics, and decentralized verification systems are enabling manufacturers to build more robust, flexible, and responsive supply chain ecosystems. Manufacturers are developing sophisticated digital twin technologies that create comprehensive virtual replicas of physical supply chains. These advanced simulation environments allow companies to model potential disruptions, test strategic interventions, and optimize logistical networks with extraordinary precision. By leveraging artificial intelligence and machine learning, organizations can now anticipate and mitigate potential challenges before they materialize.Human-Centric Technology: Empowering Workforce Transformation

The future of manufacturing is fundamentally human-centric, recognizing that technological advancement must complement and elevate human potential. Advanced training programs, augmented reality interfaces, and skill development platforms are enabling workers to seamlessly integrate with increasingly sophisticated technological environments. Manufacturers are investing heavily in upskilling initiatives, creating learning ecosystems that prepare workers for emerging technological roles. By fostering a culture of continuous learning and technological adaptability, companies are building resilient, innovative workforces capable of navigating complex technological landscapes.RELATED NEWS

Manufacturing

Tariff Triumph: How Trump's Trade War Sparked a Toy Manufacturing Renaissance in America

2025-03-25 19:00:32

Manufacturing

Forging the Future: Siemens and Michigan Unite to Revolutionize Metal 3D Printing Education

2025-02-24 16:23:46