Green Tech Revolution: How Smart Manufacturing Is Saving the Planet, One Byte at a Time

Manufacturing

2025-03-28 18:05:56Content

How Digital Transformation Revolutionizes Environmental and Operational Sustainability

In today's rapidly evolving technological landscape, digital transformation has emerged as a powerful catalyst for driving both environmental conservation and operational efficiency. By leveraging cutting-edge technologies and innovative strategies, organizations can simultaneously reduce their carbon footprint and optimize their business processes.

Key Ways Digital Transformation Delivers Transformative Benefits

- Smart Resource Management: Digital technologies enable real-time monitoring and intelligent allocation of resources, dramatically reducing waste and minimizing environmental impact.

- Energy Optimization: Advanced analytics and IoT sensors help companies track and optimize energy consumption, leading to significant reductions in carbon emissions and operational costs.

- Paperless Operations: Digital workflows and cloud-based systems eliminate the need for paper documentation, contributing to forest conservation and reducing organizational waste.

- Remote Collaboration: Digital platforms facilitate remote work and virtual meetings, reducing travel-related carbon emissions and promoting a more sustainable work culture.

- Predictive Maintenance: Smart technologies enable proactive equipment maintenance, extending asset lifecycles and reducing unnecessary resource consumption.

By embracing digital transformation, organizations can create a win-win scenario that benefits both their bottom line and the planet, paving the way for a more sustainable and efficient future.

Digital Transformation: Revolutionizing Industrial Efficiency and Sustainability

In the rapidly evolving landscape of modern industry, digital transformation has emerged as a critical catalyst for unprecedented operational excellence and environmental stewardship. As businesses navigate increasingly complex technological ecosystems, the integration of advanced digital technologies is reshaping traditional manufacturing paradigms, driving innovation, and creating sustainable competitive advantages.Unleashing the Power of Digital Innovation: Transform or Get Left Behind

Technological Convergence and Operational Metamorphosis

The digital revolution represents far more than a mere technological upgrade; it's a comprehensive reimagining of industrial processes and strategic capabilities. Manufacturing organizations are experiencing a profound metamorphosis, where intelligent systems, interconnected networks, and data-driven insights converge to create unprecedented operational intelligence. Modern enterprises are discovering that digital transformation transcends traditional boundaries, enabling real-time monitoring, predictive maintenance, and dynamic resource optimization. By leveraging advanced sensors, machine learning algorithms, and sophisticated analytics platforms, companies can transform raw operational data into actionable strategic intelligence.Environmental Sustainability through Intelligent Design

Digital technologies are emerging as powerful instruments for environmental conservation and sustainable industrial practices. Advanced computational models and simulation technologies allow manufacturers to minimize waste, optimize energy consumption, and reduce carbon footprints with remarkable precision. Intelligent systems can now predict equipment performance, schedule maintenance proactively, and identify potential inefficiencies before they manifest. This predictive approach not only extends machinery lifecycles but also significantly reduces unnecessary resource consumption, creating a more sustainable industrial ecosystem.Data-Driven Decision Making and Strategic Resilience

The convergence of artificial intelligence, machine learning, and big data analytics is revolutionizing strategic decision-making processes. Organizations can now generate comprehensive insights that were previously impossible, enabling more nuanced, informed, and agile responses to complex operational challenges. By creating intricate digital twins of physical systems, businesses can simulate various scenarios, test potential interventions, and optimize processes with unprecedented accuracy. This approach transforms risk management from a reactive to a proactive discipline, embedding strategic resilience into organizational DNA.Workforce Transformation and Human-Machine Collaboration

Digital transformation is not about replacing human workers but empowering them with advanced technological capabilities. Sophisticated training programs, augmented reality interfaces, and collaborative robotics are creating new paradigms of human-machine interaction. Employees are increasingly becoming strategic partners with intelligent systems, leveraging technology to enhance creativity, problem-solving, and innovation. This symbiotic relationship is breaking down traditional hierarchical structures and fostering more dynamic, adaptive organizational cultures.Cybersecurity and Technological Integrity

As digital systems become more interconnected, robust cybersecurity frameworks have become paramount. Organizations must develop comprehensive security strategies that protect critical infrastructure, intellectual property, and operational data from emerging digital threats. Advanced encryption technologies, blockchain-based authentication mechanisms, and AI-powered threat detection systems are becoming essential components of modern digital transformation strategies. These technologies ensure not just operational efficiency but also maintain the integrity and trustworthiness of digital ecosystems.Global Competitiveness and Innovation Acceleration

Digital transformation is no longer a competitive advantage but a fundamental requirement for survival in the global marketplace. Companies that successfully integrate advanced technologies can dramatically reduce operational costs, accelerate innovation cycles, and create more responsive, adaptive business models. By embracing a culture of continuous technological learning and strategic experimentation, organizations can position themselves at the forefront of industrial innovation, consistently outmaneuvering competitors and creating new value propositions.RELATED NEWS

Manufacturing

Trade War Threat: How Trump's EU Tariffs Could Shake Up Pharma Supply Chains

2025-04-02 22:01:22

Manufacturing

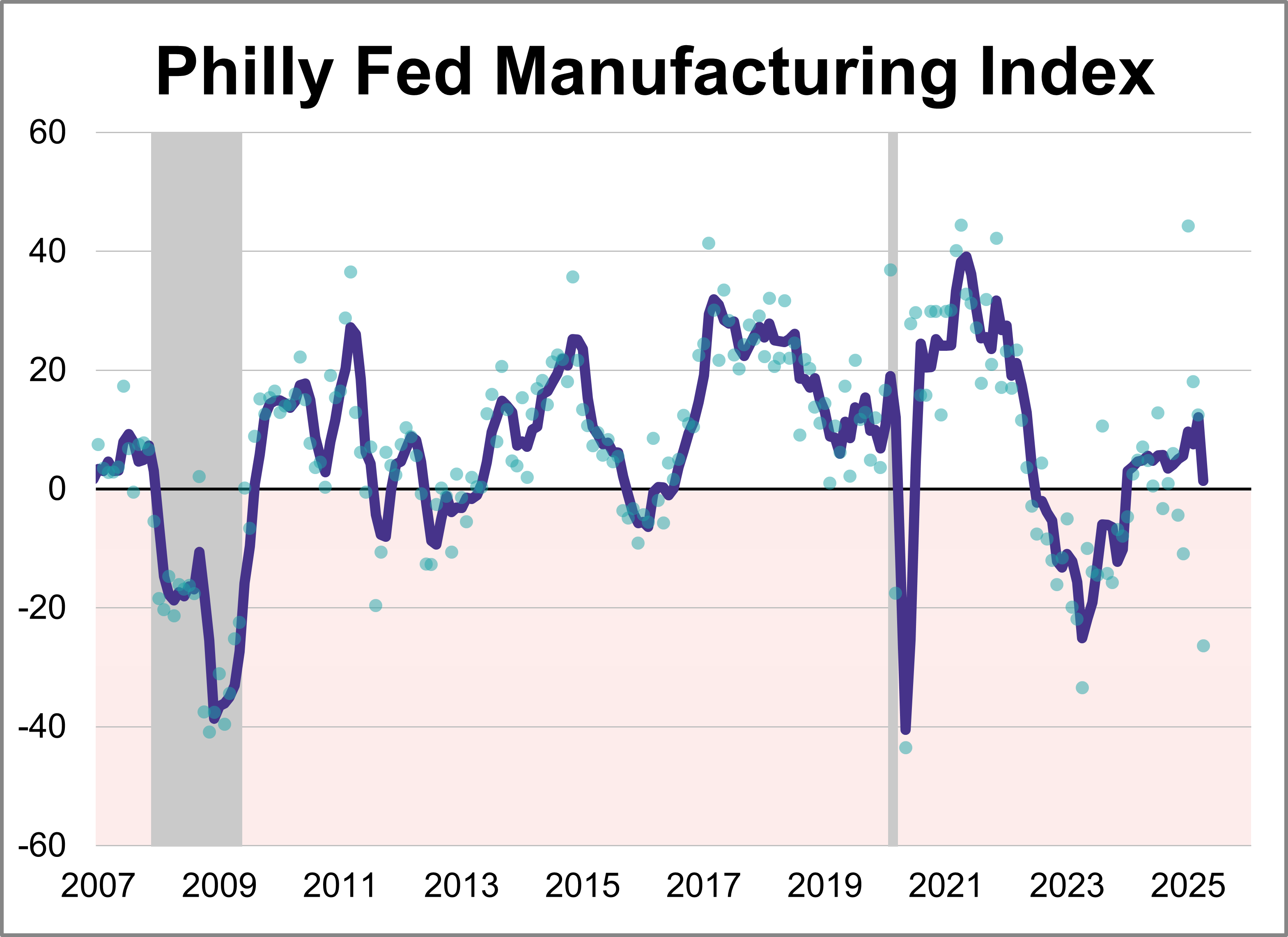

Manufacturing Momentum Stalls: Tariff Tensions Squeeze Factory Floors

2025-03-24 13:45:00

Manufacturing

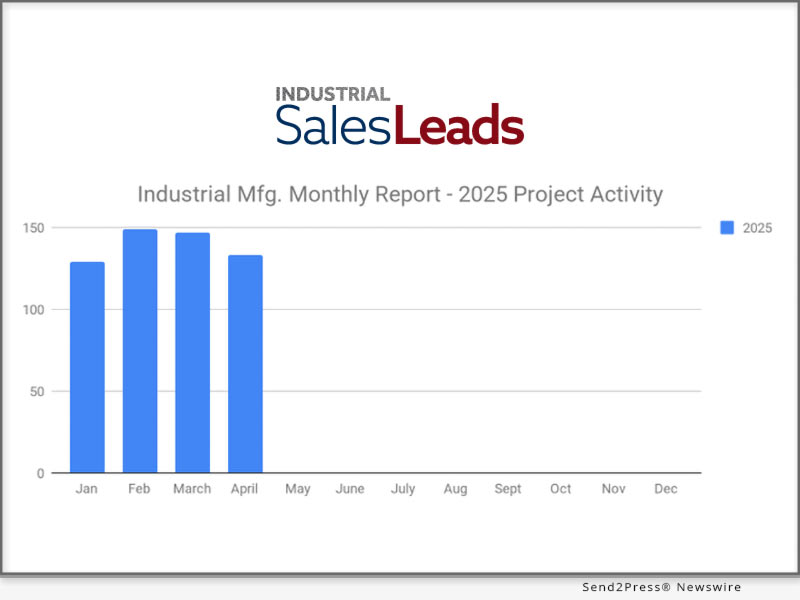

Manufacturing Boom: 133 Mega Projects Set to Revolutionize Industrial Landscape in 2025

2025-05-06 12:00:26