Breaking Barriers: How Smart Manufacturers Are Revolutionizing Workplace Inclusivity

Manufacturing

2025-04-03 19:50:01Content

Manufacturing Success: Navigating Industry Challenges with Expert Insights

In an illuminating episode of the popular podcast "Manufacturing Success," host Mike Carrouth sits down with Colin P. Calvert, a seasoned Partner from the Irvine office of Fisher Phillips. The dynamic conversation delves deep into the complex landscape of manufacturing challenges, offering listeners a comprehensive and insightful exploration of the industry's most pressing issues.

Calvert brings his extensive legal and strategic expertise to the table, providing a nuanced perspective on the obstacles facing modern manufacturers. From regulatory hurdles to workforce dynamics, the discussion promises to unpack the intricate challenges that businesses in the manufacturing sector must navigate to remain competitive and innovative.

Listeners can expect a rich, informative dialogue that not only highlights the difficulties but also offers practical strategies and forward-thinking solutions for manufacturers looking to thrive in today's rapidly evolving business environment.

Navigating the Manufacturing Landscape: Insights from Industry Experts

In the dynamic world of manufacturing, success is not just about machinery and production lines, but about understanding the intricate challenges that shape the industry's future. As businesses strive to remain competitive, innovative strategies and expert insights become crucial navigational tools in an ever-evolving economic landscape.Unlocking Manufacturing Potential: Where Strategy Meets Innovation

The Evolving Manufacturing Ecosystem

Manufacturing today is a complex tapestry of technological innovation, strategic planning, and human expertise. Companies are no longer simply producing goods; they are creating comprehensive ecosystems that integrate advanced technologies, sustainable practices, and adaptive workforce strategies. The traditional manufacturing model has been fundamentally transformed, requiring leaders to reimagine their approach to production, talent management, and market responsiveness. Modern manufacturers must navigate a multifaceted environment where digital transformation, automation, and global supply chain dynamics intersect. This requires a holistic understanding of technological trends, economic shifts, and emerging workforce capabilities. Successful organizations are those that can rapidly adapt, leverage cutting-edge technologies, and develop resilient operational frameworks.Technological Disruption and Strategic Adaptation

The manufacturing sector is experiencing unprecedented technological disruption. Artificial intelligence, machine learning, Internet of Things (IoT), and advanced robotics are reshaping production methodologies. These technologies are not merely tools but fundamental reimaginings of how manufacturing processes can be conceptualized and executed. Companies that successfully integrate these technologies gain significant competitive advantages. They can optimize production efficiency, reduce operational costs, enhance product quality, and create more responsive supply chains. However, technological integration is not just about purchasing advanced equipment; it requires a comprehensive strategy that includes workforce training, cultural transformation, and continuous learning environments.Workforce Development and Human Capital

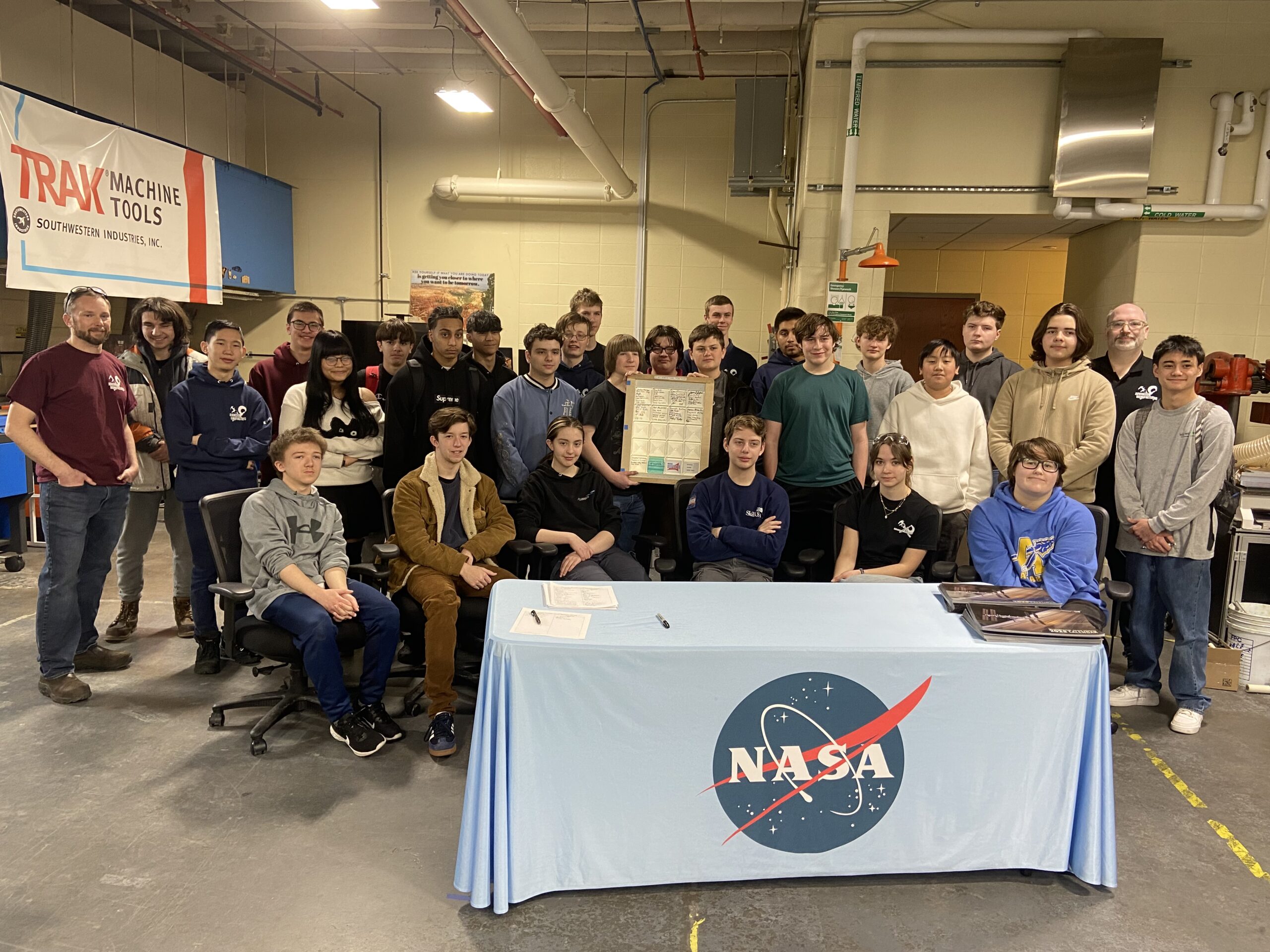

The human element remains paramount in manufacturing's technological revolution. As automation increases, the role of human workers becomes more strategic and sophisticated. Manufacturers must invest in comprehensive training programs that equip employees with advanced digital skills, critical thinking capabilities, and adaptive problem-solving techniques. Successful workforce development strategies go beyond traditional training models. They involve creating learning ecosystems that encourage continuous skill enhancement, cross-functional collaboration, and innovation-driven mindsets. Companies must develop flexible talent management approaches that can quickly respond to technological changes and emerging skill requirements.Sustainable Manufacturing Practices

Sustainability has transitioned from a peripheral consideration to a core strategic imperative in manufacturing. Organizations are increasingly recognizing that environmental responsibility is not just an ethical choice but a competitive necessity. This involves implementing circular economy principles, reducing carbon footprints, and developing more resource-efficient production methodologies. Sustainable manufacturing encompasses a holistic approach that considers environmental impact, social responsibility, and economic viability. Companies are investing in renewable energy technologies, developing recyclable product designs, and creating closed-loop manufacturing systems that minimize waste and maximize resource utilization.Global Supply Chain Resilience

Recent global disruptions have highlighted the critical importance of supply chain resilience. Manufacturers must develop sophisticated, adaptable supply chain strategies that can withstand unexpected challenges. This involves diversifying supplier networks, implementing advanced risk management technologies, and creating more transparent, flexible logistics frameworks. Strategic supply chain management now requires real-time data analytics, predictive modeling, and agile decision-making capabilities. Companies are investing in technologies that provide comprehensive visibility across global supply networks, enabling more proactive and responsive operational strategies.RELATED NEWS

Inside the Crackdown: Manufacturers' Survival Guide to ICE Immigration Enforcement

Automotive Veteran Gerald Johnson Joins Group14's Board, Bringing GM's Manufacturing Expertise to Battery Tech Innovator