Pocket-Sized Production: How a Miniature Factory is Revolutionizing Hands-On Learning

Manufacturing

2025-04-03 20:55:00Content

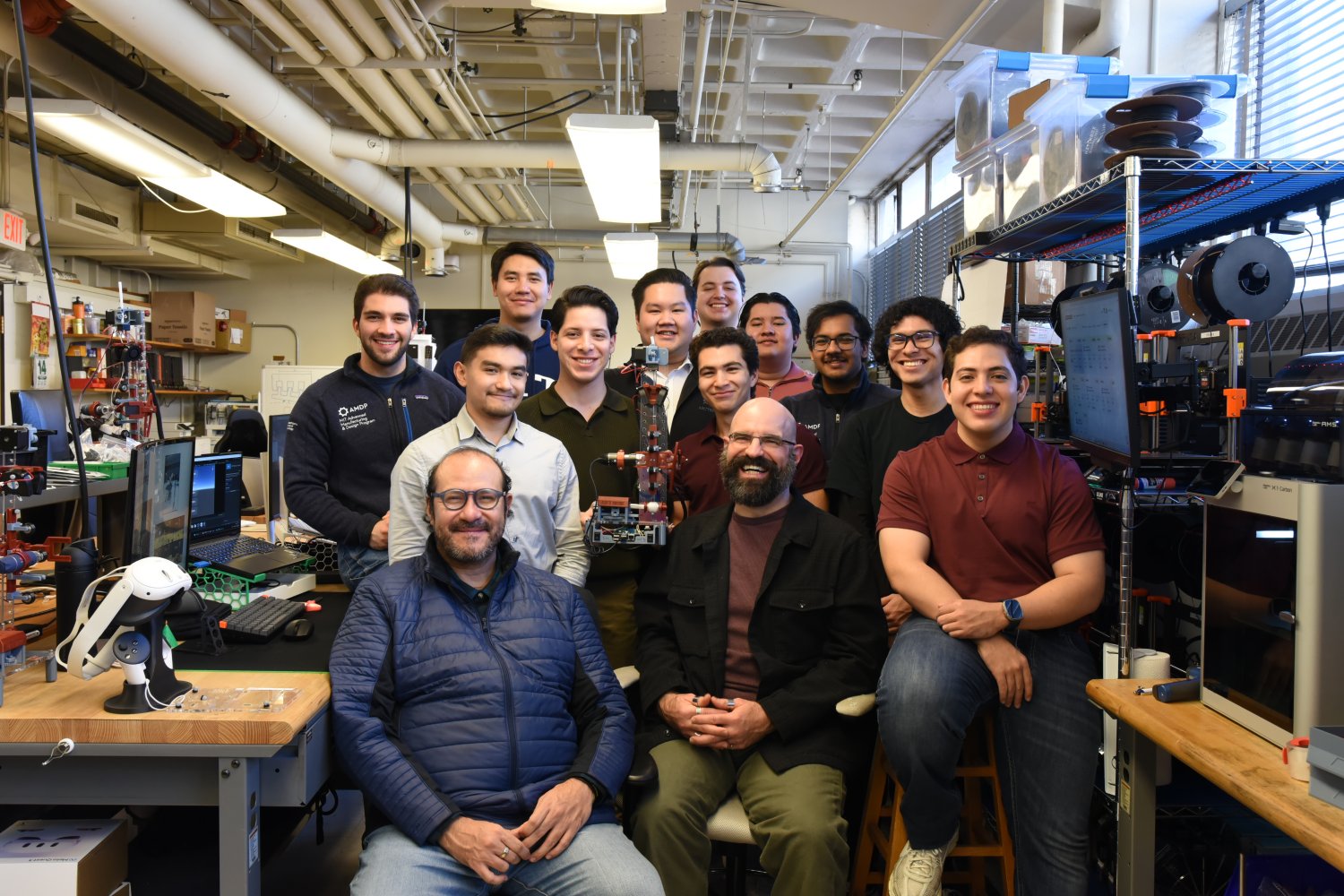

In an innovative collaboration bridging technology and education, undergraduate students from Tecnológico de Monterrey are pioneering groundbreaking research alongside their MIT counterparts. Their ambitious project focuses on developing affordable, desktop-sized fiber-extrusion devices, known as FrEDs, within the dynamic learning environment of the FrED Factory.

These young innovators are pushing the boundaries of manufacturing technology by creating low-cost, compact machines that could revolutionize how small-scale fabrication is approached. By working directly in a hands-on laboratory setting, the students are gaining invaluable practical experience while simultaneously advancing technological solutions that could have far-reaching implications for makers, researchers, and small-scale manufacturers.

The collaborative effort highlights the power of cross-institutional learning and the potential of emerging engineering talent to drive technological innovation from the ground up. Through this immersive "in-the-lab" teaching approach, students are transforming theoretical knowledge into tangible, practical solutions that could reshape future manufacturing processes.

Revolutionizing Manufacturing: Student Innovators Craft Groundbreaking Desktop Fiber Extrusion Technology

In the rapidly evolving landscape of technological innovation, a remarkable collaboration between Tecnológico de Monterrey and MIT is pushing the boundaries of manufacturing design, showcasing how young minds can transform industrial processes through creative engineering and collaborative research.Pioneering the Future of Low-Cost Manufacturing Solutions

The Genesis of Collaborative Innovation

The intersection of academic brilliance and technological ambition has given birth to an extraordinary project that promises to reshape manufacturing paradigms. Seven undergraduate students from Tecnológico de Monterrey have embarked on a groundbreaking journey, developing sophisticated methods for creating low-cost, desktop fiber-extrusion devices within the innovative environment of the FrED Factory at MIT. These young engineers are not merely students but visionary creators challenging traditional manufacturing constraints. By focusing on developing compact, affordable fiber-extrusion devices, they are addressing critical challenges in industrial production methodologies, demonstrating that transformative technological solutions can emerge from collaborative academic environments.Technological Architecture of Fiber-Extrusion Devices

The desktop fiber-extrusion devices, abbreviated as FrEDs, represent a paradigm shift in manufacturing technology. Unlike conventional large-scale industrial machinery, these compact devices offer unprecedented flexibility and accessibility. By miniaturizing complex manufacturing processes, the student innovators are democratizing technological capabilities, enabling smaller organizations and research institutions to access advanced production techniques. The intricate design of these devices involves sophisticated engineering principles, integrating precision mechanics, material science, and computational modeling. Each FrED prototype represents a delicate balance between cost-effectiveness and technological sophistication, requiring meticulous attention to material properties, thermal dynamics, and mechanical tolerances.Collaborative Learning and Technological Advancement

The "in-the-lab" teaching approach employed at the FrED Factory transcends traditional educational models. By immersing students in real-world problem-solving environments, MIT and Tecnológico de Monterrey are cultivating a new generation of interdisciplinary engineers capable of addressing complex technological challenges. This collaborative framework allows students to transform theoretical knowledge into practical innovations, bridging academic research with industrial applications. The hands-on experience provides invaluable insights into the intricate processes of technological development, from conceptualization to prototype creation.Potential Impact and Future Implications

The development of low-cost, desktop fiber-extrusion devices carries profound implications across multiple industries. From advanced manufacturing and research laboratories to educational institutions and small-scale production facilities, these innovative devices could democratize access to sophisticated manufacturing technologies. By reducing financial barriers and technical complexity, the student-led project opens new horizons for technological experimentation and innovation. The potential applications span diverse domains, including prototype development, materials research, educational demonstrations, and small-batch manufacturing processes.Bridging Academic Excellence and Technological Innovation

The collaboration between Tecnológico de Monterrey and MIT exemplifies the transformative power of international academic partnerships. By creating an environment that encourages cross-cultural knowledge exchange and collaborative problem-solving, these institutions are nurturing a global ecosystem of technological innovation. The FrED Factory serves as a microcosm of future educational and research models, where students are not passive recipients of knowledge but active creators of technological solutions that can reshape industrial landscapes.RELATED NEWS

Manufacturing

High-Tech Manufacturing Boom: Visionary Developer Targets Kettering's Innovation Hub

2025-04-23 10:00:00

Manufacturing

Strategic Maritime Move: China Merchants Industry Seizes Shipbuilding Opportunity with Qingdao Yangfan Acquisition

2025-04-14 06:07:54

Manufacturing

Robotic Revolution: Fanuc Unveils Cutting-Edge Manufacturing Marvels at Tech Showcase

2025-04-27 12:51:26