Made in America: The High-Stakes Balancing Act Between Savings and Self-Reliance

Manufacturing

2025-04-01 10:00:00Content

In the wake of global supply chain disruptions, Marcel Botha, CEO of 10XBeta, is championing a critical conversation about the future of medical device manufacturing in South Africa. His insights shed light on the delicate balance between economic prudence and strategic national capability.

Botha recognizes the complex challenge facing the medical technology sector: how to maintain cost-effectiveness while simultaneously building robust domestic manufacturing infrastructure. The COVID-19 pandemic dramatically exposed vulnerabilities in global medical supply chains, underscoring the importance of local production capabilities.

"We're not just talking about saving money," Botha explains, "but about creating a resilient ecosystem that can respond quickly to national health emergencies." His approach advocates for a nuanced strategy that doesn't simply chase the lowest price point, but instead invests in local expertise, technology, and manufacturing capacity.

By prioritizing domestic manufacturing of essential medical devices, South Africa can reduce dependency on international suppliers, create local jobs, and develop critical technological capabilities. Botha's vision represents a forward-thinking approach that balances economic constraints with long-term strategic national interests.

As healthcare technology continues to evolve, leaders like Botha are proving that smart, strategic investment in local manufacturing can be both economically sound and nationally transformative.

Revolutionizing Medical Device Manufacturing: A Strategic Balancing Act

In the complex landscape of medical technology and manufacturing, leaders are constantly navigating the intricate challenges of cost-efficiency and domestic production capabilities. The medical device industry stands at a critical crossroads, where strategic decision-making can fundamentally transform healthcare infrastructure and economic resilience.Transforming Healthcare Manufacturing with Innovative Strategies

The Economic Imperative of Domestic Medical Device Production

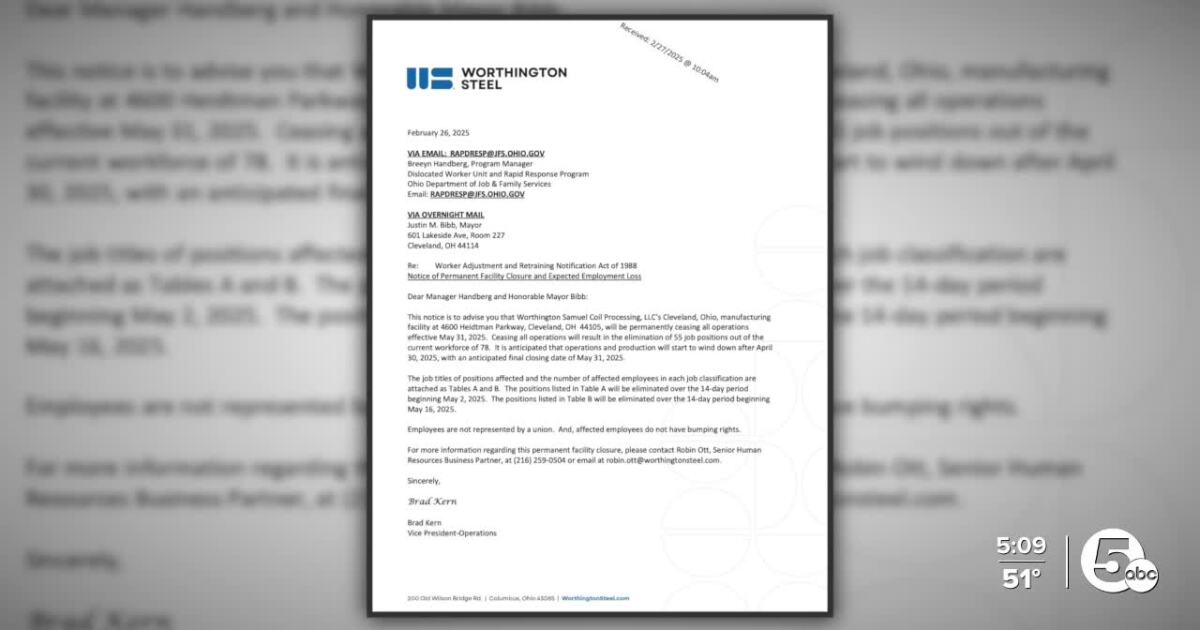

The global healthcare landscape has undergone unprecedented transformation in recent years, revealing critical vulnerabilities in international supply chains. Domestic manufacturing emerges as a strategic solution, offering multiple layers of economic and technological advantages. By localizing production, nations can mitigate risks associated with global disruptions, create high-skilled employment opportunities, and develop technological capabilities that extend far beyond immediate medical device requirements. Developing robust domestic manufacturing ecosystems requires substantial investment in infrastructure, workforce training, and technological innovation. Companies must balance immediate financial constraints with long-term strategic vision, understanding that short-term cost considerations can potentially compromise future technological capabilities and national healthcare security.Technological Innovation and Manufacturing Resilience

Advanced manufacturing technologies are revolutionizing medical device production, enabling more sophisticated, precise, and cost-effective manufacturing processes. Technologies like additive manufacturing, artificial intelligence-driven quality control, and advanced robotics are transforming traditional manufacturing paradigms. These technological interventions allow manufacturers to reduce production costs while simultaneously enhancing product quality and customization capabilities. By integrating cutting-edge technologies, domestic manufacturers can compete globally, creating value-added products that meet increasingly complex healthcare requirements.Strategic Cost Management in Medical Device Manufacturing

Cost efficiency remains a critical consideration for medical device manufacturers. However, the traditional approach of minimizing expenses must evolve into a more nuanced strategy that considers long-term value creation. This involves investing in scalable technologies, developing skilled workforce capabilities, and creating flexible manufacturing ecosystems that can rapidly adapt to changing market demands. Successful organizations recognize that cost management is not about reducing expenses but optimizing resource allocation. By strategically investing in research and development, workforce training, and advanced manufacturing technologies, companies can create sustainable competitive advantages that transcend traditional cost-cutting methodologies.Navigating Regulatory Landscapes and Global Competitiveness

Medical device manufacturing operates within complex regulatory environments that demand rigorous compliance and continuous innovation. Domestic manufacturers must develop sophisticated quality management systems that meet international standards while maintaining competitive pricing structures. This requires a holistic approach that integrates regulatory expertise, technological innovation, and strategic financial management. Companies must cultivate a culture of continuous learning and adaptation, ensuring their manufacturing capabilities remain at the forefront of global healthcare technology developments.Future-Proofing Medical Device Manufacturing

The future of medical device manufacturing lies in creating adaptable, technologically advanced, and economically sustainable production ecosystems. This demands a multidisciplinary approach that combines engineering expertise, financial acumen, and strategic vision. By embracing complexity and viewing manufacturing as a dynamic, evolving discipline, organizations can transform potential challenges into opportunities for innovation and growth. The most successful manufacturers will be those who can seamlessly integrate technological sophistication with strategic economic thinking.RELATED NEWS

Manufacturing

Silver Surge: How Companies Are Reinventing Workplace Strategy for an Aging Workforce

2025-04-09 00:00:00

Manufacturing

Manufacturing Momentum: China's Economic Pulse Strengthens Amid Global Trade Tensions

2025-03-03 01:56:07

Manufacturing

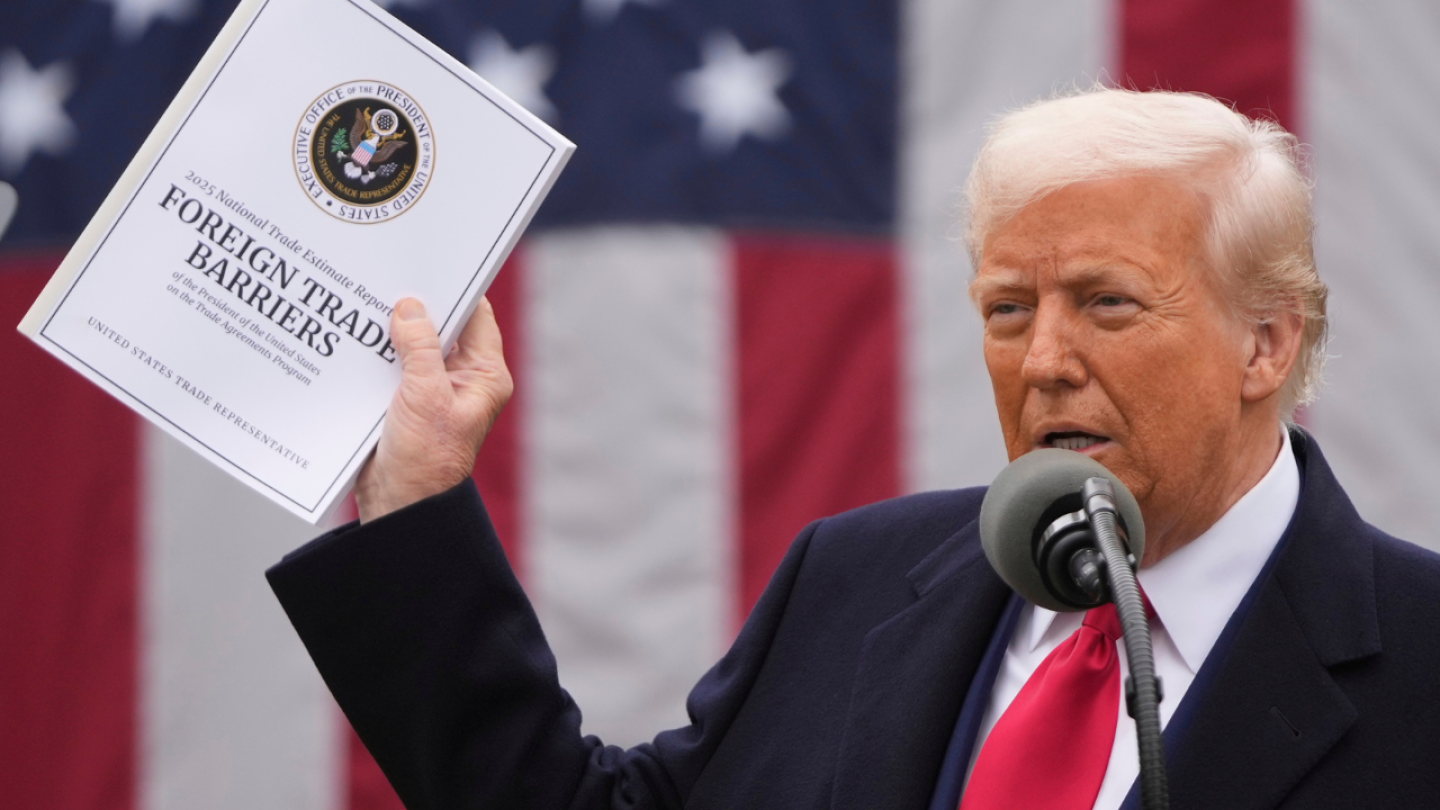

Trade War Redux: Trump's Bold Plan to Supercharge American Manufacturing with Retaliatory Tariffs

2025-04-02 20:58:31