Tariffs Loom, But Automatic Precision Stays Resilient: Inside the Company's Bold Manufacturing Strategy

Manufacturing

2025-03-29 11:00:00Content

At the heart of precision engineering, our company stands as a leader in crafting meticulously designed Swiss-quality components. We specialize in creating high-performance electrical connectors and contacts that push the boundaries of technical excellence. Our expertise spans a diverse range of premium metallic materials, including aluminum, brass, copper, and bronze, each carefully selected to meet the most demanding technical specifications.

Our commitment to precision is evident in every component we produce, reflecting the renowned Swiss tradition of engineering excellence. From intricate electrical contacts to sophisticated connectors, we transform raw metals into sophisticated, reliable solutions that power industries worldwide. Each piece is a testament to our dedication to quality, innovation, and technical mastery.

Precision Engineering: The Art of Crafting High-Performance Electrical Contacts

In the intricate world of advanced manufacturing, where precision meets innovation, a remarkable company stands at the forefront of electrical component engineering. Their mastery of metalworking transforms raw materials into sophisticated connectors that power countless technological marvels across global industries.Pioneering Precision: Where Engineering Meets Excellence

The Metallurgical Mastery of Electrical Connectivity

Modern manufacturing represents a complex dance of scientific expertise and technological innovation. At the heart of this intricate process lies the sophisticated creation of electrical contacts and connectors that serve as critical infrastructure for numerous technological systems. The company's approach transcends traditional manufacturing, embracing a holistic methodology that combines Swiss precision engineering with advanced metallurgical techniques. The production process begins with meticulous material selection, where aluminum, brass, copper, and bronze are carefully evaluated for their unique electromagnetic and structural properties. Each metal undergoes rigorous testing and analysis, ensuring that the final components meet exacting international standards of performance and reliability.Engineering Challenges in Precision Component Manufacturing

Developing high-performance electrical contacts requires an extraordinary blend of scientific knowledge and practical engineering skills. Manufacturers must navigate complex challenges, including thermal conductivity, electrical resistance, and mechanical durability. The intricate process involves understanding how different metal compositions interact under various environmental conditions. Sophisticated computer-aided design (CAD) technologies enable engineers to model and simulate component behaviors before physical production. This digital approach allows for unprecedented levels of precision, reducing material waste and optimizing manufacturing efficiency. Advanced computational tools help predict potential performance limitations and structural weaknesses, enabling proactive design modifications.Material Science and Technological Innovation

The selection of metals like copper and brass represents more than a simple material choice—it's a strategic decision rooted in deep material science understanding. Copper's exceptional electrical conductivity makes it ideal for high-performance electrical contacts, while brass offers remarkable corrosion resistance and mechanical strength. Modern manufacturing techniques, including precision machining and micro-fabrication, allow for the creation of components with tolerances measured in micrometers. These techniques demand extraordinary skill, sophisticated equipment, and a profound understanding of metallurgical principles. Each component becomes a testament to human engineering capability, representing the pinnacle of technological craftsmanship.Global Impact and Industrial Applications

The electrical contacts and connectors produced through these advanced manufacturing processes find applications across diverse sectors. From aerospace and telecommunications to renewable energy and medical technologies, these precision-engineered components form the invisible infrastructure supporting modern technological ecosystems. The company's commitment to quality extends beyond mere production, encompassing comprehensive research and development initiatives. Continuous innovation ensures that their electrical contacts remain at the cutting edge of technological advancement, meeting and often exceeding the evolving demands of global industries.Sustainability and Future-Oriented Manufacturing

Contemporary manufacturing increasingly emphasizes sustainability, and this company is no exception. By optimizing material usage, implementing energy-efficient production processes, and developing recyclable components, they demonstrate a forward-thinking approach to industrial production. The integration of sustainable practices with high-precision engineering represents a holistic vision of modern manufacturing—one that balances technological excellence with environmental responsibility. Each electrical contact becomes not just a functional component but a symbol of responsible, innovative engineering.RELATED NEWS

Manufacturing

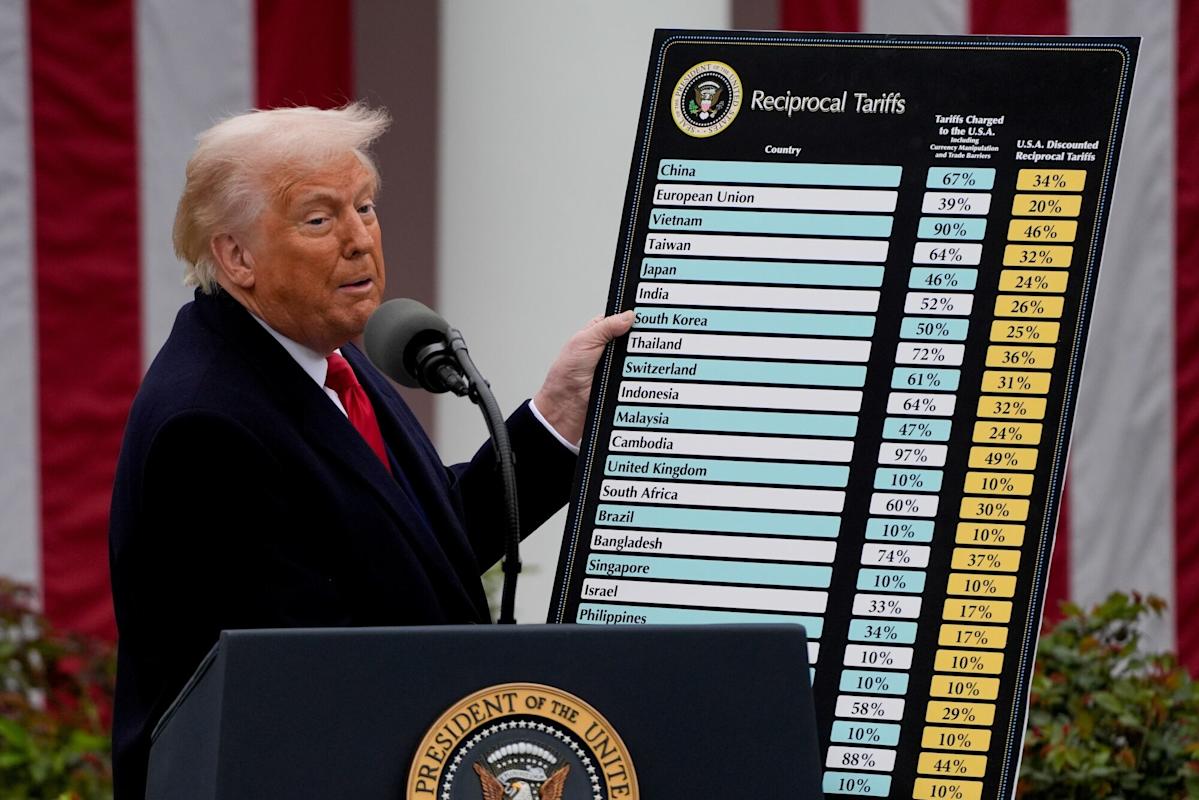

Manufacturing Mirage: Trump's Industrial Policy Threatens U.S. Economic Resilience

2025-03-27 16:00:00

Manufacturing

Strategic Pivot: Abbott Ramps Up Domestic Production Ahead of Potential Trade Barriers

2025-04-16 11:34:47