Breaking Boundaries: How AI Transforms Learning, Problem-Solving, and Continuous Evolution

Manufacturing

2025-04-03 16:00:00Content

Driving Manufacturing Success Through Learning and Innovation

In today's rapidly evolving industrial landscape, advanced manufacturing stands at the crossroads of technological innovation and strategic transformation. Companies that embrace continuous learning and breakthrough innovations are not just surviving—they're setting new benchmarks for excellence and competitiveness.

The Power of Continuous Learning

Modern manufacturing is no longer about repetitive processes, but about adaptive intelligence. Organizations that invest in upskilling their workforce create a dynamic ecosystem where employees are empowered to think creatively, solve complex challenges, and drive technological advancements.

Innovation as a Strategic Imperative

Innovation isn't just a buzzword—it's the lifeblood of advanced manufacturing. By fostering a culture that encourages experimentation, risk-taking, and collaborative problem-solving, companies can unlock unprecedented opportunities for growth and differentiation.

Key Strategies for Success

- Implement robust training and development programs

- Encourage cross-functional collaboration

- Invest in cutting-edge technologies

- Create an environment that rewards creative thinking

By prioritizing learning and innovation, manufacturers can transform challenges into opportunities, staying ahead in an increasingly competitive global marketplace.

Revolutionizing Manufacturing: The Transformative Power of Continuous Learning and Innovation

In the rapidly evolving landscape of advanced manufacturing, organizations face unprecedented challenges and opportunities that demand a radical reimagining of traditional approaches. The competitive edge no longer belongs to those with the most resources, but to those who can most effectively adapt, learn, and innovate in real-time.Unlock Your Manufacturing Potential: Where Knowledge Meets Cutting-Edge Technology

The Paradigm Shift in Manufacturing Capabilities

Modern manufacturing is experiencing a profound transformation driven by technological disruption and global economic dynamics. Companies that once relied on static operational models are now discovering that survival hinges on their ability to cultivate a culture of continuous learning and technological adaptation. This isn't merely about acquiring new machinery or implementing incremental improvements, but fundamentally reimagining how human potential intersects with technological innovation. The most successful manufacturers are those who view their workforce as dynamic intellectual capital, capable of evolving alongside emerging technologies. They invest not just in equipment, but in creating ecosystems of learning that empower employees to become active participants in technological advancement.Strategic Learning Frameworks in Advanced Manufacturing

Developing comprehensive learning strategies requires a multifaceted approach that transcends traditional training methodologies. Organizations must create immersive learning environments that blend theoretical knowledge with practical, hands-on experiences. This means developing robust internal training programs, establishing partnerships with educational institutions, and creating mentorship frameworks that facilitate knowledge transfer across generational and technological boundaries. Advanced manufacturers are increasingly leveraging technologies like augmented reality, simulation-based training, and adaptive learning platforms to create personalized educational experiences. These technologies allow for real-time skill assessment, targeted learning interventions, and the ability to rapidly upskill workforces in response to emerging technological trends.Technological Innovation as a Competitive Imperative

Innovation in manufacturing is no longer optional—it's existential. Companies must develop robust innovation ecosystems that encourage experimentation, tolerate calculated risks, and provide structured pathways for transforming creative ideas into tangible technological solutions. This requires breaking down traditional organizational silos, fostering cross-functional collaboration, and creating mechanisms that reward creative problem-solving. Successful organizations are implementing innovation labs, establishing venture capital arms focused on emerging technologies, and creating internal platforms that allow employees at all levels to contribute to technological development. By democratizing innovation, these companies are tapping into the collective intelligence of their entire workforce.The Human-Technology Symbiosis

The future of manufacturing lies not in replacing human workers with technology, but in creating symbiotic relationships where human creativity and technological capabilities amplify each other. Advanced manufacturers are developing collaborative robotics systems, implementing AI-driven predictive maintenance, and creating adaptive manufacturing environments that can dynamically reconfigure based on real-time data insights. This approach requires a fundamental reimagining of workforce development, where technical skills are complemented by critical thinking, emotional intelligence, and the ability to work seamlessly with advanced technological systems. The most valuable employees will be those who can bridge the gap between human intuition and machine precision.Global Competitiveness and Continuous Learning

In an increasingly interconnected global economy, manufacturers must view continuous learning as a strategic imperative for maintaining competitive advantage. This means developing agile learning infrastructures that can rapidly respond to technological shifts, geopolitical changes, and emerging market demands. Organizations must cultivate global learning networks, leverage international partnerships, and create knowledge exchange platforms that allow for rapid skill and technological transfer across geographical boundaries. The ability to learn faster and more effectively than competitors has become the ultimate differentiator in advanced manufacturing.RELATED NEWS

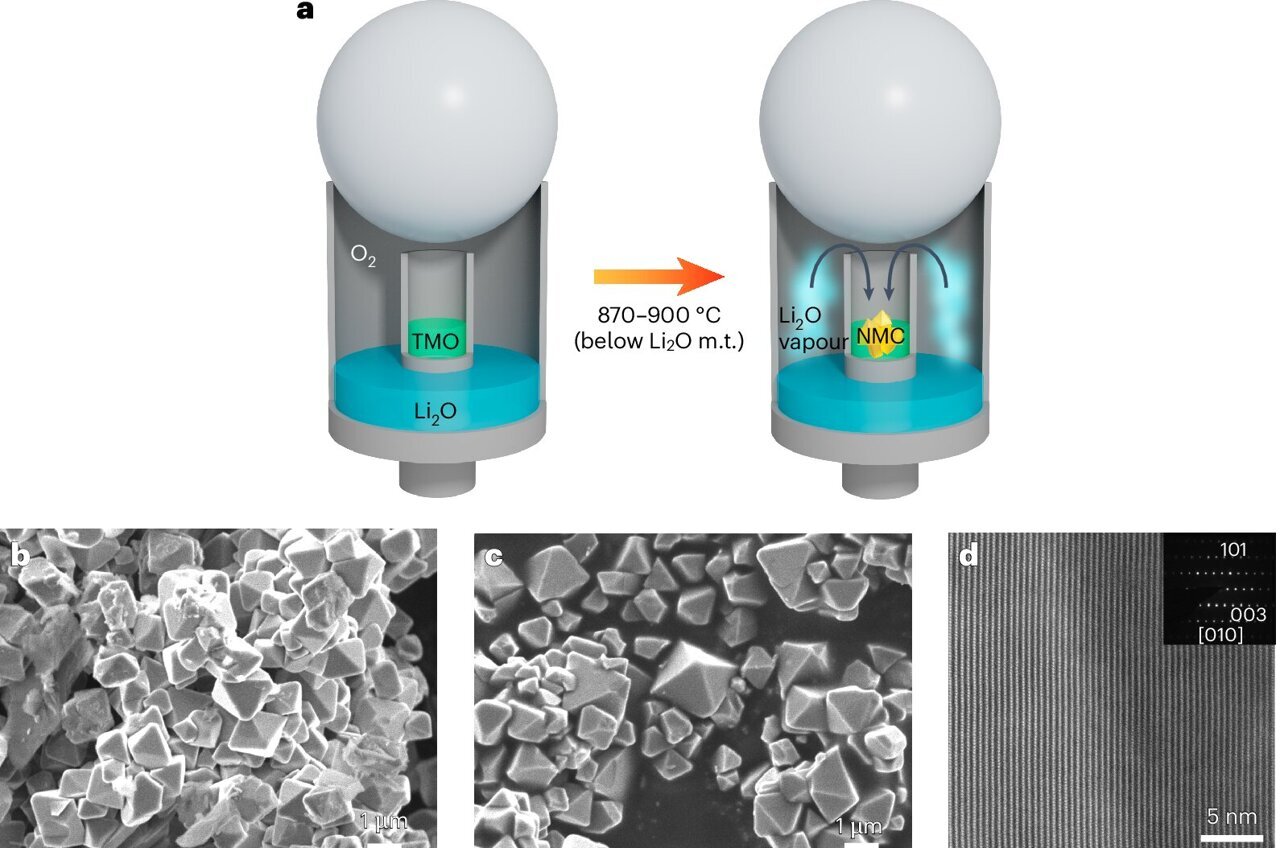

Battery Revolution: How Lithium Oxide Sublimation Could Slash Production Costs